Today, let's talk about the working principle of the screw conveyor

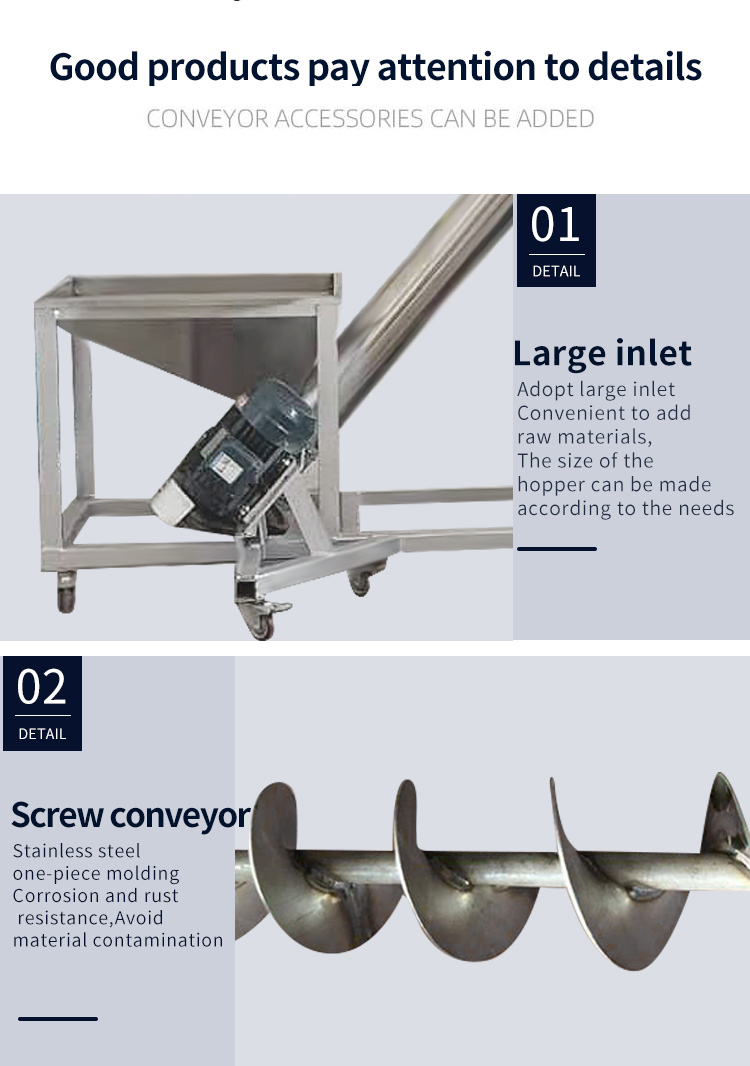

A tubular screw conveyor is a mechanical device that uses an electric motor to drive the screw to rotate, thereby transporting materials from the feed hopper to the discharge port for conveying. Spiral conveyors are divided into three types: horizontal, inclined, and vertical. They are mainly used for horizontal, inclined, and vertical lifting.

Stainless steel screw conveyors are widely used in industries such as food, seasoning, building materials, chemical, power, metallurgy, coal mine charcoal, and grain. Suitable for horizontal or inclined conveying of powdery, granular, and small block materials. Spiral machines are not suitable for conveying materials that are prone to spoilage, high viscosity, and clumping.

Advantages of screw conveyor: It has the advantages of simple structure, small cross-sectional area, good sealing, easy operation, easy maintenance, and convenient enclosed transportation.

Characteristics of Spiral Conveyor:

1. High load-bearing capacity, safe and reliable

2. Strong adaptability, easy installation and maintenance, long service life

3. The whole machine has a small volume and fast speed, ensuring fast and uniform conveying

4. The whole machine has low noise, strong adaptability, and flexible layout of import and export positions

5. Good sealing performance, the shell is made of seamless steel pipe, and the two ends are connected by flanges to form a whole, with good rigidity.

Maintenance and upkeep of screw conveyor:

1.Before starting the screw conveyor, first check whether the power supply is normal, ensure that the motor power line is connected correctly, and the supply voltage is normal. Check the daily operation duty records to confirm that there are no abnormalities in the equipment.

2. Regularly inspect the electrical wiring of the equipment to ensure smooth operation and no abnormal noise.

3. Check the electrical wiring and operation status of the equipment every week to ensure smooth operation and no abnormal noise.

4. Regularly replace lubricating oil to maintain good lubrication status of all components of the equipment.

5. Regularly check the oil level and color of the gearbox, and add or replace lubricating oil if necessary.

Daily inspection and maintenance:

1. Appearance inspection: Regularly inspect the appearance of the screw conveyor to see if there are any deformations, cracks, or corrosion. Check if bolts, nuts, and other fasteners are loose, and tighten them if necessary.

2. Bearings and lubrication: Regularly check the wear of bearings to ensure good lubrication and avoid overheating and wear. Check the quantity and quality of lubricating oil or grease, and promptly replenish or replace them.

3. Spiral blade inspection: Check the wear of the spiral blades, especially when conveying abrasive materials. Severely worn blades should be replaced in a timely manner to avoid affecting conveying efficiency and increasing equipment load.

4. Inspection of Drive Devices: Check the working status of drive devices such as motors and reducers to ensure smooth operation, no abnormal noise or vibration.