Hello everyone, today we will talk about stainless steel grinding machines

Colloidal mill is a machine that grinds and crushes fluid materials, mainly consisting of a shell, stator, and rotor. The regulating mechanism, cooling mechanism and motor are widely used in many industries, such as peanut paste, soybean milk, dairy products, dairy products, vegetables, peppers, mung beans, yams, carrots, bone mud, asphalt and other fluid materials grinding.

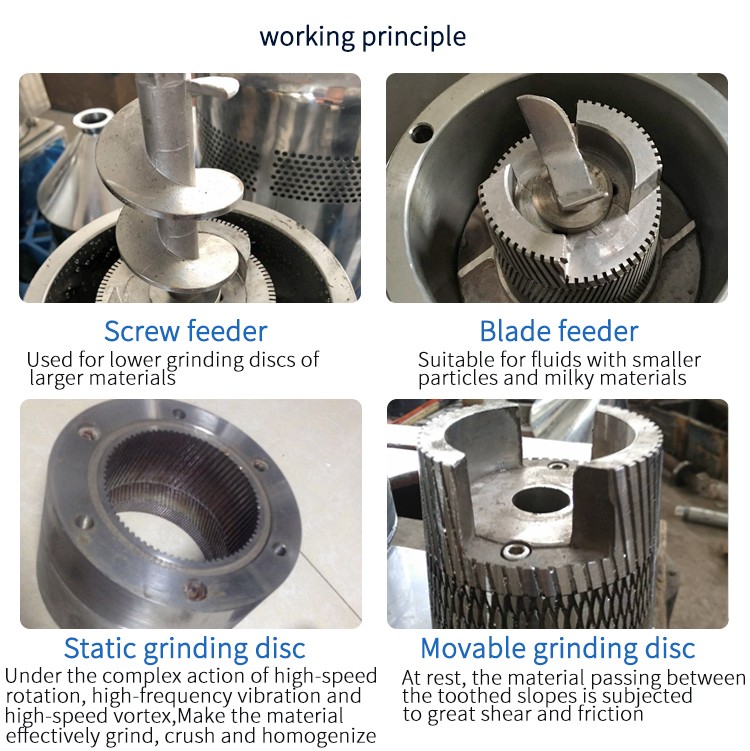

The colloid mill is composed of stainless steel and semi stainless steel colloid mills. The basic principle of the colloid mill is that the fluid or semi fluid material passes through the high-speed relative movement between the fixed and moving teeth, causing the material to be subjected to strong shear force, friction force, and high-frequency vibration, effectively being crushed, emulsified, homogenized, and heated, thereby obtaining satisfactory precision processed products.

A pair of conical rotating teeth and fixed teeth in a colloid mill move relative to each other. The material is crushed, emulsified, homogenized, and subjected to shear force, friction force, centrifugal force, and high-frequency vibration through the gap between the fixed and rotating teeth.

