-

03-28 2025

Today we will discuss how color powder is made

A high-speed toner pulverizer is a device used to impact, rub, and shear dry powder materials such as toner to achieve the desired fineness and uniformity.

-

03-22 2025

Today we will talk about the advantages of vertical mixers

The stainless steel vertical drying mixer mainly consists of: motor, barrel body, heating tube, screw, discharge port, cleaning port, pulley, window, ladder, inlet, electrical box, circulating feeding port, feeding port, etc. It has the characteristics of small footprint, compact structure, uniform mixing, and easy operation.

-

02-11 2025

Today we introduce an efficient powder mixer

A horizontal mixer is a machine used for mixing. Under the action of the inner and outer screw belts on the mixing shaft, the material is flipped within the range of the cylinder. The inner screw belt pushes the material from the middle to the two sides, and the outer screw belt pushes the material from the two sides to the center. The material that permeates back and forth moves and changes radially under the rotation of the screw belt, forming a convection cycle that enables the material to be quickly and uniformly mixed in a short time. The two end shaft seals are specially sealed, and the powder liquid does not leak. The cost of replacing sealing consumables is low and easy, making it a high-efficiency mixing equipment with wide applications, strong adaptability, and good effects.

-

12-05 2024

Today we will talk about the vertical mixer for particle drying

Shenyang Jinggong Huazhiyi Machinery Co., Ltd. is a professional manufacturer of mixers, with a professional design team and a skilled operation team. The vertical mixer is suitable for mixing various plastic raw materials and colorants, and the mixing of new and old materials and colorants produces better results. It has the characteristics of strong mixing ability, fast speed, small residual amount, and low energy consumption.

-

09-28 2024

Today, let's talk about how a horizontal mixer works

Horizontal mixers are mainly used for mixing two or more materials, and can achieve fast and uniform mixing in a short period of time. Both ends of the shaft seal adopt dedicated sealing, with no powder or liquid leakage. The replacement cost of sealing consumables is low and easy to replace. Therefore, it is a widely used, adaptable, and efficient hybrid device.

-

09-26 2024

Today, let's talk about an affordable liquid mixer

IBC mixers are widely used in the mixing, dispersion, and dissolution processes of chemical products such as ink dyes, paint inks, resins, adhesives, coatings, inks, pigments, and adhesives. The products are suitable for various industries, such as food factories, daily chemical factories, chemical factories, plastic factories, printing factories, agriculture, and petroleum processing.

-

08-28 2024

Today, let's take a look at the equipment for mixing plastic pellets

The vertical mixer is made of stainless steel material and has heating and drying functions, suitable for use in industries such as food and chemical. The commonly used vertical mixer mainly consists of: motor wheel, motor, barrel body, screw, discharge port, cleaning port, belt pulley, window, ladder, inlet, electrical box, circulating discharge port, feeding port, etc.

-

07-29 2024

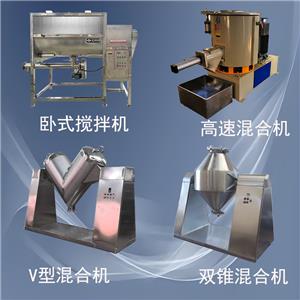

Today we will talk about what powder mixers are available

Shenyang Jinggong Huazhiyi Machinery produces a variety of mixers suitable for mixing powders, such as horizontal mixers, high-speed mixers, high-speed pulverizers, V-type mixers, double cone mixers, etc.

-

06-15 2024

Today we will talk about the stainless steel drying vertical mixer

The working principle of the stainless steel vertical mixer produced by Shenyang Jinggong Huazhiyi Machinery Co., Ltd. is to use the spiral stirring working principle. The material put into the feeding hopper is sent to the upper end of the barrel through the spiral spindle, and then falls in an umbrella shape back to the bottom. This stirring action is continuously carried out to achieve the effect of uniform material mixing. Improved production efficiency and eliminated material waste.

-

05-30 2024

Today, let's talk about how the plastic particle mixer works

The Huazhiyi vertical mixer is suitable for use in industries such as chemical particles, plastic particles, color masterbatch particles, etc. It lifts the material from the bottom feeding port to the top through a screw, and then sprays it down in an umbrella shape. This cycle of mixing achieves uniform and efficient mixing efficiency.