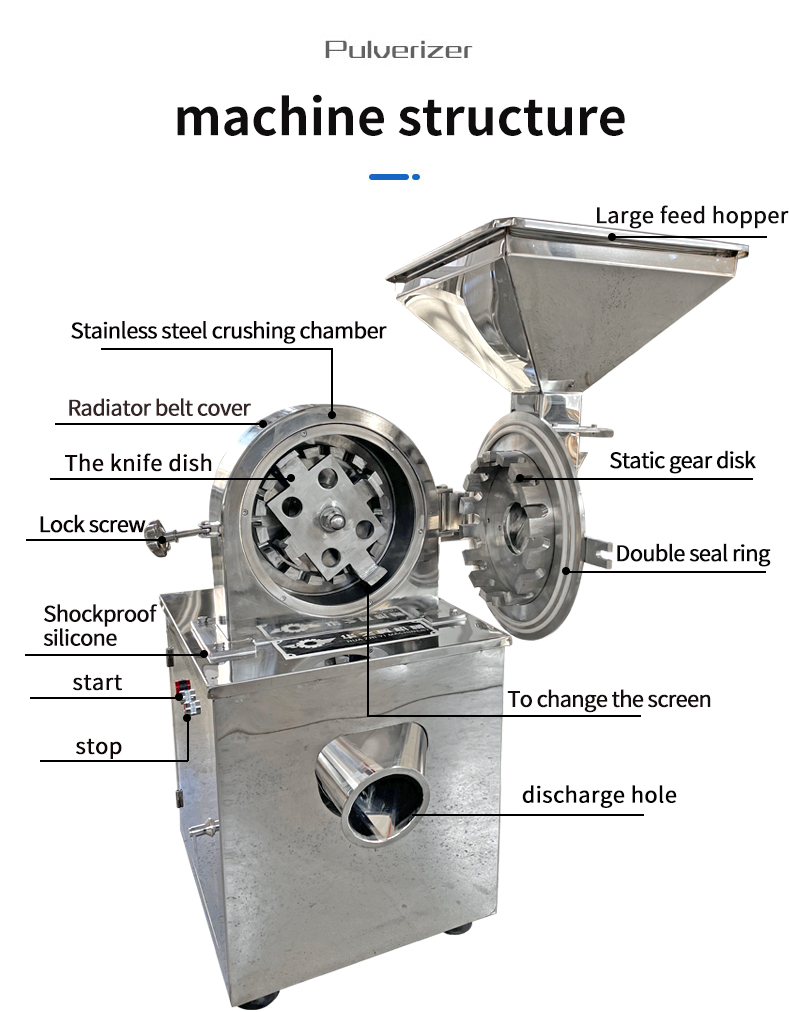

Today we introduce a stainless steel universal crusher

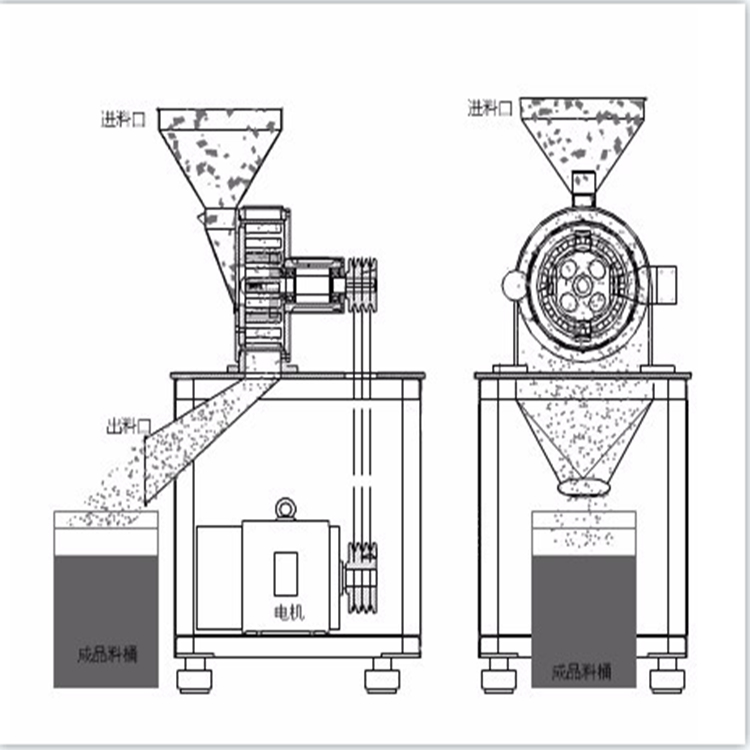

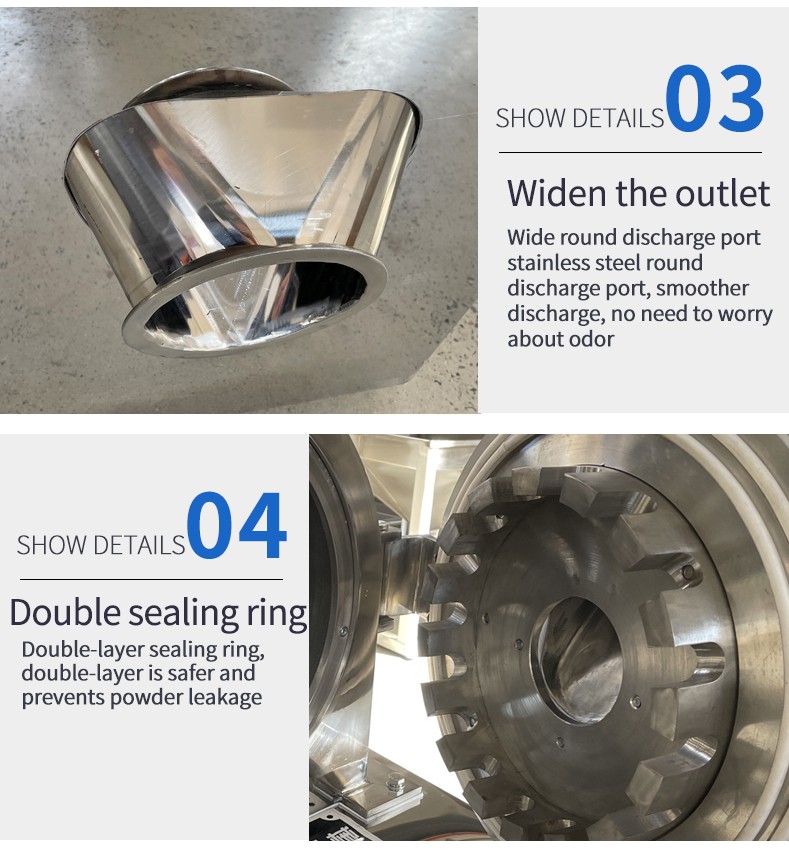

The working principle of the universal crusher is the high-speed relative motion between the movable toothed disc and the fixed toothed disc, which enables the crushed material to be crushed through the combined effects of toothed disc impact, friction, and material impact with each other. The structure of this machine is simple, sturdy, runs smoothly, and has good crushing efficiency. The crushed material can be directly discharged from the grinding chamber of the main machine, and the particle size can be obtained by replacing different aperture mesh screens.

Characteristics of crusher:

1. This machine is made of all stainless steel and meets GMP requirements.

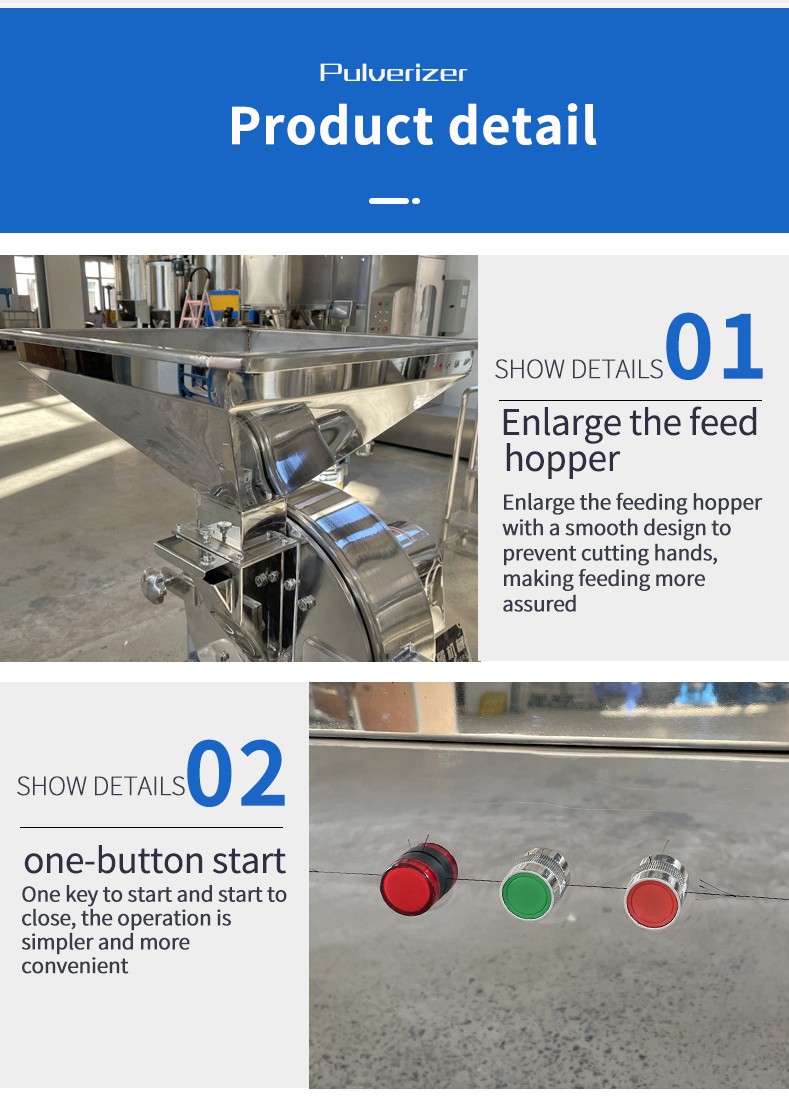

2. The structure is simple, the crushing chamber is easy to assemble and disassemble, and easy to clean.

3. Smooth operation, low noise, and minimal vibration.

4. Easy to operate. Replacing the sieve can control the fineness of the powder.

Precautions for using the crusher:

1. The machine should be placed in a relatively stable place (adjustable feet can be used to adjust the level), and the surrounding environment should be clean, dry, and ventilated.

2. The rotation direction of the motor must be in the direction indicated by the arrow on the casing.

3. Before starting up, it is necessary to check whether there are any impurities in the host chamber. Before crushing the materials, they must be inspected and no impurities are allowed to mix in the materials.

4. Regularly check whether the fixing nuts of the movable gear disc are loose and all fastening components must not be loose. Especially check the screws inside the fixed gear plate.

5. Lubrication: In places where oil cups are installed, appropriate lubricating oil should be injected before starting up. For continuous operation, the number of refills should be increased appropriately. When the actual working hours reach 300 hours, it is necessary to maintain the spindle bearing chamber, clean it, and replace it with new lubricating oil.

6. When replacing vulnerable parts and rolling bearings, pay attention to using the process screw holes, and operate them by a skilled mechanic familiar with the machine. If the user encounters difficulties in operation, they should contact our factory in a timely manner and not dismantle it randomly.