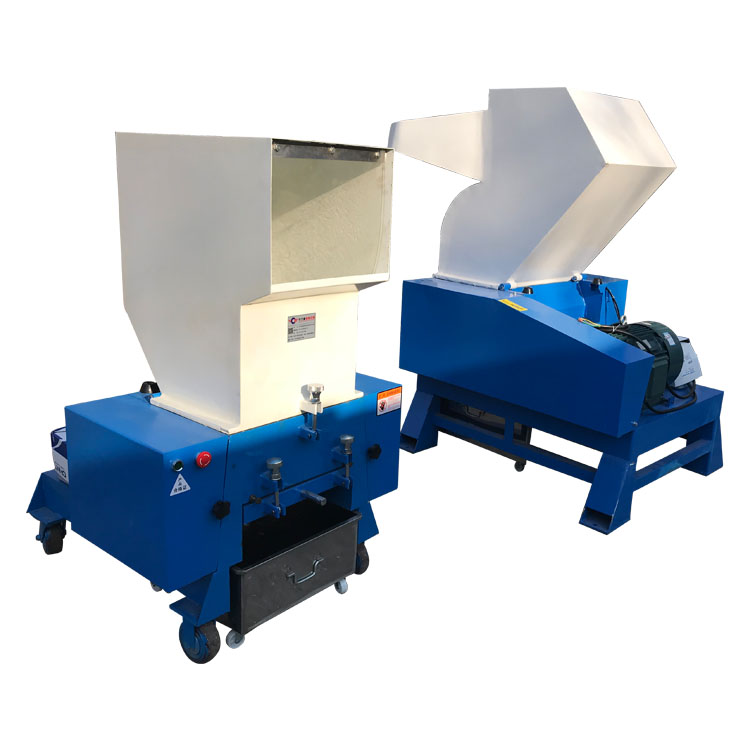

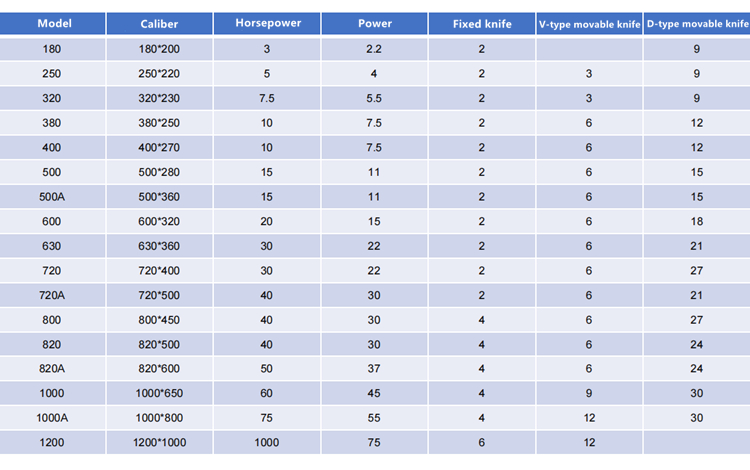

Recycling Plastic Crusher Machine

Brand Huazhiyi

Product origin China

Delivery time 15 days

Supply capacity 1000 pcs

Plastic shredder and crusher plastic bags crusher crushing plastic crusher machine for sale

Feature:

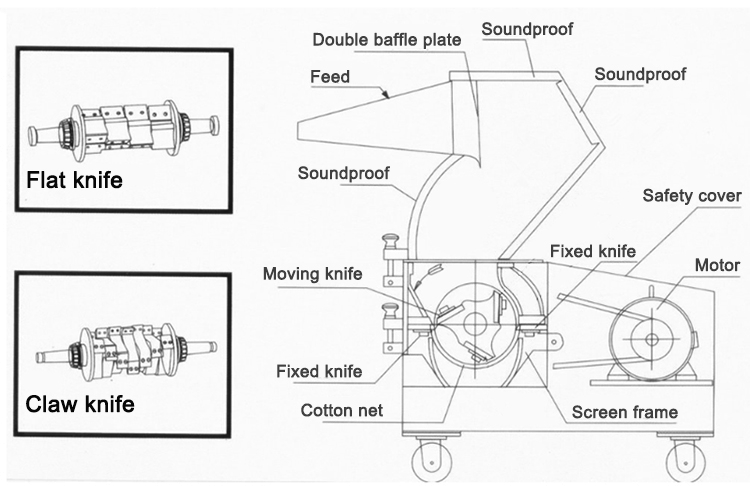

1. This upgraded design is aimed at cutting bottles and barrels. The rotary blades and stationary blades are settled as a V-shaped angle. This angle can make better cutting. The granules are evenly cut and less powder is caused.

2. The chamber is made of harder steel. It’s wear-resisting and easy for maintenance.

Download

Product Description

Recycling Plastic Crusher Machine Plastic shredder and crusher plastic bags crusher crushing plastic crusher machine, which makes the pumping rotation keep good for a long time, the knife type design is reasonable, the product is evenly granulated, the knife seat is heat-shrinked, and the shape design is beautiful and generous.

The large width of the blade cutter is suitable for crushing large volume thin wall and thin material products, improving crushing efficiency, with electronically controlled safety design, motor with overload protection device and power chain protection system, which makes the equipment have good safety and Environmentally friendly. Power saving and durable.

Easy operation, easy and quick tool change, the tool holder is optimized. The claw knife can disperse the force, which makes the shearing force of each piece increase. It is suitable for crushing thick materials, hard blocks, material heads, etc., which effectively improves the cutting force of the tool. Reduce tool wear.

Product Structure

Overhaul of plastic crusher

The main wear parts of the plastic crusher are the movable knife blade, the fixed knife blade, the rotating shaft journal and the bearing, the blade tightening bolt and the screen.

The small repair cycle of the plastic crusher depends on the service life and the degree of wear of the blade. Replacing the blades, grinding worn blades, and adjusting the gap of the mouth are all minor repairs. The time interval is generally half a month.

Intermediate repair work is carried out every six months to a year, including blade replacement, bearing replacement, inspection of rotating shafts, screens, and transmission system maintenance.

Large-scale repair work is carried out every one to two years, replacing the rotor with the blade installed, overhauling the housing of the studio, and overhauling the transmission system.

Application And Crushing Effect Show

1. Q:Are you a manufacturer or trading company?

A: We are a manufacturer.

2. Q: Where is your factory?

A: Our factory is located in Shenyang, the capital of Liaoning Province in the north of China.

3. Q :How about the quality of your products?

A: Our sales team will ask you for details about your need,and then our professional designer will give you the most appropriate production flowing map,and after your agree,our workshop will begin producing according to the drawing strictly.

4. Q: Do you Provide the technical service oversea?

A: Yes.We can provide technical service oversea.

We will send professional workers to help customers oversea if you need.

5. Q: About spare parts?

A: We provide some necessary spare parts for free, and we can suggest client to buy some spare parts for back up.

6. Q: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Sales Manager: Amanda Sun

E-mail: Amanda@huazhiyijx.com

Tel: +0086 024 67768608/67768609

Mob: +0086 18842507772

Whatsapp: +0086 18842507772

Wechat: +0086 18842507772

Address: Door 3, No. 77-37, 13th Road, Shenyang Economic And Technological Development Zone,

Shenyang City, Liaoning Province, China