-

08-15 2023

Completion of new product for stainless steel feeding machine

-

08-12 2023

Double layer stainless steel electric heating reactor ready for shipment to the Philippines

-

07-27 2023

Explosion-proof IBC agitator ton drum mixer suitable for which industries

Explosion-proof IBC ton drum mixers suitable for which industries? Commonly used in the chemical industry.

-

06-21 2023

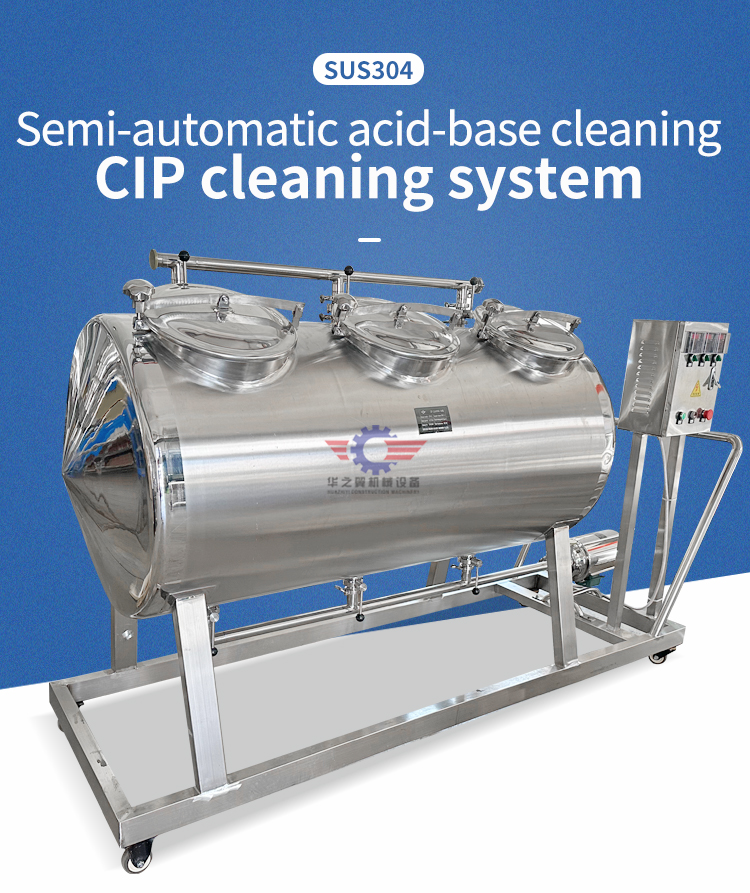

CIP clean tank Acid and alkali cleaning of reactor mixing tank

CIP cleaning tank is specially designed for acid and alkali cleaning of reaction kettle and mixing tank of chemical plant, food factory, pharmaceutical factory and other enterprises.

-

07-21 2023

Laundry powder mixers do this cost-effective

Laundry powder mixer is a powder mixer for daily chemical plants.

-

03-07 2023

High cost performance support customized stainless steel horizontal mixer

This horizontal mixer has high mixing degree and less residue, which is suitable for mixing organic fertilizer and inorganic fertilizer. The specific characteristics are: the materials are fully mixed, thus improving the mixing uniformity. The use of a novel rotor structure allows the clearance between the rotor and the casing to be adjusted to close to zero, effectively reducing the residual amount of materials. The special rotor design of the machine can also crush large materials. The overall structure is more reasonable, the appearance is beautiful, and the operation and maintenance are convenient.