-

11-08 2024

Today, let's talk about which scenarios are suitable for spiral conveyors to work in?

A screw conveyor is a device that relies on a motor to drive the screw to rotate, and materials are carried to a certain height through the rotation of blades. The screw conveyor consists of a main shaft, blades, conveying pipe, motor, hopper, and bracket, and is suitable for conveying granular materials in industries such as food, chemical, plastic, and agriculture.

-

11-05 2024

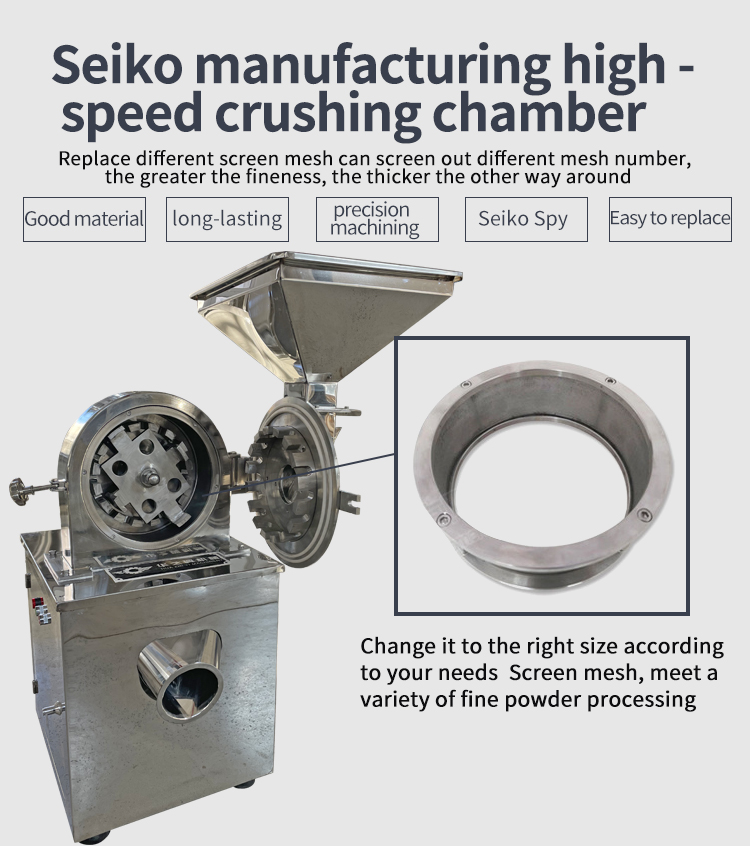

Today, we will introduce a powder grinding machine

The universal crusher has a simple, sturdy structure, smooth operation, and excellent crushing effect. The crushed material can be directly discharged from the grinding chamber of the main machine, and the particle size can be obtained by replacing the mesh screen with different aperture sizes. Universal crushers are suitable for various industries such as agriculture, food, and chemical engineering, and are used to crush multiple varieties, ores, and chemical raw materials.

-

10-28 2024

Today, let's talk about suitable conveyor equipment for packaging and sorting

Belt conveyor, also known as belt conveyor or belt conveyor, is an indispensable economical logistics conveying equipment for forming a rhythmic flow production line. Belt conveyors can be divided into heavy-duty belt conveyors such as mining belt conveyors according to their conveying capacity, while light-duty belt conveyors are mostly used in industries such as electronic plastics, food and light industry, chemical agriculture, and express sorting. Belt conveyors have strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can conveniently implement programmed control and automated operation. The continuous or intermittent movement of conveyor belts is used to transport items weighing less than 100KG or in powder or granular form. It runs at high speed, smoothly, with low noise, and can be transported up and down hills.

-

10-26 2024

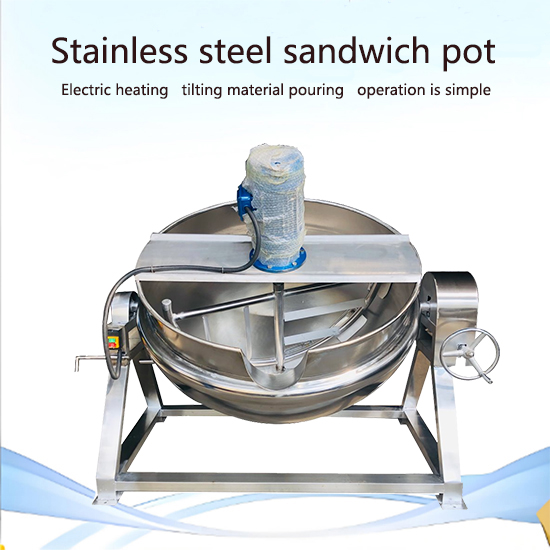

Today, we will introduce a mixing pot for making hot pot ingredients

Sandwich pots are mainly divided into vertical sandwich pots (vertical with stirring sandwich pots) and tilting sandwich pots (tilting with stirring sandwich pots) according to their forms; According to volume, it can be divided into 50 liter sandwich pot, 100 liter sandwich pot, 200 liter sandwich pot, 300 liter sandwich pot, 400 liter sandwich pot, 500 liter sandwich pot, and 600 liter sandwich pot. According to the heating method, it can be divided into steam heating sandwich pot and electric heating sandwich pot. According to the material, it can be divided into all stainless steel sandwich pots and ordinary sandwich pots (sandwich material is A3 steel).

-

10-18 2024

Today we will discuss which materials are suitable for mixing tanks

Mixing tanks, also known as aqueous tanks, are widely used in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research. This equipment can be made of materials such as carbon steel and stainless steel according to the process requirements of the user's product, as well as equipped with heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. This equipment has a reasonable structural design, advanced technology, durability, and features simple operation and convenient use. It is an ideal chemical equipment with low investment, fast production, and high returns.

-

10-09 2024

Today we will introduce the functions of liquid mixing tanks

The mixing tank is suitable for mixing, mixing, blending, homogenizing, and other materials. According to the requirements of the production process, the structure and machine configuration can be standardized and humanized. The mixing tank can achieve feeding, discharging, mixing control, and other manual and automatic control during the mixing process.