What raw materials can stainless steel colloid mill grind?

The stainless steel colloid mill is a grinder for grinding materials. Stainless steel colloid mill is through shearing, grinding and high-speed stirring. Grinding relies on the relative motion of two tooth surfaces, one of which is rotating at high speed and the other is stationary, so that the material passing between the tooth surfaces is subjected to great shearing force and friction force, and at the same time, it vibrates at high frequency, high-speed vortex, etc. Under the action of complex force, the material can be effectively dispersed, incubated, crushed and homogenized.

The stainless steel colloid mill is a grinder for grinding materials. Stainless steel colloid mill is through shearing, grinding and high-speed stirring. Grinding relies on the relative motion of two tooth surfaces, one of which is rotating at high speed and the other is stationary, so that the material passing between the tooth surfaces is subjected to great shearing force and friction force, and at the same time, it vibrates at high frequency, high-speed vortex, etc. Under the action of complex force, the material can be effectively dispersed, incubated, crushed and homogenized.

Stainless steel colloid mills can be used in many industries such as the food industry: dairy products, chocolate, bean paste, jam, peanut butter, cream drinks, etc. Chemical industry: pigments, lubricants, spices, dyes, emulsified asphalt, emulsified rubber, catalysts, paint coatings, etc. Pharmaceutical industry: cod liver oil, confidentiality, fitness cream, queen bee, pollen, etc. Daily chemicals: shoe polish, toothpaste, cosmetics, balsam, soap, detergent, etc. Other industries: construction industry, paper industry, plastic industry, battery industry, etc. Having said so much, do you now know which raw materials can be ground by a stainless steel colloid mill?

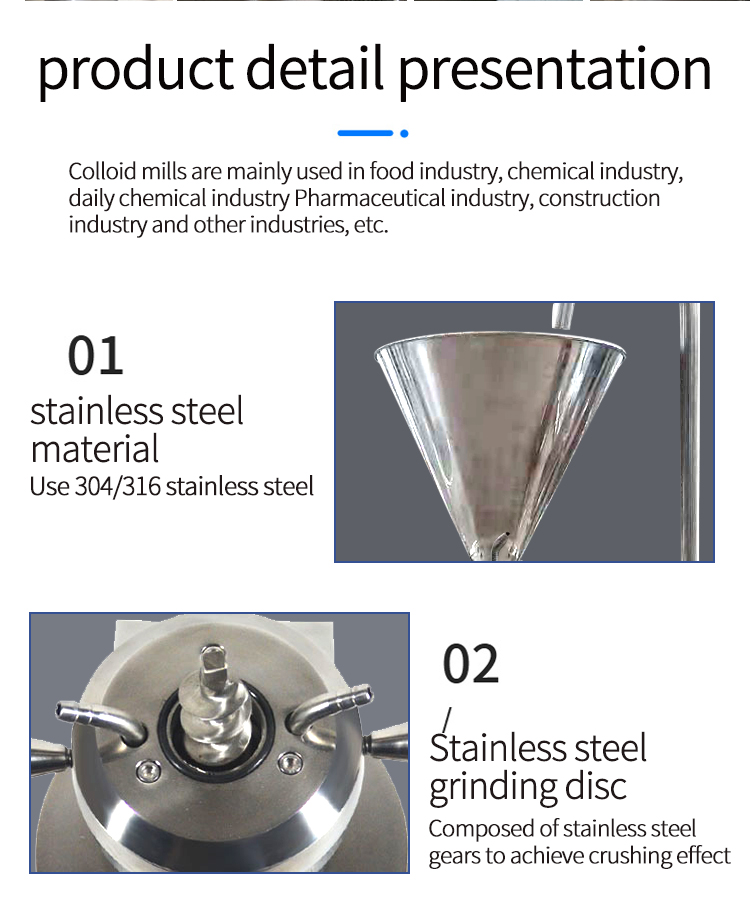

Stainless steel colloid mill is made of stainless steel, which is strong and durable, does not rust, does not oxidize, and will not have chemical reactions to raw materials. So the service life is long. And cleaning is also easier.