Working principle of stainless steel horizontal mixer

Working principle of stainless steel horizontal mixer

Application field:

Widely used in chemical, plastic, rubber, food, medicine, macromolecule, construction, fireproof materials and other particles, powder, liquid materials stirring and mixing.

working principle:

Double-layer spiral blades are arranged on the drive shaft of the horizontal mixer. The outer blades transport the material to the middle, and the inner blades transport the material to the outer side. Under the convective movement of the double-layer spiral belt, the material forms a low-power and high-efficiency mixing environment. The material in the barrel is driven by the inner and outer diameter screws installed on the stirring shaft, so that the agitator can turn the material in a wide range in the barrel. When the stirring device is working, the inner screw drives the material near the axis to rotate, and the axial direction is pushed from the inside to both sides. The mixed materials can be uniformly mixed in a relatively short time.

Performance parameters:

1. The horizontal plastic mixer is made of different types of stainless steel such as carbon steel, SUS201, SUS304, SUS316L, etc. The whole machine can also be made of stainless steel according to customer requirements;

2. Multiple models of mixing capacity can be selected from 200-10000L capacity specifications, which can be customized by customers;

3: The interior of the barrel is polished and smooth, the blades are stirred without dead ends, and each batch can be mixed evenly in 5-10 minutes;

4. All-stainless steel central shaft and single or double "S" shaped paddles, mix materials quickly and evenly;

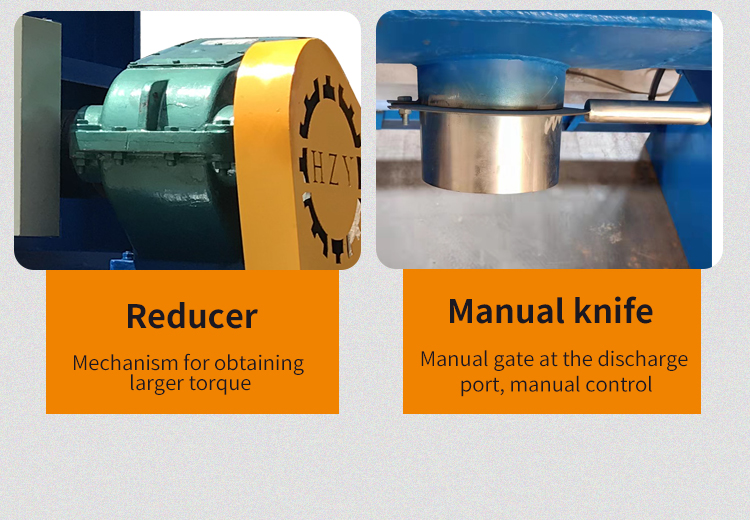

5: The discharge port has a turn knife type, a wall type, a valve, manual, automatic (pneumatic, electric) waterproof, dust-proof and no leakage.

6. The motor adopts 100% copper wire motor. Cycloidal pinwheel reducer, long life, low noise; or cylindrical gear reducer, large torque. The transmission parts are linked by industrial V-belts, and the replacement of accessories is convenient and quick.

Horizontal heating mixer:

Add an interlayer on the basis of the outer wall of the original horizontal mixer, inject heat-conducting oil into the interlayer, and use a heating rod for electric heating, the temperature is controllable, and the oil temperature is preset. °The heating system works, and the heating is stopped. If the oil temperature is lower than 150°, the heating system will start to ensure that the temperature of the heating system is constant and stable, and the material drying and heating effect is good. This is how a stainless steel horizontal mixer works