What is the crushing method of the universal crusher?

It is mainly suitable for the crushing and processing of low to medium hardness materials such as food, medicine, chemical industry, dyes, additives, feed, sawdust, synthetic fibers, and non-metallic minerals. The fineness can be adjusted between 20-120 mesh, and it has the advantages of high yield, fine particle size, low noise, low energy consumption, simple maintenance, and easy installation. It is particularly suitable for the crushing and processing of low to medium hardness materials such as non oily, low viscosity, heat sensitivity, and fibrous materials (such as dendrobium, chili, ginger, cassava chips, peanuts, soybeans, star anise, cinnamon, white sugar, salt crystals, Chinese herbal medicine, grains, tea, cosmetics, pearls, chemical coatings).

Precautions for operation:

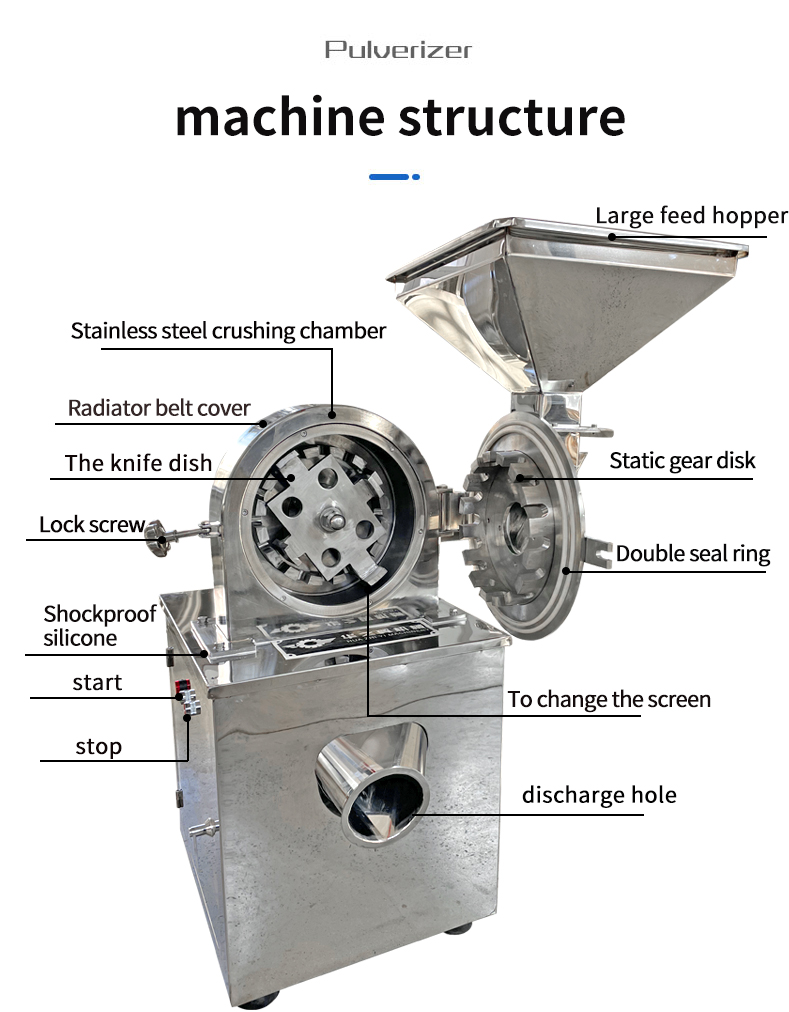

1. Before use, check whether all fasteners of the machine are tightened and whether the belt is tensioned.

2. The direction of spindle operation must conform to the arrow direction indicated on the protective cover, otherwise it will damage the machine and may cause personal injury.

3. Check if the electrical appliances are complete.

4. Check if there are any hard objects such as metal in the crushing room of the machine, otherwise it may damage the cutting tools and affect the operation of the machine.

5. Before crushing, the purity of the material must be checked, and no metal or hard impurities are allowed to mix in, in order to avoid damaging the cutting tool or causing accidents such as combustion.

6. The oil cup on the machine should be regularly filled with lubricating oil to ensure normal operation of the machine.

7. Stop adding materials before stopping the machine. If not in use, remove any remaining debris inside the machine.

8. Regularly check whether the cutting tools and mesh are damaged, and replace them immediately if they are damaged.

9. There may be slight vibrations during use, so be sure to tighten the handle connecting the hood to avoid accidents.