Today we will discuss how color powder is made

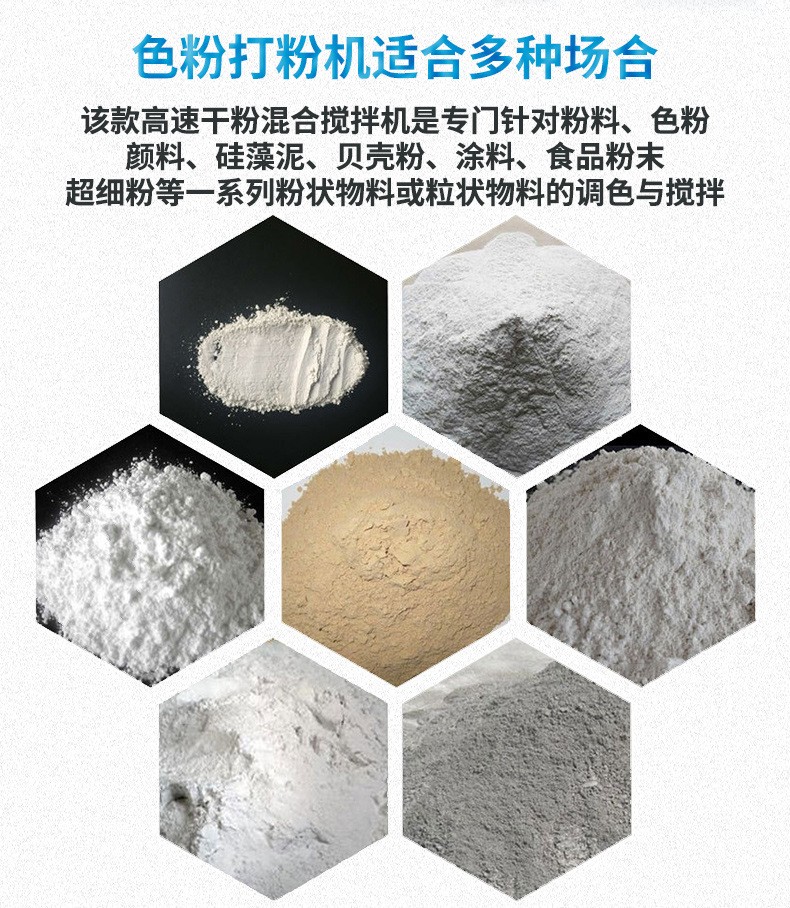

Color powder mixer is suitable for mixing and stirring various plastic pigments and colorants in the plastic industry, coating industry, ink industry, rubber industry, and other industries; Can be equipped with multiple barrels per machine. The materials in contact with the equipment and raw materials are all made of high-quality stainless steel; Exquisite workmanship, smooth barrel walls and paddles are very convenient for cleaning. The stirring knife makes the mixing of color powder and pigment more uniform and fast.

The small pulverizer is composed of a stainless steel upper cover and lower body pulverization chamber, which is closed with screw fasteners. The high-speed operation of the upright motor drives the horizontally installed crushing blades to perform impact and shear crushing on the material. Due to being stirred in a closed space, the crushing effect of crushed objects is relatively uniform and suitable for dry materials. The machine has a swinging design, which facilitates the dumping and cleaning of materials.

Instructions for use of high-speed mixer:

1. This machine utilizes the principle of mandatory mixing to pour materials into a barrel and achieve uniform mixing under high-speed stirring.

2. After the installation of this machine is completed, it is necessary to test the machine before initial use, check the direction of motor operation, whether there is any abnormal noise during machine operation, and whether the operation is smooth.

3. If everything is normal during the empty machine trial run, the work before feeding can proceed

4. Clean the machine to ensure that there are no impurities contaminating the raw materials

5. Confirm whether the inlet door on the barrel is properly sealed and whether the pressure port is securely fastened.

Precautions for powder making machine:

1. For the personal safety of users, the power supply must be grounded.

2. The crushed material must be dry and should not be processed into damp and oily traditional Chinese medicine.

3. The crushed medicine should not exceed half of the capacity of the crushing tank.

4. Generally, traditional Chinese medicine can be crushed in half a minute, while hard medicine can be crushed in one minute.

5. This machine cannot be used continuously for a long time, and the startup time should not exceed 5 minutes each time. If the processing quantity is large, it should be used intermittently to prevent bearing overheating and motor damage

6. Do not activate the switch when the upper cover is opened.

7. After long-term use, if the carbon brush and blade are severely worn, they need to be replaced.

8. Regularly check the screws of the blade, which must be tightened.