Today we will talk about what powder mixers are available

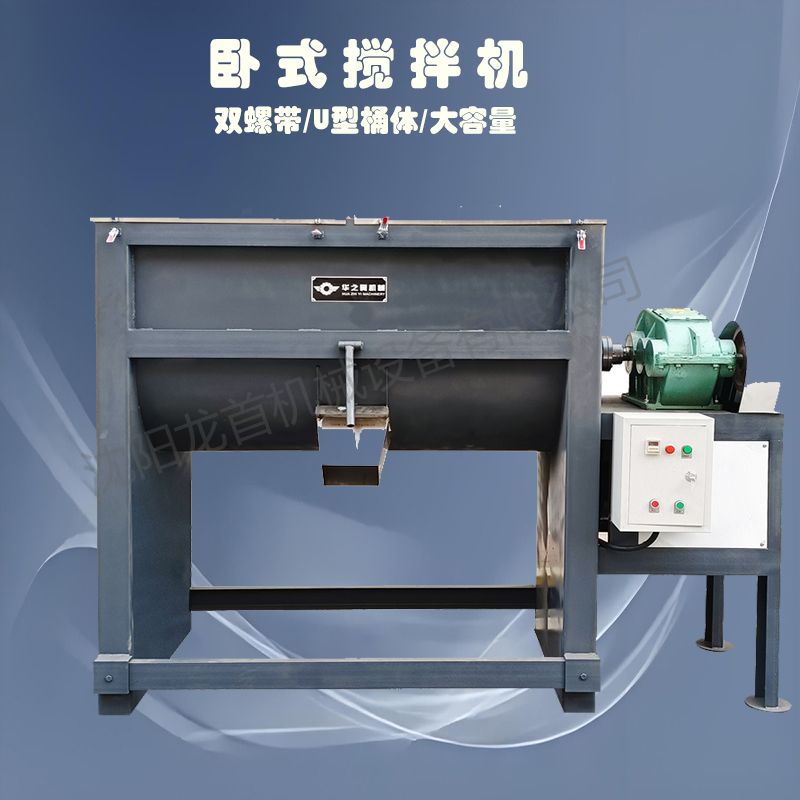

The horizontal dry powder mixer is suitable for the mixing of various dry powders and fine granular materials, such as starch, flour, milk tea powder, milk powder, chocolate powder, seasoning powder, Panax notoginseng powder, putty powder, coating powder, cement, etc., and is uniformly stirred and mixed.

The working principle of a horizontal mixer is to arrange double-layer spiral blades on the transmission spindle, with internal and external spirals (small spiral belts) conveying materials to the outside, and external spirals (large spiral belts) pushing materials inward. Under the convective motion of the double spiral belts, the materials form a low power and high efficiency mixed environment. The inner and outer diameter screws installed on the mixing shaft drive the material inside the barrel, causing the agitator to flip the material within a certain range inside the barrel. When the mixing device is working, the inner screw drives the material near the axis to rotate axially, pushing it from the inside to both sides. The outer screw drives the material near the barrel wall to rotate axially, pushing it from both sides to the inside, allowing the mixed material to mix evenly in a short period of time.

