Plastic Shredder Crusher Grinder Machine

Brand Huazhiyi

Product origin China

Delivery time 15 days

Supply capacity 1000 pcs

Recycling Shredder Plastic Bottle Crushing Machine Plastic Crusher

1. Universal plastic pulverizer adopts sealed pumping, which makes the pumping rotation keep good for a long time, the knife type design is reasonable, the product is evenly granulated, the knife seat is heat-shrinked, and the shape design is beautiful and generous.

2. The large width of the blade cutter is suitable for crushing large volume thin wall and thin material products, improving crushing efficiency, with electronically controlled safety design, motor with overload protection device and power chain protection system, which makes the equipment have good safety and Environmentally friendly. Power saving and durable.

3. It is suitable for crushing and reusing various plastics, especially for all kinds of hard plastics (such as material heads, shoe materials, etc.).

4. Easy operation, easy and quick tool change, the tool holder is optimized. The claw knife can disperse the force, which makes the shearing force of each piece increase. It is suitable for crushing thick materials, hard blocks, material heads, etc., which effectively improves the cutting force of the tool. Reduce tool wear.

Download

Product Description

1. The Film & Bottle Crushing Machine has been specially design for the processing of flms,bottles, and other hollow thin walled plastics. It has a centrally hinged two-piece cutting chamber with a robust welded steel construction, with the upper and lower sections of the housing meeting horizontally. Reversible stator knives with double cutting edges are fitted as single elements to the lower section of the housing, allowing multiple re- sharpening and adjustment of the stator knives. There is a hinged screen cradle and hinged door for easy screen access.

2. The rotor is a heavy duty paddle type design with knife cover plates to protect the blades when processing abrasive applications. The knife mounting bolts are screwed into the mounting plates as opposed to the rotor. All knives are manufactured from chrome nickel tool steel as standard, but when processing applications that are particularly abrasive the AGF granulators can be ftted with a specially designed wear resistant rotor utilizing wear resistant steel parts and hardox facing.

3. The v-cut cutting geometry offers distinct advantages over other rotor designs, including higher throughput with reduced power consumption, better quality cut, and lower noise levels. The AGF rotor configuration provides between 20-40% additional throughput in comparison to standard rotor configurations.

4. Specially designed knife setting jig means that the knives can be adjusted from outside the machine, significantly reducing the downtime required to change/set knives.

5. The base frame has a solid welded construction with anti-vibration rubber feet to reduce vibration and noise.' The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. Integrated suction trough for material discharge.

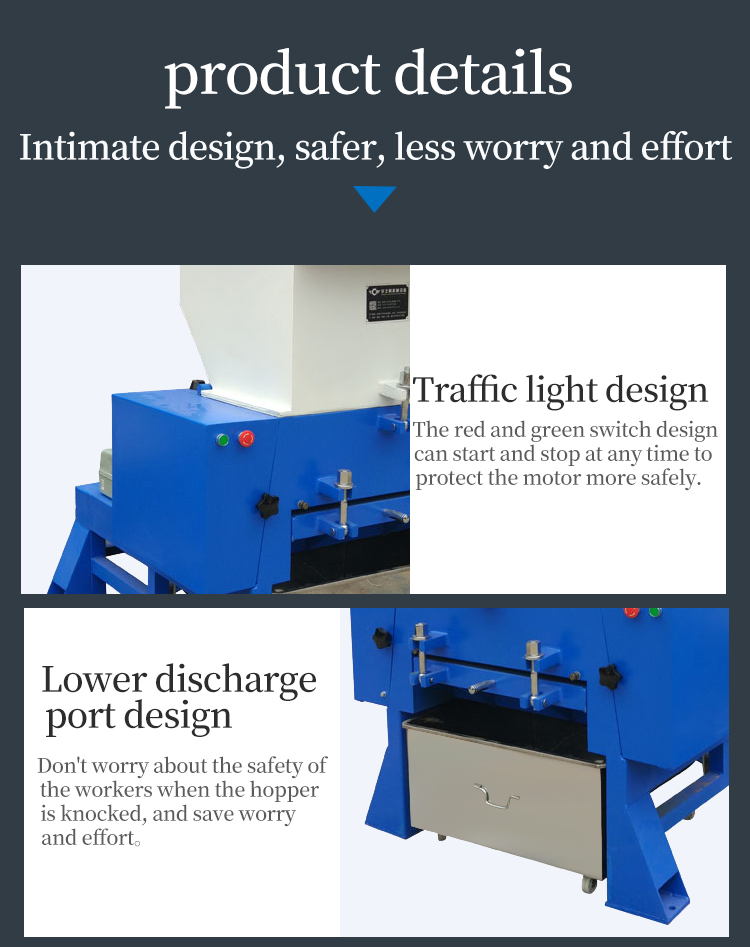

6. Specially designed hopper with 3 sets of curtains to prevent material flybacks. Integrated rundown safety device prevents access to the rotor until it has come to a complete stop. A safety switch prevent machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.Product Structure

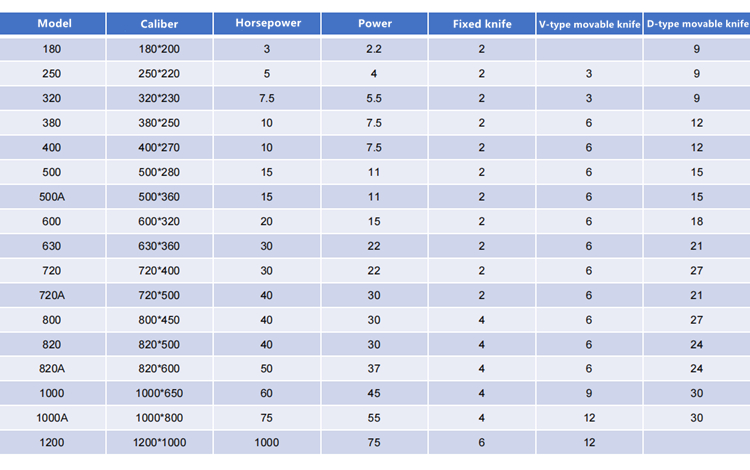

Product Parameter

Packaging and Shipping

1. Q:Are you a manufacturer or trading company?

A: We are a manufacturer.

2. Q: Where is your factory?

A: Our factory is located in Shenyang, the capital of Liaoning Province in the north of China.

3. Q :How about the quality of your products?

A: Our sales team will ask you for details about your need,and then our professional designer will give you the most appropriate production flowing map,and after your agree,our workshop will begin producing according to the drawing strictly.

4. Q: Do you Provide the technical service oversea?

A: Yes.We can provide technical service oversea.

We will send professional workers to help customers oversea if you need.

5. Q: About spare parts?

A: We provide some necessary spare parts for free, and we can suggest client to buy some spare parts for back up.

6. Q: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Sales Manager: Amanda Sun

E-mail: Amanda@huazhiyijx.com

Tel: +0086 024 67768608/67768609

Mob: +0086 18842507772

Whatsapp: +0086 18842507772

Wechat: +0086 18842507772

Address: Door 3, No. 77-37, 13th Road, Shenyang Economic And Technological Development Zone,

Shenyang City, Liaoning Province, China