-

10-06 2024

Today we introduce a high shear vacuum reactor

Stainless steel reaction vessels are made of stainless steel, mostly made of 304 or 316L stainless steel, meeting production standards. When mixing materials, frame mixing is mainly used to stir and disperse the materials evenly in a short period of time. At the same time, customers can choose different kettle, frame, anchor, and slurry types to mix the items, ensuring that the products are fully and evenly dispersed.

-

09-28 2024

Today, let's talk about how a horizontal mixer works

Horizontal mixers are mainly used for mixing two or more materials, and can achieve fast and uniform mixing in a short period of time. Both ends of the shaft seal adopt dedicated sealing, with no powder or liquid leakage. The replacement cost of sealing consumables is low and easy to replace. Therefore, it is a widely used, adaptable, and efficient hybrid device.

-

09-26 2024

Today, let's talk about an affordable liquid mixer

IBC mixers are widely used in the mixing, dispersion, and dissolution processes of chemical products such as ink dyes, paint inks, resins, adhesives, coatings, inks, pigments, and adhesives. The products are suitable for various industries, such as food factories, daily chemical factories, chemical factories, plastic factories, printing factories, agriculture, and petroleum processing.

-

09-10 2024

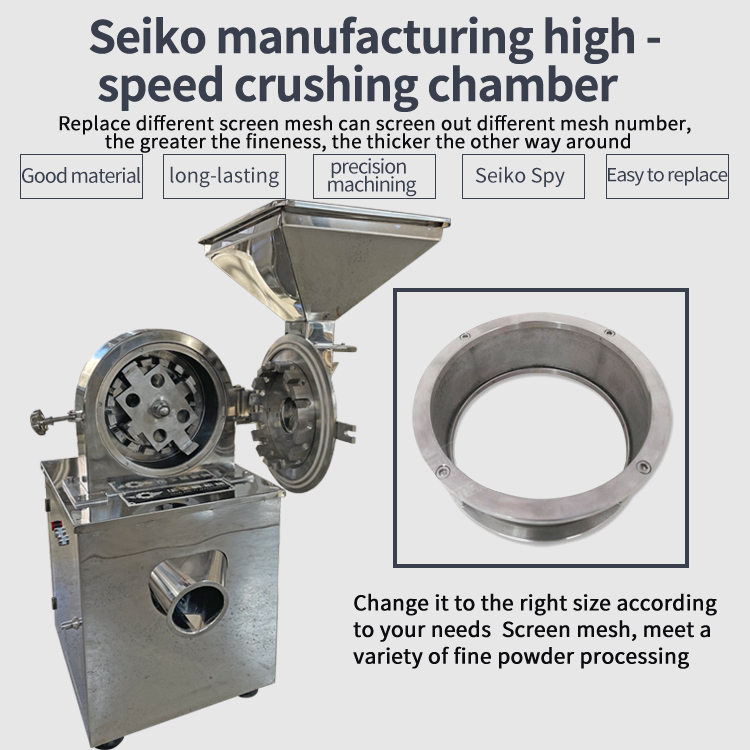

Today we introduce a stainless steel universal crusher

The fineness of the universal crusher can be adjusted between 20-120 mesh, with high output, fine particle size, and low noise The advantages of low energy consumption, simple maintenance, and easy installation are particularly suitable for non oily, low viscosity.Heat sensitive and fibrous (e.g. Dendrobium, chili, ginger, cassava chips, peanuts, soybeans, star anise) Cinnamon, white sugar, salt crystals, Chinese herbs,grains, tea, cosmetics, pearls Grinding and processing of low to medium hardness materials such as chemical coatings.

-

09-04 2024

Today, let's talk about the liquid heating mixing reactor

Stainless steel reaction vessels have the characteristics of rapid heating, high temperature resistance, corrosion resistance, hygiene, no environmental pollution, no need for boiler automatic heating, and convenient use. They are widely used in petroleum, chemical, rubber, dyes, food, and other processes such as vulcanization, nitrification, hydrogenation, alkylation, polymerization, and condensation.

-

08-30 2024

Today, let me introduce how to choose a mixing tank and a reaction vessel

Reaction vessels, also known as stirred tanks, are widely used in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research. This device can be made of materials such as carbon steel and stainless steel according to the process requirements of the user's product, and equipped with heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. This equipment has a reasonable structural design, advanced technology, durability, and is characterized by simple operation and easy use. It is an ideal chemical equipment with low investment, fast production, and high returns.