Today we will talk about stainless steel grinding machines

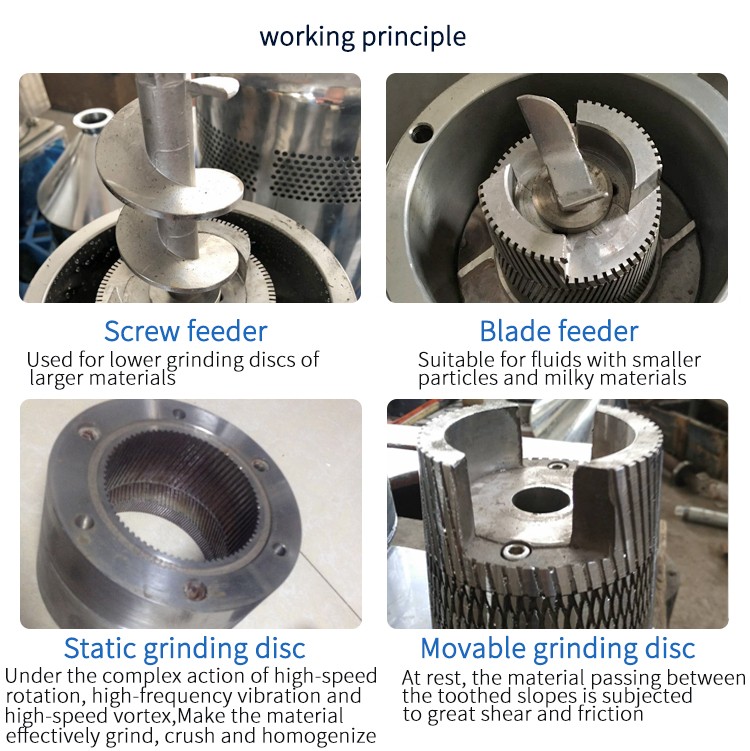

Colloid mill is a semi-wet material processing equipment, mainly composed of grinding head, base and motor.Colloid mill of dynamic and static grinding discs and mechanical seals in the core part of the machine is the key part of the colloid mill.

Colloidal mills are widely used in various fields such as food industry and daily chemical industry. In the food industry, the colloid mill is often used to grind bone, peanut butter, pepper sauce, garlic paste, ginger paste, sesame paste, walnut jam, rice milk, soybean milk, bean paste, fruits and vegetables, beverages and other materials; Commonly used in the chemical industry for grinding asphalt, cosmetics, toothpaste, salt solutions, catalysts, etc.

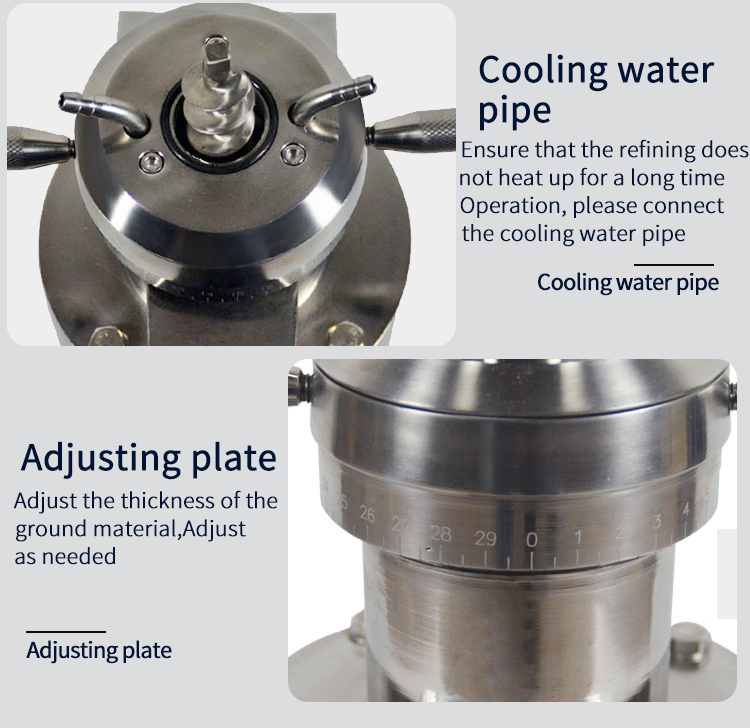

The structural characteristics of the colloid mill include two specifications: vertical and horizontal. The main unit is composed of a housing, stator, rotor, regulating mechanism, cooling mechanism, motor, etc. Its main components are made of stainless steel, which is corrosion-resistant and non-toxic. The user can choose different specifications and models of colloid mills according to the characteristics of different materials, production efficiency, and different purposes, in order to achieve good results.

Electric food grade high-speed colloid mill

The structure design of the colloid mill is compact, easy to operate, well sealed, and has stable performance. The key components such as the dynamic and static grinding discs are made of high-strength stainless steel, which has good corrosion resistance and wear resistance, ensuring that the materials are pollution-free, hygienic and pure. In addition, there are various models of colloid mills, such as vertical, horizontal, and split type, which are suitable for production needs of different scales.

Operation method of colloid mill:

1. Check the appearance of the colloid mill to see if there are any deformation, obvious scratches or residual defects on the funnel, circulation pipe, motor, and base of the colloid mill.

2. Connect the funnel, circulation pipe, discharge port, etc. of the colloid mill and check for any loose or loose connections.

3. Adjust the clearance between the grinding discs of the colloid mill, rotate the dial of the colloid mill by hand, and check if the dial can adjust the fineness of the grinding head normally.

4. Start the colloid mill, use water as the medium, and test the machine to see if the colloid mill can operate normally.

5. Open the discharge valve and discharge the water from the discharge port for debugging.