Today, let's talk about how the plastic particle mixer works

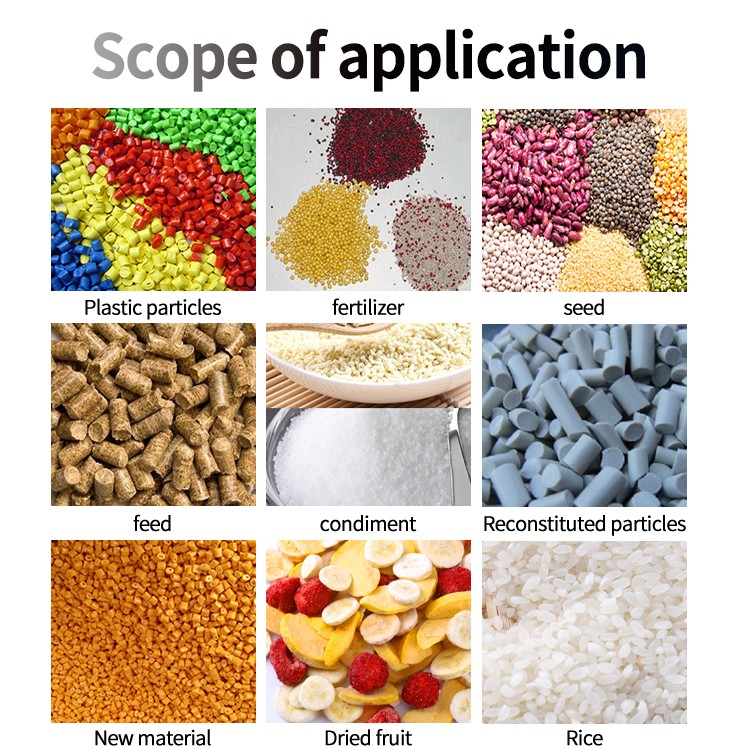

Vertical mixer is suitable for mixing and stirring various plastic raw materials with color masterbatch, such as automotive urea, plastic bottles, PE particles, color masterbatch particles, rubber particle raw materials, recycled materials, crushing materials, sheet materials, film, nozzle materials, and dry powder mixing vertical mixer .

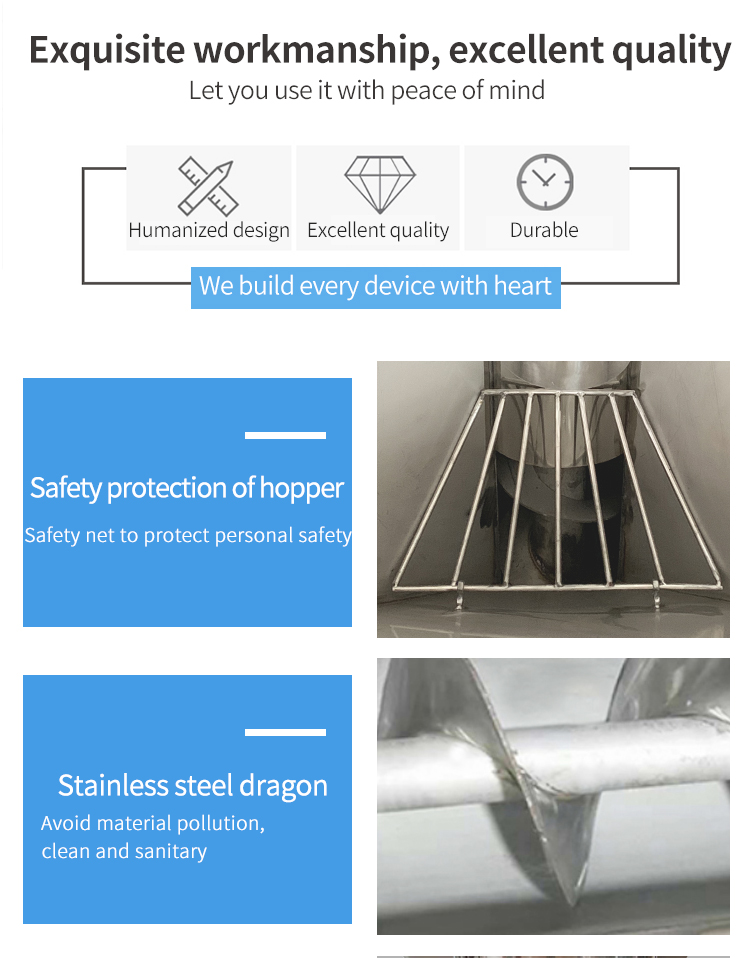

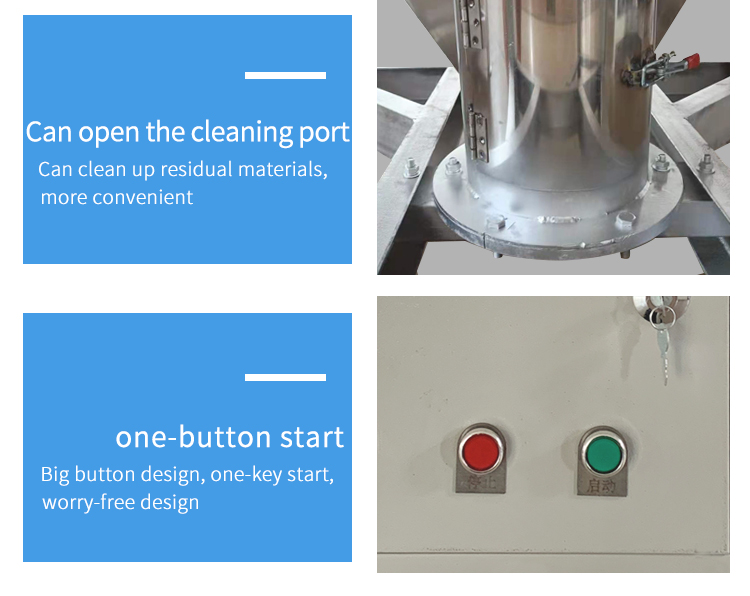

The working principle of a vertical mixer is to use the spiral mixing principle. The materials put into the feeding hopper are sent to the upper end of the barrel through the spiral spindle, and then fall in an umbrella shape back to the bottom. This mixing action is continuously carried out to achieve a uniform mixing of materials. Improved production efficiency without material waste.

Use and maintenance of vertical mixer:

1. Regularly add butter to the mixer bearings.

2. Regularly check the tightness of the belt or chain to prevent slipping, detachment, and breakage.

3. Regularly check the tightness of the machine to ensure smooth operation.

4. Regularly clean the dust on the surface of electrical appliances and check for any damage or leakage of electrical wires.

5. The maintenance of the machine is very important. If regular maintenance is not carried out, it can cause rust and malfunction of the machine. In severe cases, it can seriously damage the machine and shorten its service life.