Today we will introduce a device used for classification

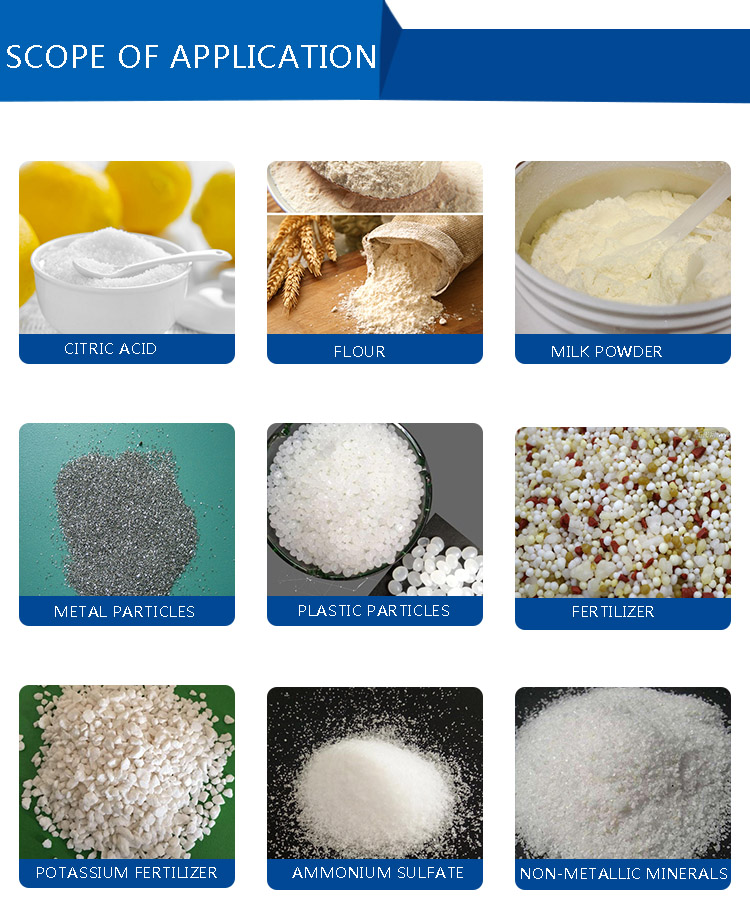

Chemical industry: resin, coating, cosmetics, paint, etc.; food industry: sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, etc.; metal, metallurgy and mining industry: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory, kaolin, lime, aluminum oxide, heavy calcium carbonate, quartz sand, etc.

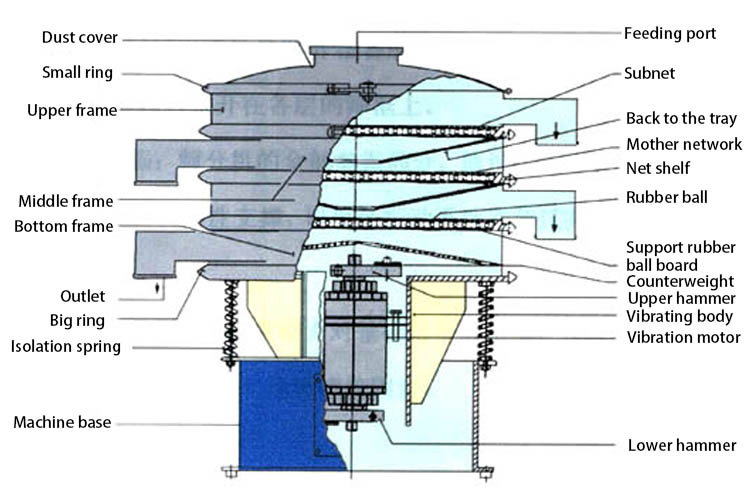

CThe working principle of a vibrating screen is to achieve material screening through the reciprocating rotary vibration generated by the oscillator excitation. Specifically, the upper rotating weight of the oscillator produces a planar rotational vibration on the screen surface, while the lower rotating weight produces a conical rotational vibration on the screen surface. The combined effect of the two causes the screen surface to produce a complex rotational vibration. This vibration trajectory is projected as a circle in the horizontal plane and an ellipse in the vertical plane. By adjusting the excitation force of the up and down rotating heavy hammer, the amplitude can be changed; By adjusting the spatial phase angle of the upper and lower hammers, the curve shape of the sieve surface motion trajectory can be changed and the motion trajectory of the material on the sieve surface can be altered.

