Hello, today we will talk about stainless steel grinding machines

Colloidal grinding is suitable for homogenizing, emulsifying, mixing, and crushing various semi fluids, fluids, emulsions, and emulsions of sesame paste, peanut butter, tomato paste, chili paste, filling bean paste, lotus seed paste, egg yolk, jujube paste, bone paste, semi solid materials, emulsified asphalt, paint coatings, and other semi fluids.

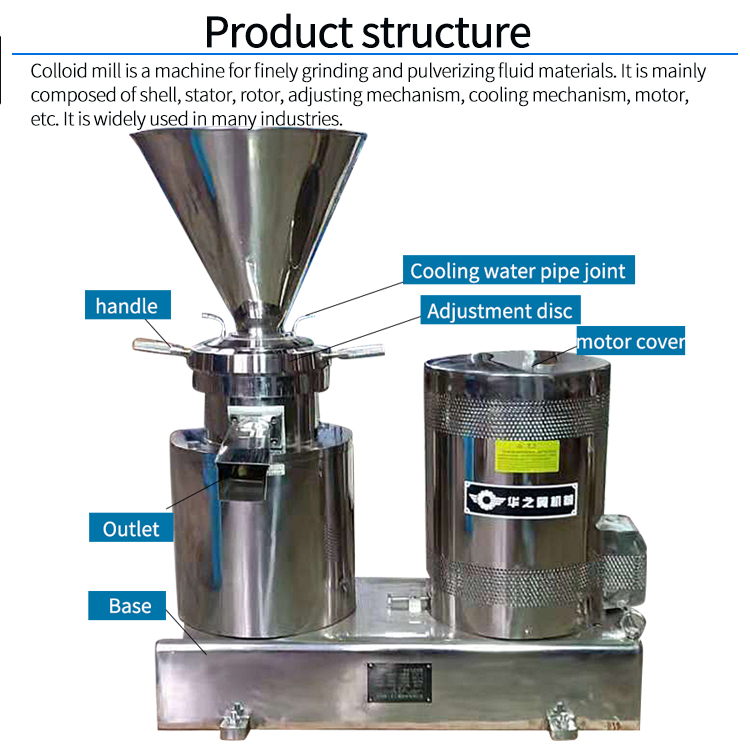

The structural characteristics of the colloid mill include two specifications: vertical and horizontal. The main unit is composed of a housing, stator, rotor, regulating mechanism, cooling mechanism, motor, etc. Its main components are made of stainless steel, which is corrosion-resistant and non-toxic. The user can choose different specifications and models of colloid mills according to the characteristics of different materials, production efficiency, and different purposes, in order to achieve good results.

Colloid mill discharge port:

1. The circulating pipe is suitable for materials with low viscosity that need circulating reflux grinding, such as soybean milk, fruit and vegetable juice, drinks, etc.

2. The square mouth is suitable for materials with medium to high concentrations that do not require reflux grinding, such as peanut sauce, chili sauce, meat paste, etc

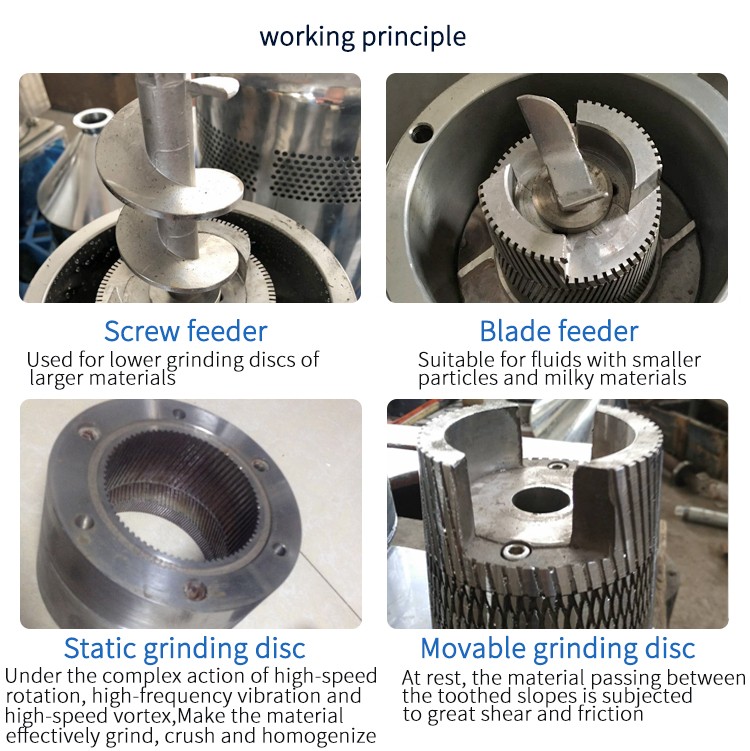

The colloid mill achieves the effect of material crushing and emulsification through the relative motion between the high-speed rotating shear blade and the fixed grinding disc, utilizing shear force, collision force, and friction force. Colloid mill is a commonly used equipment for crushing and emulsifying materials. Its main working principle is to cut and grind materials into fine particles or even lotion through the relative movement between high-speed rotating shear knife and fixed grinding plate. Colloidal mill utilizes shear force, collision force, and friction force to disperse and uniformly mix materials, and achieve fine particle size crushing effect. Among them, the material enters the grinding chamber through the feeding port, passes through the continuous action of the high-speed rotating shear blade and grinding disc, and is finally discharged through the discharging port.

Operation method of colloid mill:

1. Check the appearance of the colloid mill to see if there are any deformation, obvious scratches or residual defects on the funnel, circulation pipe, motor, and base of the colloid mill.

2. Connect the funnel, circulation pipe, discharge port, etc. of the colloid mill and check for any loose or loose connections.

3. Adjust the clearance between the grinding discs of the colloid mill, rotate the dial of the colloid mill by hand, and check if the dial can adjust the fineness of the grinding head normally.

4. Start the colloid mill, use water as the medium, and test the machine to see if the colloid mill can operate normally.

5. Open the discharge valve and discharge the water from the discharge port for debugging.