Today we will talk about the advantages of vertical mixers

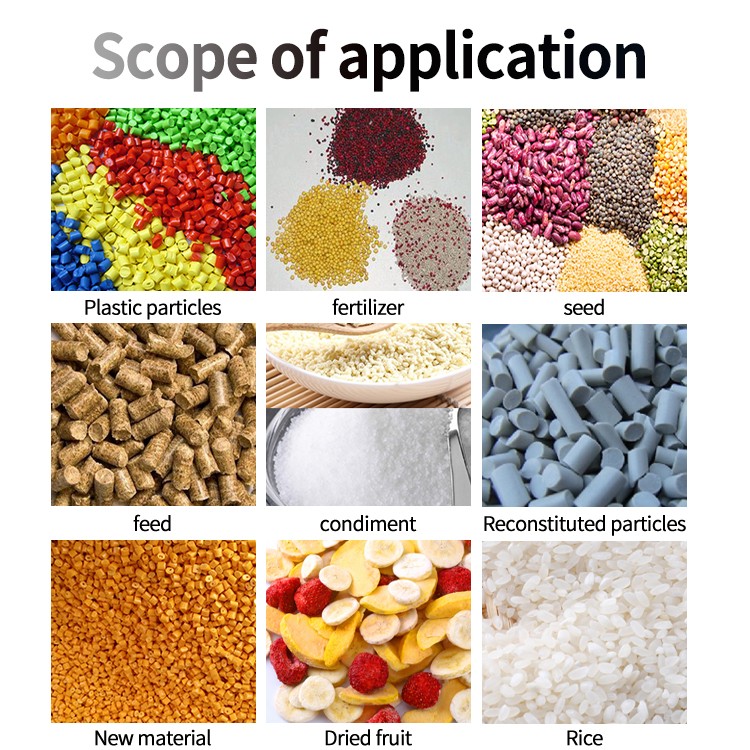

The vertical mixer is suitable for various plastic raw materials, granular materials, recycled materials, crushed materials, sheets, films, nozzle materials, and some dry powder mixing equipment. It is used for color mixing of new, old materials, and color masterbatches, as well as for plastic dyeing, granulation, modification, recycling and processing of recycled materials. The effect of plastic dyeing is very good!

The working principle of a vertical mixer is to use the spiral mixing principle. The materials put into the feeding hopper are sent to the upper end of the barrel through the spiral spindle, and then fall in an umbrella shape back to the bottom. This mixing action is continuously carried out to achieve a uniform mixing of materials. Improved production efficiency without material waste.

Advantages of vertical mixing mixer:

1. Vertical design: easy to operate and easy to maintain.

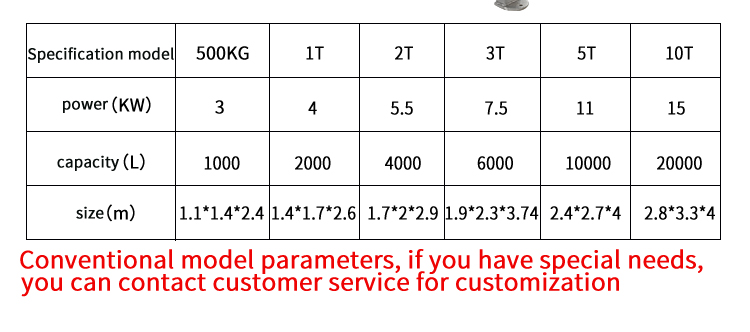

2. Capacity optional: A regular 1-10 ton model is available for customers to choose from.

3. Easy to clean: SUS2O1 stainless steel manufacturing, easy to clean.

4. Uniform mixing: The stirring speed is fast and can ensure the consistency of each batch of materials.

5. Cost saving: The advantages of small investment, less land occupation, labor saving, and high efficiency.

6. Support customization and can be customized according to the actual needs of customers.

Vertical mixer usage and maintenance:

1. Regularly add butter to the bearings of the mixer.

2. Regularly check the tightness of the belt or chain to prevent slipping, detachment, and breakage.

3. Regularly check the fastening of the machine to ensure smooth operation.

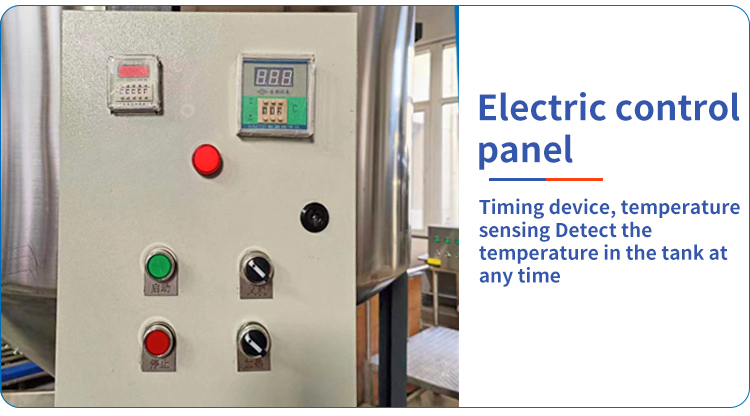

4. Regularly clean the surface dust of electrical appliances and check whether the electrical wires are damaged or have leakage.

5. The maintenance of machines is very important. If regular maintenance is not carried out, it can cause rusting and malfunction of the machine, and in severe cases, it can seriously damage the machine and shorten its service life.

Advantages of vertical mixing mixer:

1. Vertical design: easy to operate and easy to maintain.

2. Capacity optional: A regular 1-10 ton model is available for customers to choose from.

3. Easy to clean: SUS2O1 stainless steel manufacturing, easy to clean.

4. Uniform mixing: The stirring speed is fast and can ensure the consistency of each batch of materials.

5. Cost saving: The advantages of small investment, less land occupation, labor saving, and high efficiency.

6. Support customization and can be customized according to the actual needs of customers.