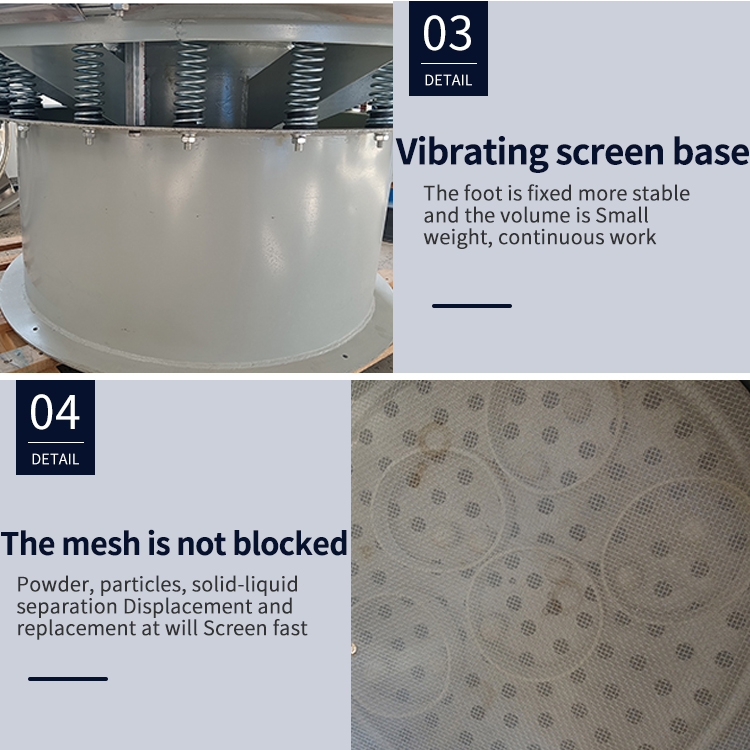

Characteristics of vibrating screen products:

1. High efficiency, exquisite and durable design, capable of screening any powder or mucus.

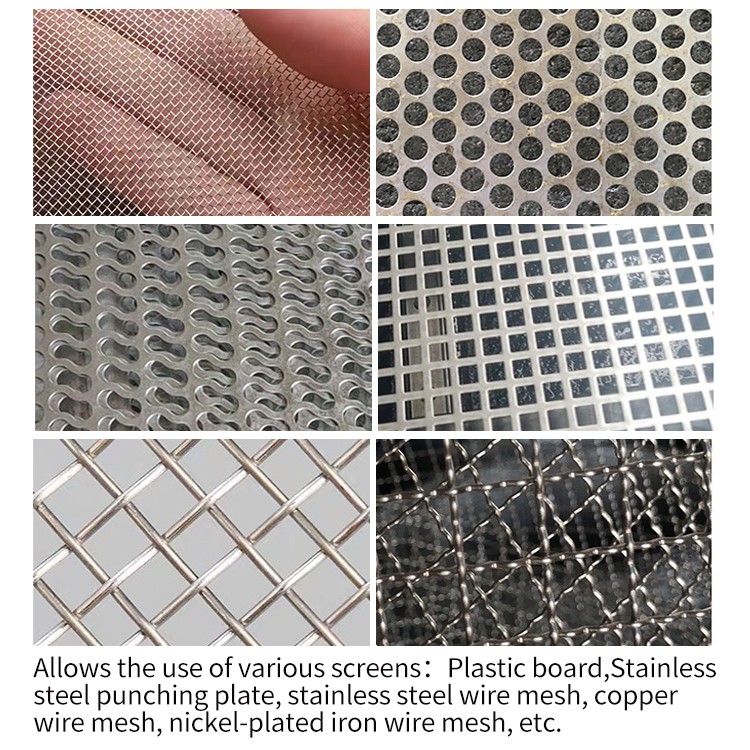

2. Easy to change mesh, easy to operate, and easy to clean.

3. The mesh is not blocked, the powder does not fly, and can be sieved up to 500 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged and can be operated continuously.

