-

Powder Horizontal Ribbon Blender Mixer

1. Horizontal mixers are widely used in the mixing and mixing of particles, powders, and liquid materials such as chemicals, plastics, rubber, food, medicine, polymers, construction, and fireproof materials. 2. Two-way S-shaped spiral blade, mixing evenly. Long service life and easy maintenance.

Send Email Details -

Color Plastic Particles Mixer Blender

1. The work of the vertical mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then flutter them in an umbrella shape and return to the bottom. 2. In this way, the raw materials are stirred up and down in the barrel, and a large amount of raw materials can be evenly mixed in a short time.

Send Email Details -

Cone Double Screw Mixer Industrial Blender

1. Double cone mixer is a kind of mixing equipment used in construction, food, chemical, material and other industrial production. 2. This type of chemical machinery has a wide adaptability to mixed materials, does not overheat heat-sensitive materials, does not pressure feed and grind granular materials, and mixes materials with large contrast weights and different particle sizes will not cause chip segregation.

Send Email Details -

Vertical Ribbon Mixer Mixing Machine

1. There are many types of vertical mixers. The commonly used vertical mixers are mainly composed of: motor wheel, motor, barrel, screw, discharge port, cleaning port, belt pulley, window, human ladder, entrance, electrical box, and loop blanking port , Feeding port and other components. 2. The work of the vertical mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then fly them in an umbrella shape and return to the bottom, so that the raw materials are stirred up and down in the barrel, and a large amount can be mixed in a short time. The raw materials are uniformly mixed.

Send Email Details -

Pvc High Speed Agitation Mixer Blender

1. High-speed mixers generally refer to high-speed mixers in the plastics industry. Other industries also have high-speed mixers (mixers for lithium batteries), but the structure and principle of the mixer are similar to SHR high-speed mixers. 2. It is suitable for mixing and stirring materials such as powder/granule/auxiliary/toner/color masterbatch/plastic. The barrel adopts an arc-shaped structure, and the special blade structure is mainly used to make the material form a vortex-like high-speed stirring and can be heated and modified

Send Email Details -

Paddle Granule Powder Mixer Machines

Performance parameters: 1. The equipment is made of different types of stainless steel, such as carbon steel, SUS201, SUS304, SUS316L, etc. The contact surface of the material is divided into stainless steel. The whole machine can also be made of stainless steel. 2. There are many models of mixing capacity available with 50-20000L capacity specifications for customers to choose 3. The inside of the barrel is polished and smooth, and the blades are stirred without dead corners, and each batch can be mixed evenly in 5-10 minutes.

Send Email Details -

Hot

Mineral Powder Mixer Ribbon Type Stainless Steel Horizontal Mixer

The thickened barrel of the mineral powder mixer is made of stainless steel, which is resistant to corrosion and oxidation, and is more durable. Enlarge the screw-belt stirring blade, the contact area with the material is large, the stirring and mixing are more uniform, and the discharge is relatively clean. The national standard motor reducer is powerful and durable. Large bearing capacity and long service life. Butterfly valve discharge, adjustable opening, smooth discharge, high production efficiency.

Send Email Details -

Grain Powder Blender Blender For Chemical

1. The equipment is made of different types of stainless steel, such as carbon steel, SUS201, SUS304, SUS316L, etc. The contact surface of the material is divided into stainless steel. The whole machine can also be made of stainless steel. 2. All-stainless steel central shaft and single or double "S"-shaped blades, mixing materials quickly and evenly; 3. The discharge port has a knife type, a wall type, a valve, a manual, an automatic (pneumatic, electric) waterproof, dust-proof and no leakage.

Send Email Details -

Hot

Stainless Steel Mixer Vertical Blender

1. Transmission connection part: This machine adopts a cycloid pinwheel reducer to drive the main shaft to rotate. The main working part of the main machine adopts nylon pin 2. Which is the gear and transmission drive of the transmission connector, which is convenient for assembly and maintenance;

Send Email Details -

Hot

Horizontal Blender Mixing Equipment Machine

1. The horizontal mixer turns the materials in the barrel under the action of the inner and outer spiral belts on the mixing shaft. The inner spiral belt pushes the material from the middle to the two sides, and the outer spiral belt pushes the material from the two sides to the center. The mixed materials move and change in the radial direction under the rotation of the spiral belt, thus forming a convective circulation. Agitation of the above movement 2. The materials can be mixed quickly and evenly in a short time. The shaft seals at both ends adopt special seals, and there is no powder leakage. The replacement cost of sealing consumables is low and easy to replace. Therefore, it is a kind of wide application, strong adaptability and good effect. Mixing equipment

Send Email Details -

Hot

Dispersing Carbon Steel Stainess Stand Mixer

1. The stirring is transmitted to the main shaft by the transmission wheel through the pin coupling. 2. Turn the materials evenly in the mixing chamber, so that the materials can be fully mixed, thereby greatly reducing the residual amount of materials. 3. Wear-resistant, the use of cycloid reducer has the characteristics of compact structure, convenient operation, uniform mixing, and convenient discharge and conveying.

Send Email Details -

Hot

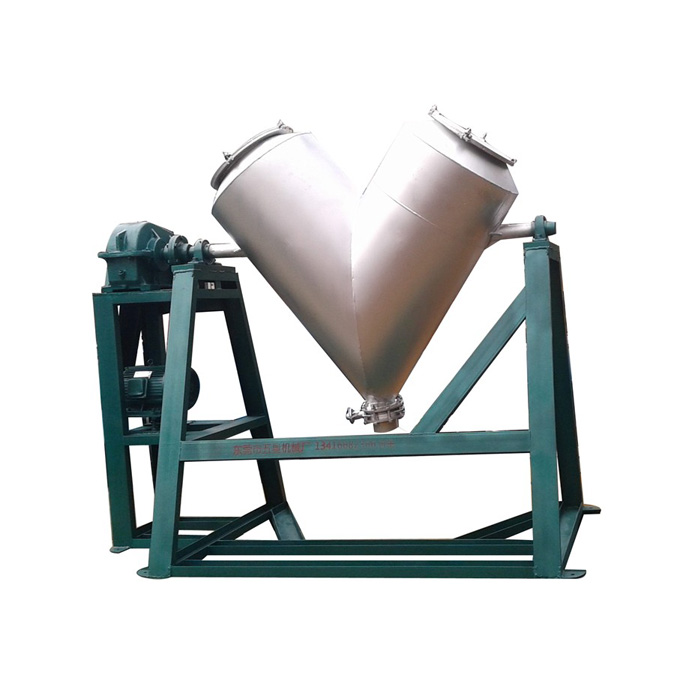

V-type Conical Mixer Blender Machine

1. The V-type mixer series products are high-efficiency asymmetric mixers, which are suitable for mixing powder or granular materials in the chemical, food, medicine, feed, ceramic, metallurgical and other industries. 2. The machine has a reasonable structure, simple operation, airtight operation, convenient feeding and discharging, and the cylinder (manual or vacuum feeding) is made of stainless steel, which is easy to clean. It is one of the basic equipment of the enterprise.

Send Email Details