Today we will discuss which materials are suitable for mixing tanks

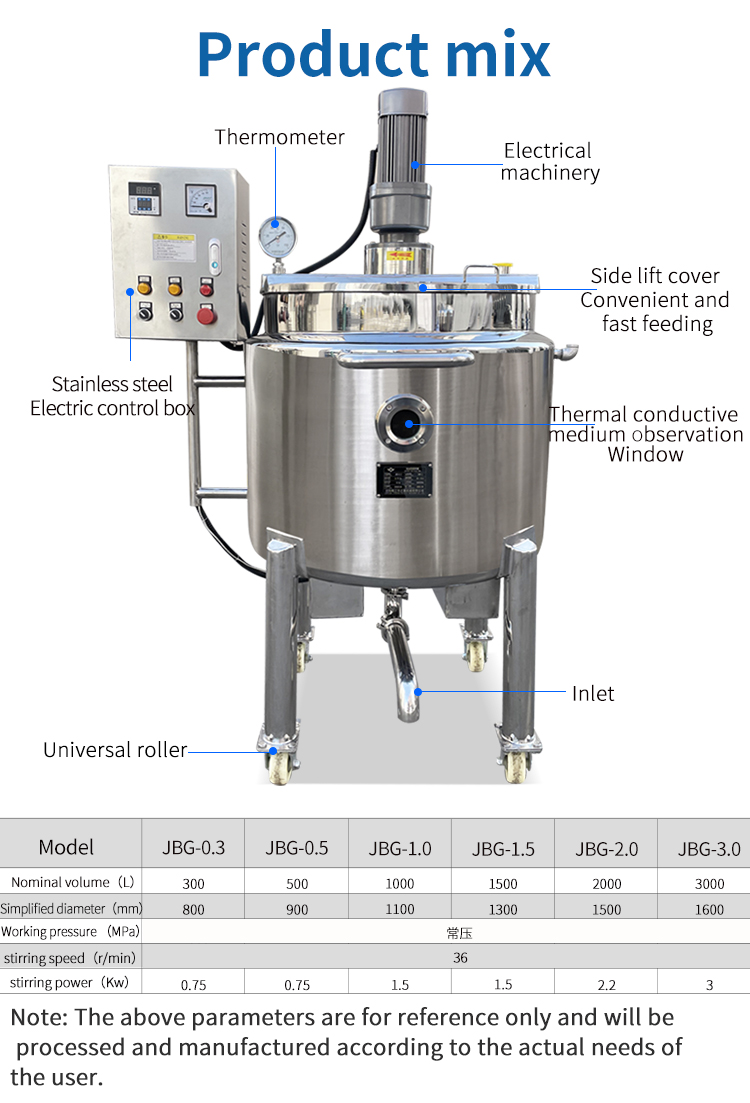

Mixing tanks/reactors are mainly used in industries such as chemical engineering, coatings, pigments, resins, food, building materials, agriculture, scientific research, etc., according to customer production processes and needs. Make a regular or heated version; The equipment has a reasonable structural design, advanced technology, durability, and features simple operation and convenient use.

Introduction to Liquid Mixing Tank:

