-

08-28 2024

Today, let's take a look at the equipment for mixing plastic pellets

The vertical mixer is made of stainless steel material and has heating and drying functions, suitable for use in industries such as food and chemical. The commonly used vertical mixer mainly consists of: motor wheel, motor, barrel body, screw, discharge port, cleaning port, belt pulley, window, ladder, inlet, electrical box, circulating discharge port, feeding port, etc.

-

08-24 2024

What is the crushing method of the universal crusher?

The universal crusher utilizes the high-speed relative motion between the movable toothed disc and the fixed toothed disc to achieve crushing of the crushed material through a combination of tooth impact, friction, and material impact with each other. The structure of this machine is simple, sturdy, runs smoothly, and has good crushing effect. The crushed material can be directly discharged from the grinding chamber of the main machine, and the particle size can be obtained by replacing different aperture mesh screens. In addition, the machine is made of all stainless steel. The inner wall of the casing has been machined to achieve a smooth surface, changing the previous rough and powdery phenomenon of the inner wall of the model, making the production of drugs, food, chemicals, etc. more in line with national standards and meeting GMP requirements.

-

08-22 2024

Today, we will introduce a stainless steel mixing tank

The liquid mixing tank can be made of materials such as SUS304.SUS316 stainless steel according to the process requirements of the user's product, as well as equipped with heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. This equipment has the characteristics of reasonable structural design, simple operation, and convenient use.

-

08-16 2024

Today we will introduce the equipment suitable for packaging and conveying

Belt conveyors are widely used in various industries such as home appliances, electronics, appliances, machinery, tobacco, injection molding, postal and telecommunications, printing, food, etc., for the assembly, testing, debugging, packaging, and transportation of objects. Belt conveyors have strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can conveniently implement programmed control and automated operation. The continuous or intermittent movement of conveyor belts is used to transport items weighing less than 100KG or in powder or granular form. It runs at high speed, smoothly, with low noise, and can be transported up and down hills.

-

08-08 2024

Today we introduce a planetary mixing pot for boiling

Planetary mixing pot is a new type of stir frying pan with no dead center mixing and stirring equipment. It has a novel planetary stirring form. There are two or three multi-layer blade agitators and one to two automatic scrapers inside the kettle. The agitators revolve around the axis of the kettle body while rotating around their own axis at different speeds, causing the materials to undergo complex movements inside the kettle body, subjected to strong shear and rubbing.

-

07-29 2024

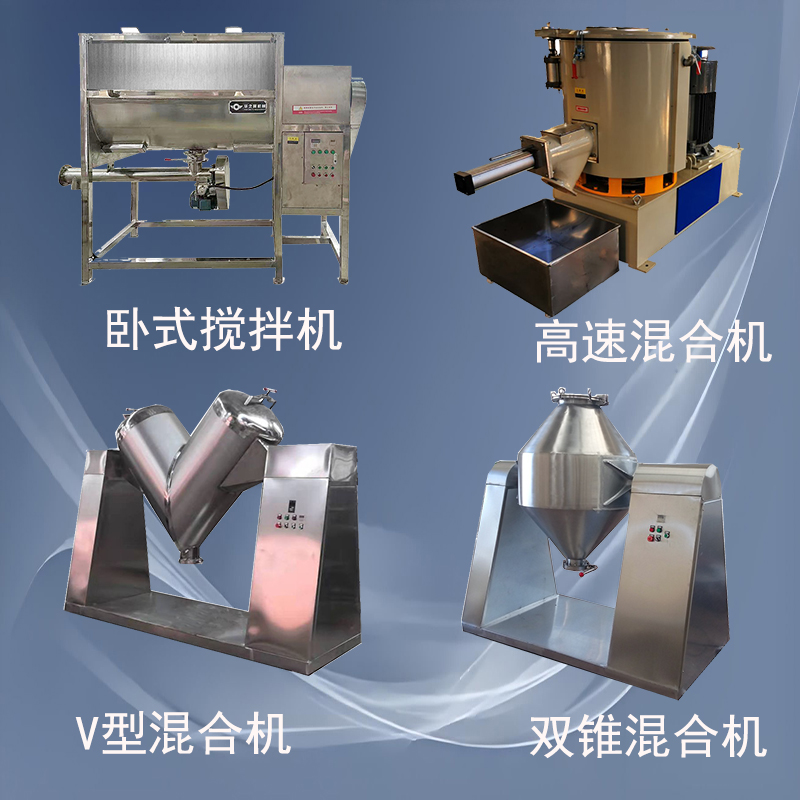

Today we will talk about what powder mixers are available

Shenyang Jinggong Huazhiyi Machinery produces a variety of mixers suitable for mixing powders, such as horizontal mixers, high-speed mixers, high-speed pulverizers, V-type mixers, double cone mixers, etc.