5. Unique mesh design, long-lasting use of the screen, fast mesh replacement, only 3-5 minutes.

6. Small size, space saving, and convenient mobility.

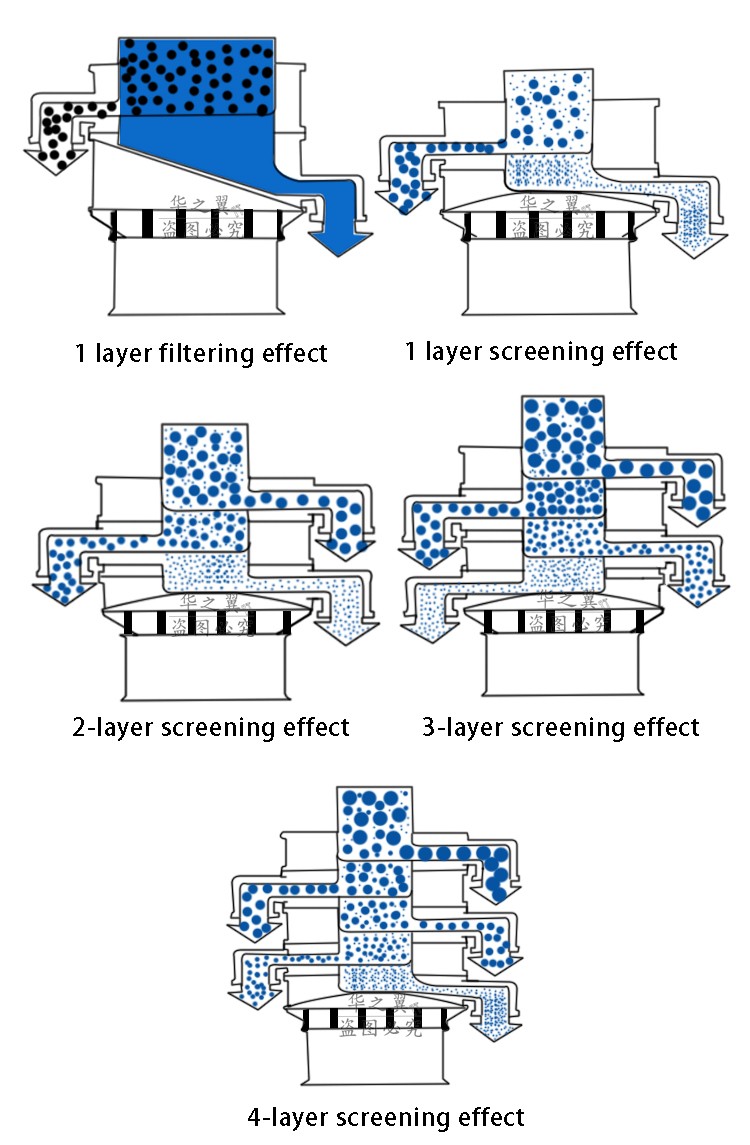

7. The screening machine can reach five layers, and it is recommended to use three layers.

Application scenarios and advantages of vibrating screens

Vibration screens are widely used in various scenarios such as material screening, classification, fragmentation, and dehydration. Its advantages include:

High throughput: The larger screening area enables high efficiency in material screening, with a production capacity of up to 20 tons per hour.

Multi layer separation: Up to 5 levels of grading can be achieved in a single operation, providing precise particle size distribution.

Adjustable: Equipped with an adjustable vibration motor, it can achieve different speeds and vibration levels according to the settings.

Efficient screening: It can effectively improve the efficiency and quality of aged garbage treatment, and is suitable for fine screening.