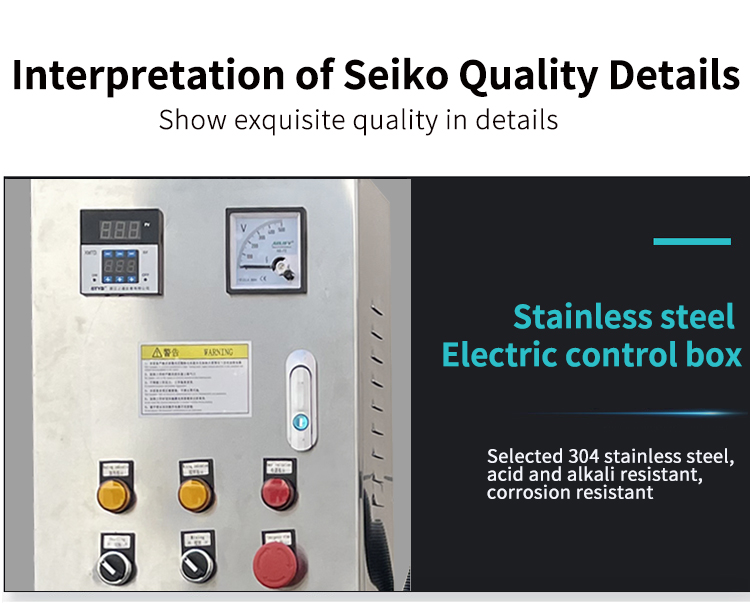

1. Equipment material: SUS304 stainless steel, SUS316L stainless steel, etc.

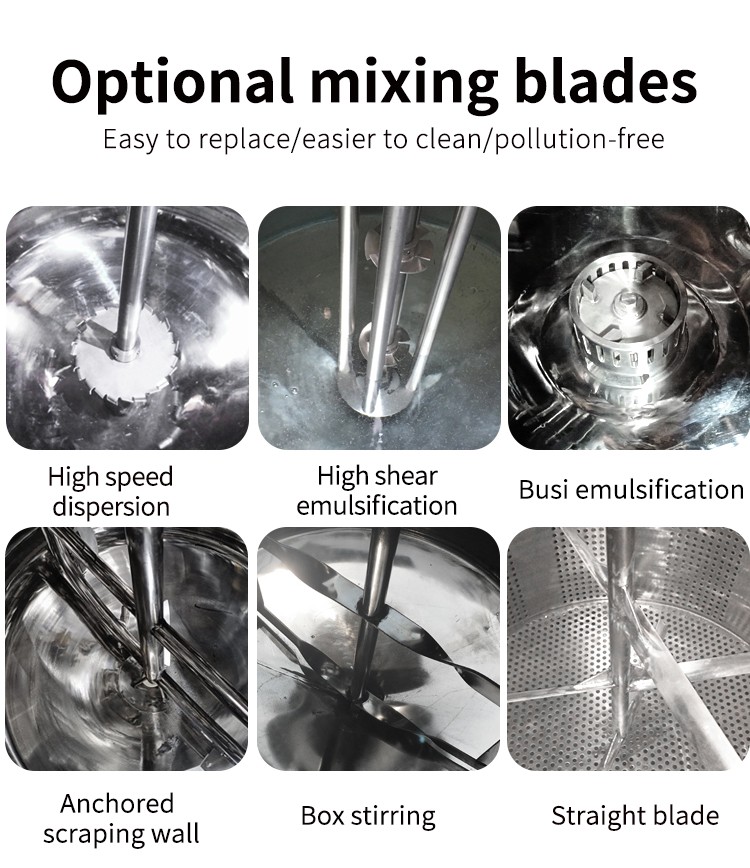

2. Mixing forms: paddle type, anchor paddle type, frame type, spiral belt type, turbine type, dispersed disc type, combination type, etc.

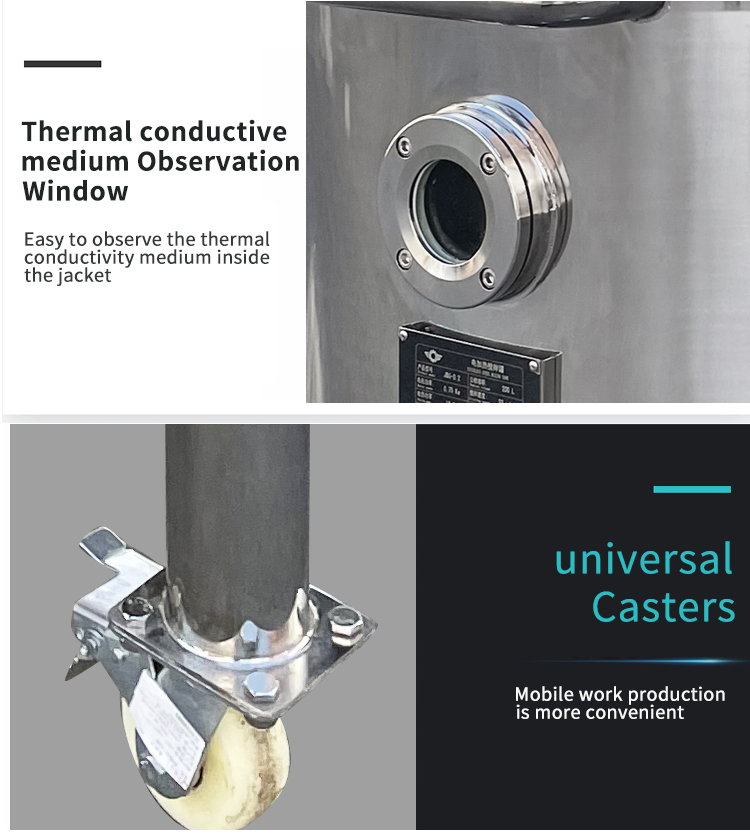

3. Heating method: electric heating, steam heating, water bath heating.

4. Heat transfer medium: heat transfer oil, steam, hot water, electric heating.

5. Heat transfer structure: jacket type, outer coil tube type, inner coil tube type.

6. Equipment structure: upper and lower flat bottoms, upper and lower slants, upper and lower cones, upper and lower heads, etc.

7. The mixing tank can be customized to process 100L-5000L according to customer process requirements.