High cost performance support customized stainless steel horizontal mixer

stainless steel horizontal mixer

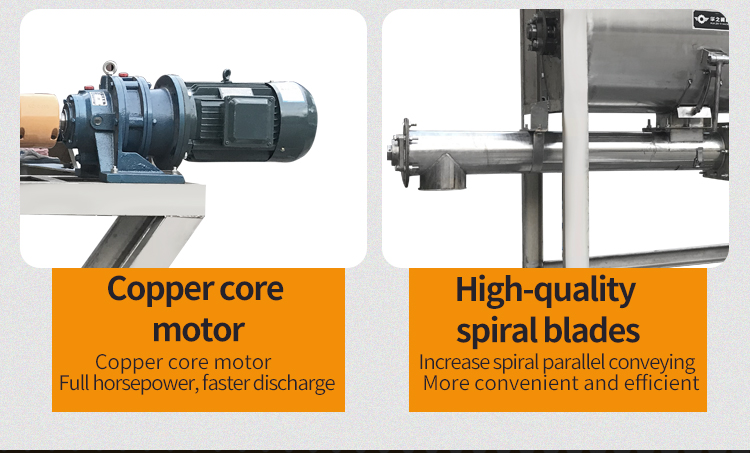

The horizontal mixer is under the action of the inner and outer spiral belts on the mixing shaft to turn the material within the scope of the cylinder. The inner spiral belt pushes the material from the middle to the two sides, the outer spiral belt pushes the material from both sides to the center, and the back and forth mixing material moves along the radial direction and changes under the rotation of the spiral belt, thus forming a convection cycle. The stirring of the above movement, the materials are quickly and uniformly mixed in a very short period of time, the shaft seals at both ends are specially sealed, the powder and liquid have no leakage, the replacement cost of the sealing consumables is low, and the replacement is convenient, so it is a widely used, adaptable High-efficiency mixing equipment with strong performance and good effect.

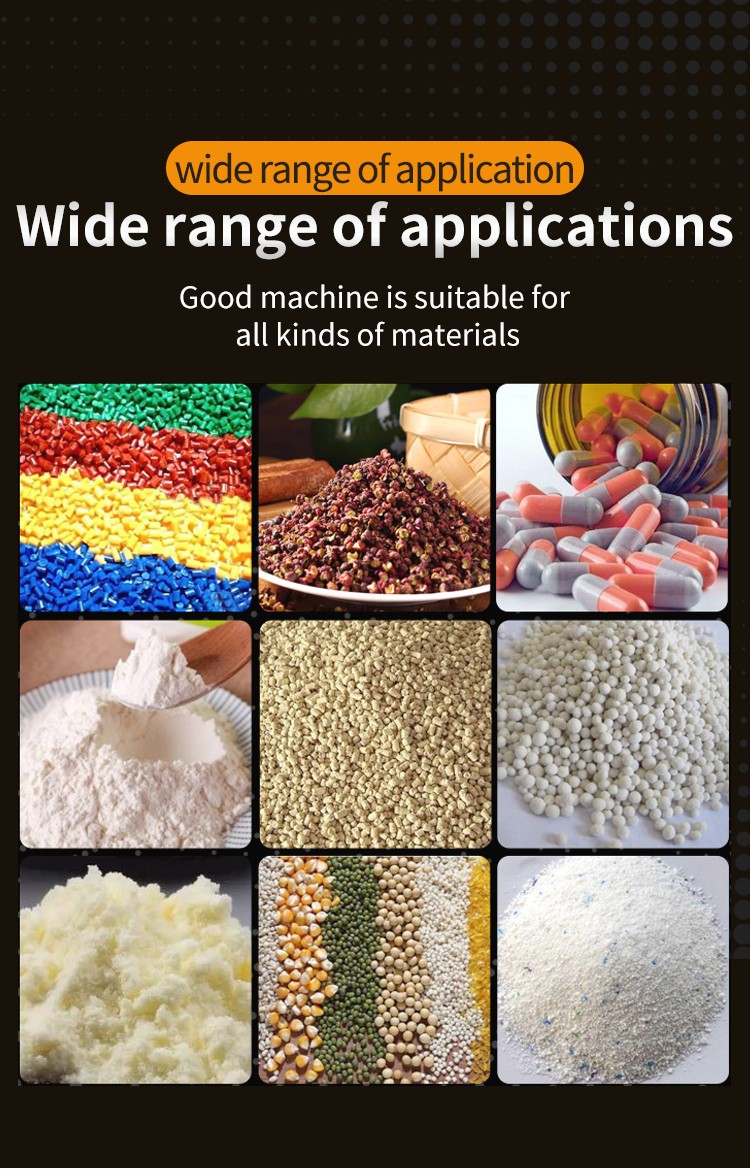

It can evenly mix salt, feed, grain and other powdery or granular materials, and has the characteristics of high efficiency, good mixing quality, short unloading time and less residue.

Widely used in quartz sand powder, starch, rubber, dry powder of additives, putty, medicine, food, chemicals, ceramic powder, milk powder, soybean powder, chemical industry, compound fertilizer, health care products, dyes, pigments, rubber, building materials, rare earth, Mixing of plastic glass and new materials, nuclear energy materials, refractory materials, etc. (ie powder and liquid) and solid slurry (ie powder and glue), especially suitable for mixing viscous materials. Material mixing, has good adaptability, biological, medical food and other industries, it is recommended to use stainless steel material, mixing dry powder sand slurry containing vitrified microbeads, it is recommended to use horizontal ribbon mixing.