food factory chemical factory stainless quantitative steel filling machine

Brand HUAZHIYI

Product origin CHINA

Delivery time 15DAY

Supply capacity 100

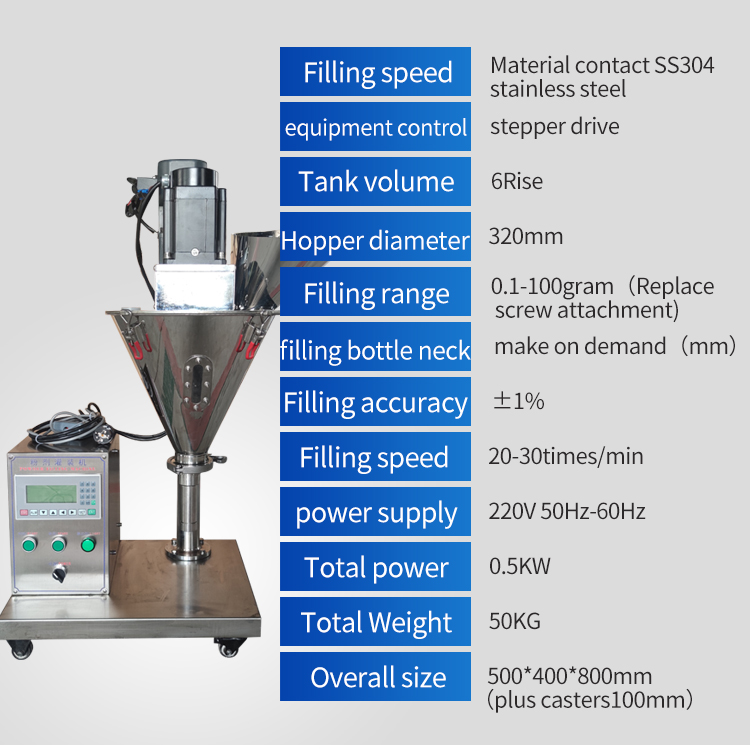

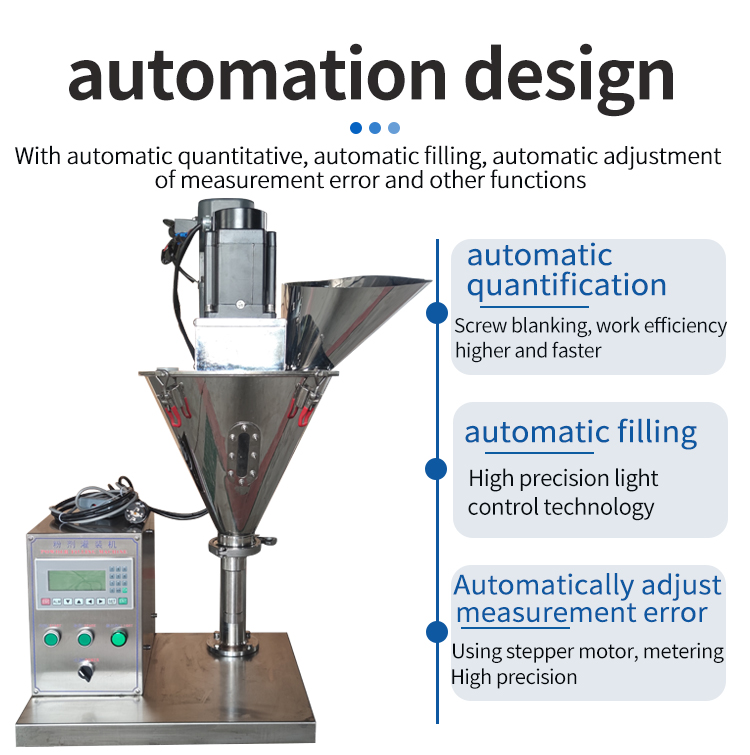

This machine integrates machine, light, electricity and instrument. It is controlled by single chip microcomputer and has the functions of automatic quantification, automatic filling and automatic adjustment of measurement error. It is fast and has high measurement accuracy, and the measurement method can be set according to the packaging volume.

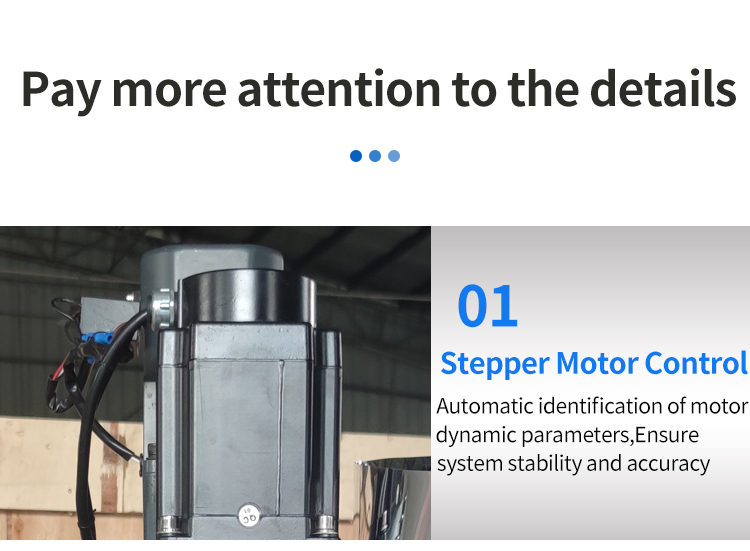

1. Adopt stepper motor to control cutting, low noise and long service life.

2. The hopper is made of 304 stainless steel, and the material opening is enlarged to facilitate the delivery of materials.

