Today, let's talk about which scenarios are suitable for spiral conveyors to work in?

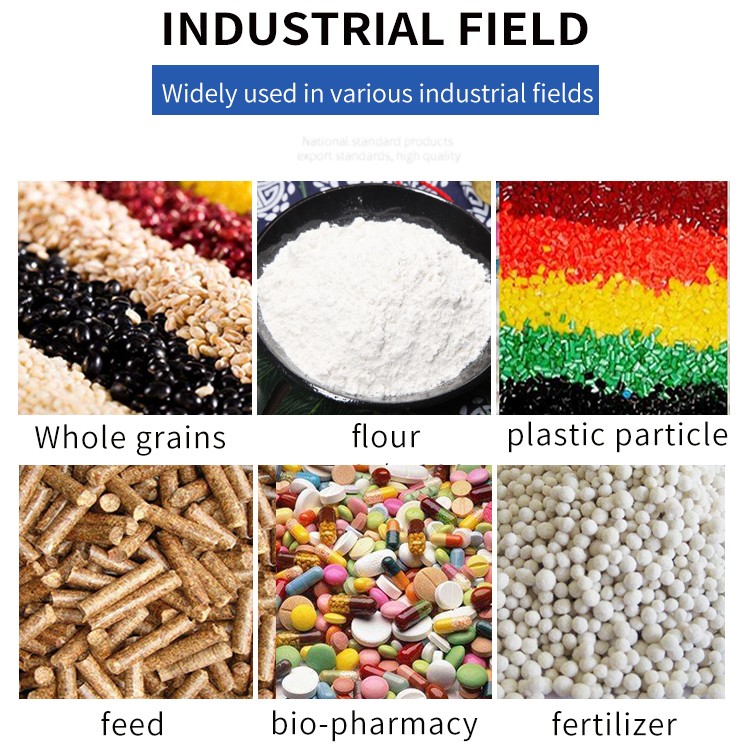

Spiral conveyors are suitable for conveying powdered, granular, and small materials, such as grain, feed, coal powder, cement, clinker, compound fertilizer, grains, rapeseed, and other grain purchasers, as well as feed factories, chemical factories, fertilizer factories, and other conveying materials.

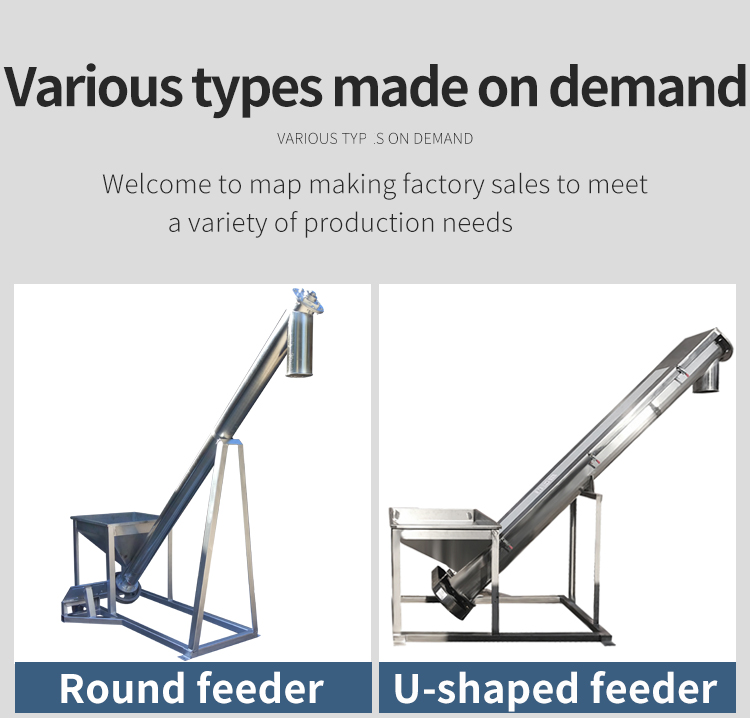

A screw conveyor is a mechanical device that uses an electric motor to drive a screw to rotate and move materials to achieve conveying purposes. Spiral conveyors can transport horizontally, obliquely, or vertically, with advantages such as simple structure, small cross-sectional area, and good sealing. In terms of conveying form, they are divided into axial screw conveyors and non axial screw conveyors, and in terms of appearance, they are divided into U-shaped screw conveyors and tubular screw conveyors.

The characteristics of screw conveyors:

1. It has a large carrying capacity and is safe and reliable.

2. Strong adaptability, easy installation and maintenance, and long service life.

3. The whole machine has a small volume and high rotation speed, ensuring fast and uniform conveying.

4. The whole machine has low noise and flexible arrangement of inlet and outlet.

5. Good sealing performance, the shell is made of seamless steel pipes, and the end flanges are connected to each other as a whole.