Today we will talk about how to distinguish between mixing tanks and reaction vessels

In terms of functionality, both mixing tanks and reaction vessels are containers used for stirring and mixing; And they are similar in appearance and structure, both can be used for mixing liquid-liquid, solid-liquid, and even have the same installation method.

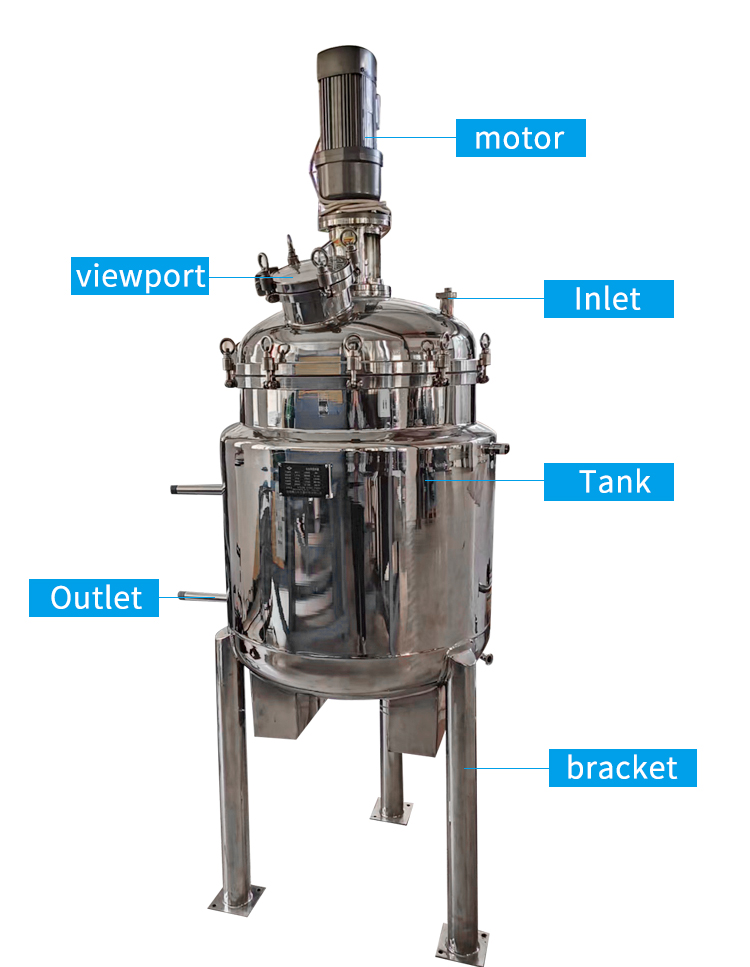

Mixing tanks and reaction vessels also differ in structure and usage scenarios. The structure of the mixing tank is relatively simple, with a flat top cover that can be directly observed and operated; The upper cover of the reaction kettle is mostly a head or conical structure, and observation requires auxiliary equipment such as sight glasses and level gauges.

There are also differences in sealing and operating methods between mixing tanks and reaction vessels: mixing tanks can be sealed with mechanical seals or packing seals as needed; And the reaction kettle must be sealed mechanically to ensure its sealing performance under high temperature and high pressure. In addition, the operation process of the mixing tank is relatively simple and the production cost is low; The operation and maintenance of the reaction kettle are relatively complex, and the production cost is high

Mixing tanks and reaction vessels are widely used in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research. This device can select heating and cooling devices according to the process requirements of the user's product to meet different process and production needs. Heating methods include jacket electric heating and coil heating. The device has a reasonable structural design, advanced technology, durability, simple operation, and convenient use. It is an ideal equipment with low investment, fast production, and high return.

Several characteristics of insulation structure for stainless steel reaction kettle:

1. Packing sealing is usually used under normal or low pressure conditions, with a pressure of less than 2 kilograms.

2. In general, mechanical seals are used for medium pressure or vacuum situations, with a pressure of negative pressure or 4 kilograms.

3. Magnetic sealing will be used under high pressure or high volatility of the medium, usually when the pressure exceeds 14 kilograms.

Requirements for the use of the reactor sealing device:

1. Packing sealing is usually used under normal or low pressure conditions, with a pressure of less than 2 kilograms.

2. In general, mechanical seals are used for medium pressure or vacuum situations, with a pressure of negative pressure or 4 kilograms.

3. Magnetic sealing will be used under high pressure or high volatility of the medium, generally with a pressure greater than 14 kilograms. Except for magnetic seals that use water cooling, other sealing forms will increase the cooling water jacket at temperatures greater than 12 degrees Celsius.