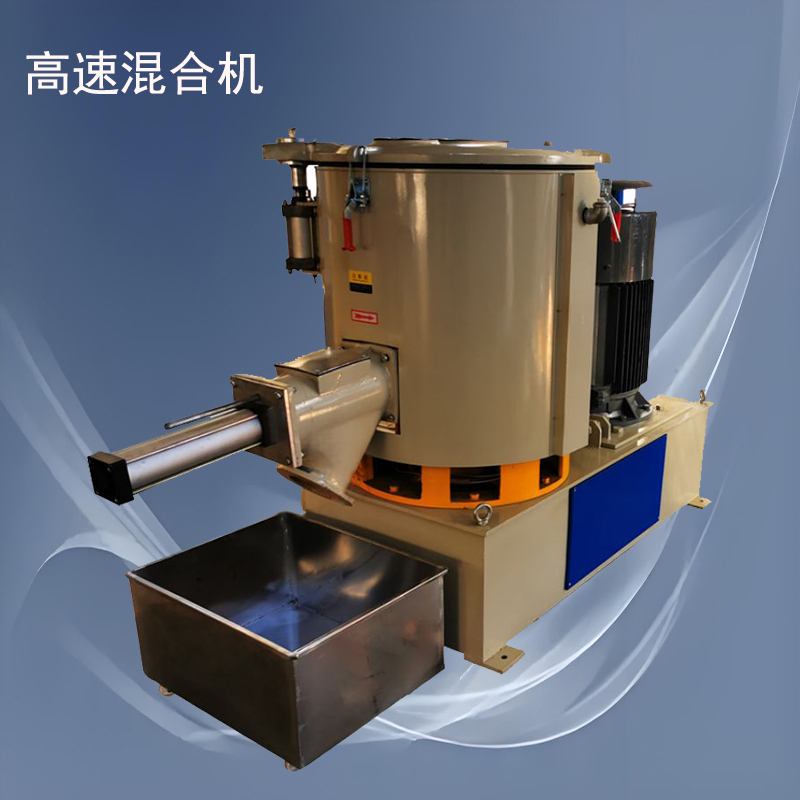

The main shaft is directly driven to rotate by the electric motor through the belt pulley and gearbox. The rotating blades with special shapes installed on the main shaft rotate accordingly. Under the action of centrifugal force, the material rises along the conical wall of the fixed mixing tank and is in a rotary motion state, forming a swirling motion. It is easy to mix materials of different densities evenly in a short time, and the mixing efficiency is more than twice that of a general mixer. The various raw materials and binders involved in the mixing are fed into the upper inlet, and the mixed materials are discharged from the side discharge port of the mixing tank. To meet the mixing requirements of certain materials, the equipment is equipped with insulation sleeves that can cool, heat, and insulate the materials.

The double cone mixer transfers powder or granular materials into a double cone container through vacuum conveying or manual feeding. As the container rotates continuously, the materials undergo complex impact movements in the container to achieve uniform mixing. This machine is energy-saving, easy to operate, has low labor intensity, and high work efficiency.

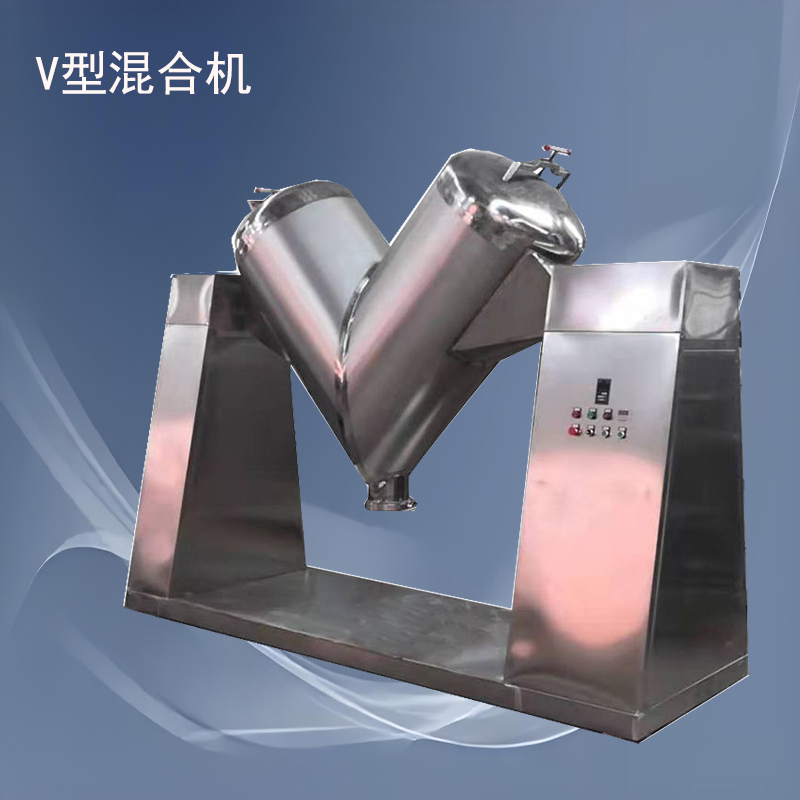

The working principle of the V-type mixer is mainly achieved through the rotation of the container and the free fall motion of the material to achieve mixing. This type of mixer typically consists of two asymmetric cylinders forming a V-shaped structure. During operation, the motor drives the V-shaped bucket to rotate through a reducer and coupling. This rotational motion causes the materials inside the bucket to move up, down, left, and right under the action of gravity, thereby achieving mixing. In addition, V-type mixers are usually designed with inlet and outlet valves, where materials enter the mixing drum from both ends and are evenly mixed before being discharged from the bottom outlet. Some V-type mixers are also designed with mixing blades or forced circulation mixing systems inside to enhance the mixing effect. The entire process is simple and efficient, suitable for mixing powdered and granular materials, and widely used in industries such as pharmaceuticals, chemicals, and food.