3. The hopper and filling head are provided with buckles, which are convenient for disassembly and cleaning.

4. PLC control system, Chinese and English bilingual display screen, easy to operate.

5. The screw is measured and unloaded, the filling head can be customized according to the size of the bottle mouth, the filling volume is different, and the screw size can be changed.

6. The screw is easy to disassemble and assemble, with internal stirring to avoid material accumulation and unloading.

7. The machine can be set to automatically cut the material, or press the foot switch to cut the material. Press the foot pedal once to select the material once.

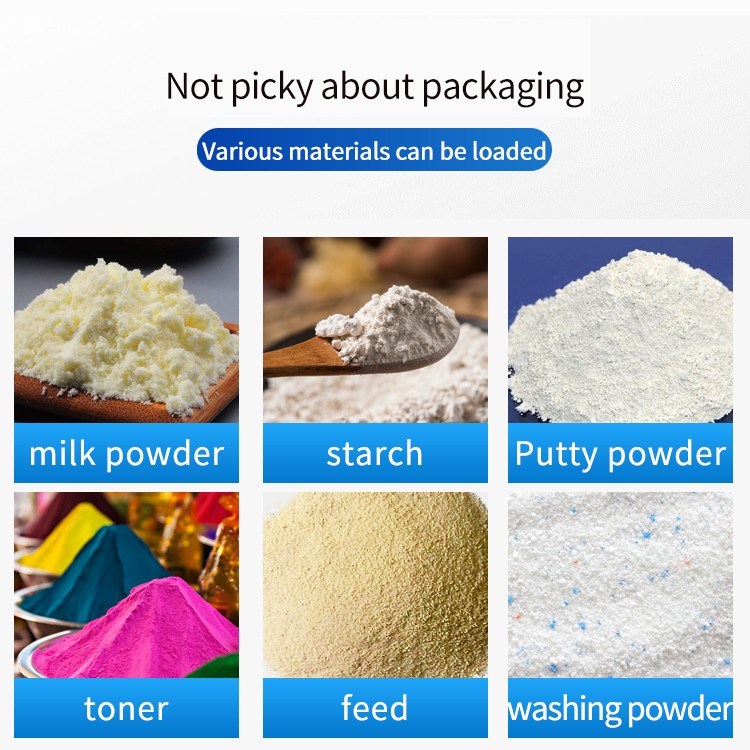

Small-dose powder filling machine is a packaging equipment that automatically quantifies, fills and adjusts the measurement error, and is mostly used in the food industry. Chemical industry, pharmaceutical industry, daily chemical industry, etc., suitable for quantitative packaging of milk powder, starch, pesticides, veterinary drugs, premixes, additives, seasonings, ginger powder, loose powder, tooth powder, silver powder, iron powder, etc.

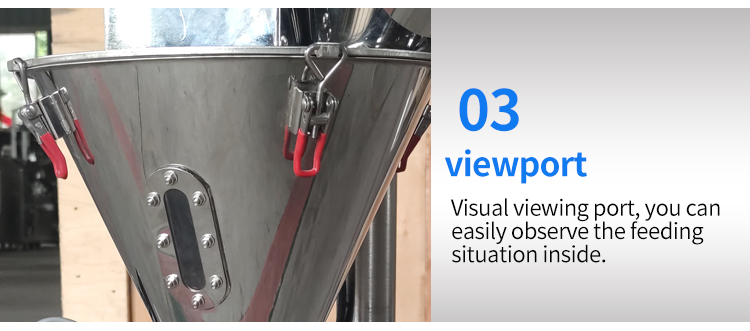

Details of powder packaging machine:

1. Adopt stepper motor to control cutting, low noise and long service life.

2. The hopper is made of 304 stainless steel, and the material opening is enlarged to facilitate the delivery of materials.

3. The hopper and filling head are provided with buckles, which are convenient for disassembly and cleaning.

4. PLC control system, Chinese and English bilingual display screen, easy to operate.

5. The screw is measured and unloaded, the filling head can be customized according to the size of the bottle mouth, the filling volume is different, and the screw size can be changed.

6. The screw is easy to disassemble and assemble, with internal stirring to avoid material accumulation and unloading.

7. The machine can be set to automatically cut the material, or press the foot switch to cut the material. Press the foot pedal once to select the material once.

Working principle of powder packaging machine: This machine integrates machine, light, electricity and instrument. It is controlled by single chip microcomputer and has the functions of automatic quantitative, automatic filling, automatic adjustment of measurement error, etc. It adopts screw feeding, stepping motor light control technology, photoelectric Switch-controlled blanking, fast speed, high measurement accuracy, and the measurement method can be set according to the packaging volume.

A: Yes, we have 100% tested before delivery....more