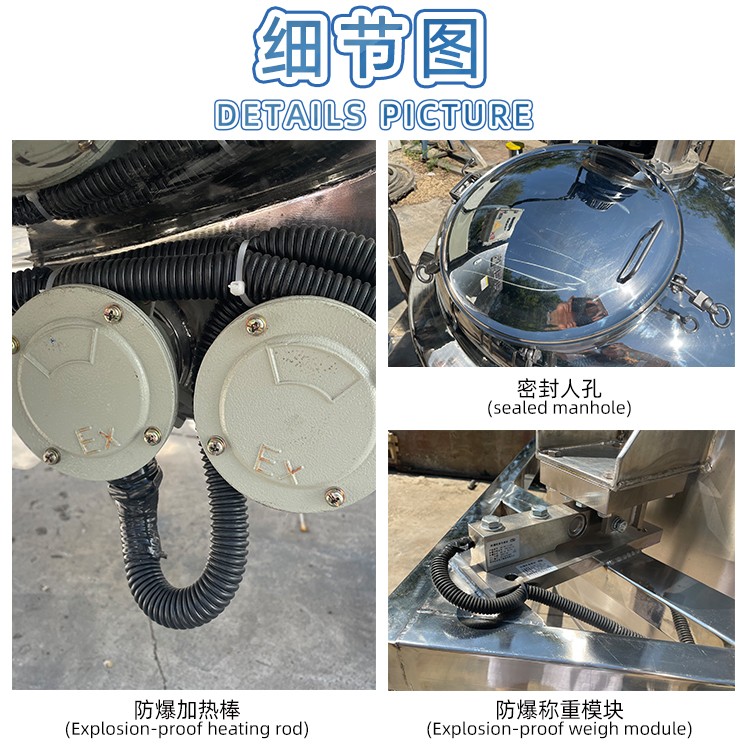

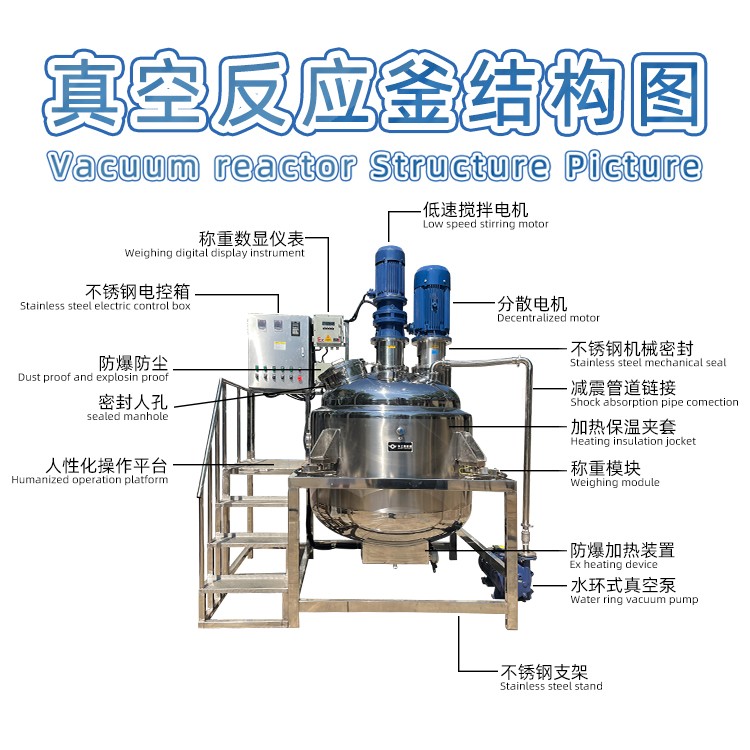

Today we introduce a high shear vacuum reactor

Stainless steel reaction vessels have the characteristics of rapid heating, high temperature resistance, corrosion resistance, hygiene, no environmental pollution, no need for boiler automatic heating, and convenient use. They are widely used in petroleum, chemical, rubber, dyes, food, and other processes such as vulcanization, nitrification, hydrogenation, alkylation, polymerization, and condensation.

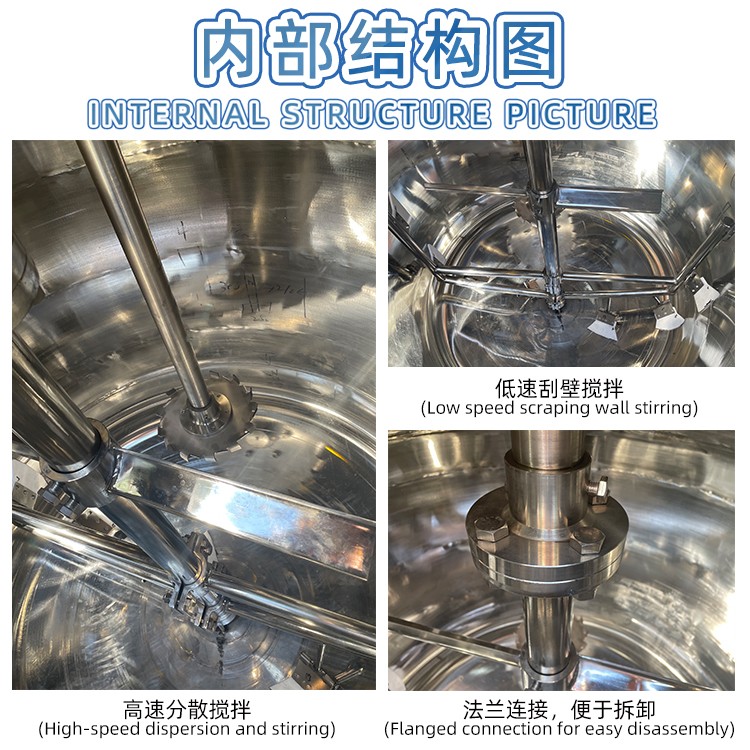

The working principle of a reaction kettle is to add reactants to a reaction vessel, and control the temperature, pressure, and stirring speed during the reaction process through a heating/cooling system and a stirring system, causing the reactants to undergo chemical reactions and ultimately obtain the required products.

Characteristics of stainless steel reaction kettle:

1. Stainless steel material has excellent mechanical properties, can withstand high working pressure, and can also withstand the impact of block solid material feeding.

2. It has excellent corrosion resistance and no rusting phenomenon.

3. Good heat resistance, with a wide working temperature range (-196-600 ℃). It does not oxidize and peel at higher temperatures, so it can be used for direct fire heating.

4. The heat transfer effect is better than that of an enamel reactor, with faster heating and cooling rates.

5. It has good processing performance and can be made into reaction kettles of various shapes and structures according to process requirements. The kettle wall can be polished and polished to prevent hanging of materials and facilitate cleaning.