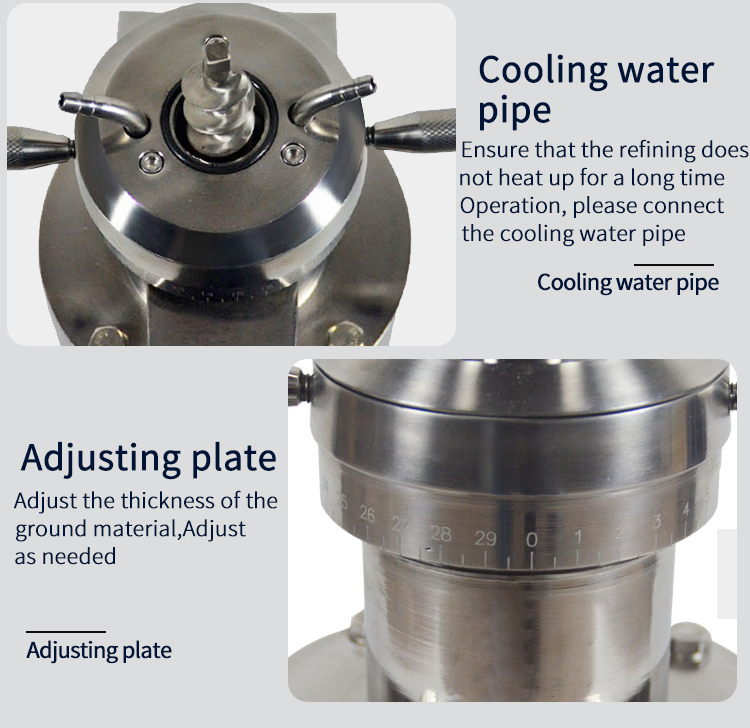

Advantages of colloid mill: Compared with pressure homogenizers, colloid mills are first and foremost centrifugal equipment. Their advantages are simple structure, convenient equipment maintenance, and suitability for materials with higher viscosity and larger particles. Its main drawback is also determined by its structure. Firstly, due to centrifugal motion, the flow rate is not constant and varies greatly for materials of different viscosities. For example, the same equipment can have a flow rate difference of more than 10 times when handling viscous paint materials and thin dairy fluids; Secondly, due to the high-speed friction between the stator and the material, a large amount of heat is easily generated, causing the processed material to denature; Thirdly, the surface is prone to wear, and after wear, the refinement effect will significantly decrease.

Introduction to colloid mill:

1. The material is made of either whole machine stainless steel or material contact surface stainless steel, which is not easy to corrode and has a beautiful appearance.

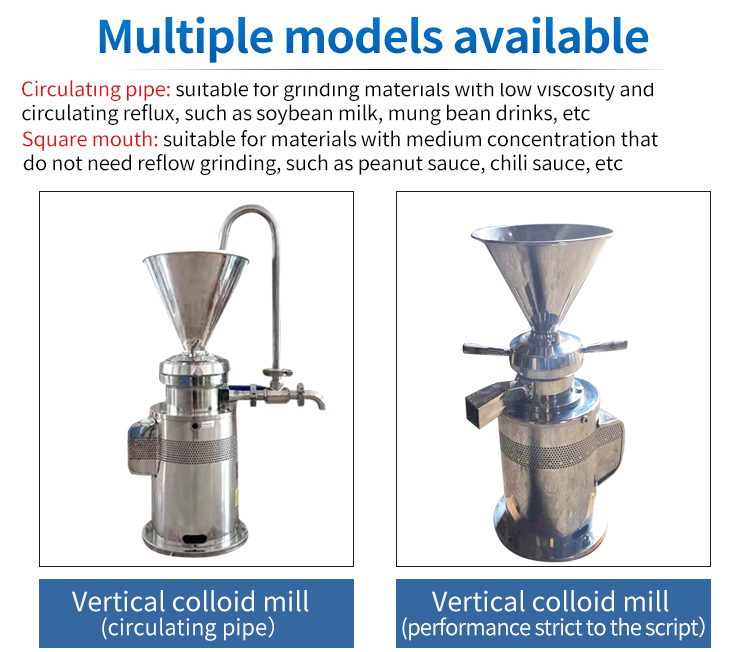

2. Colloidal mills are structurally divided into two types: vertical and horizontal.

3. The product design has a compact structure, stable operating performance, low energy consumption, and good sealing.

4. Simple operation, high production efficiency, and strong adaptability.

5. It can be made according to customer requirements and supports customization.

Colloidal grinding is made of stainless steel or plate stainless steel and is commonly used in industries such as food and chemical industry. Its principle is to rotate the fixed and rotating teeth at high speed, and the processed material generates downward spiral impact force through its own weight or external pressure (which can be generated by the pump). When passing through the gap between the fixed and rotating teeth (adjustable gap), it is subjected to strong physical effects such as shear force, friction force, and high-frequency vibration, Effectively emulsify, disperse, and crush materials.