What brand is a good colloid mill and how to choose a colloid mill manufacturer

What brand is a good colloid mill and how to choose a colloid mill manufacturer

The jam and toothpaste products we often consume in our daily lives are processed by manufacturers through colloidal mills, which are also the main processing machinery for many fluids, such as semi fluid homogenization, emulsification, and crushing. So how should we find a colloid mill manufacturer? What brand is a good colloid mill?

How to choose a colloid mill manufacturer

How to choose a colloid mill manufacturer

In fact, before choosing a colloid mill manufacturer, we need to understand what kind of colloid mill machinery is a good one. Firstly, a colloid mill is a centrifugal processing machine that uses an internal motor to drive the difference in dynamic and static speed between the rotor and stator. The rotor is rotated to shear, grind, homogenize, and emulsify the material, resulting in products that are finely crushed and uniformly emulsified after processing.

Colloid mill manufacturer

A good colloid grinding machine itself is made of sanitary grade stainless steel material, especially the parts that come into contact with the material. Its material needs special processing, and it needs to have certain wear resistance and corrosion resistance, especially the grinding disc, which is the rotor and stator. Because colloid mills are used in the pharmaceutical, chemical, and food industries, for the chemical industry, some of the materials that need to be processed have some corrosiveness, so it is necessary for the interior of the colloid mill to also have certain corrosion resistance characteristics. This is also true in the pharmaceutical industry, and some semi fluid materials need to be processed and ground into powder, so they also need to have certain wear resistance characteristics for the body itself.

If you need to learn more about the characteristics of colloid mills, you can focus on what are the characteristics of colloid mills, what are the characteristics of colloid mills, and what are the characteristics of colloid mills

Characteristics of vertical colloid mill

Due to the prominent characteristics of colloid mill machinery, we need to understand the relevant mechanical characteristics when selecting colloid mill brands and manufacturers. There are also different specifications and models of colloid mills according to different industries and material characteristics. When selecting colloid mills, we need to compare them with the operating speed of the colloid mill based on the required flow rate and output ratio of industry materials, Choosing the appropriate machine model and specifications for the industry is the correct way to choose a colloid mill manufacturer.

What brand is a good colloid mill

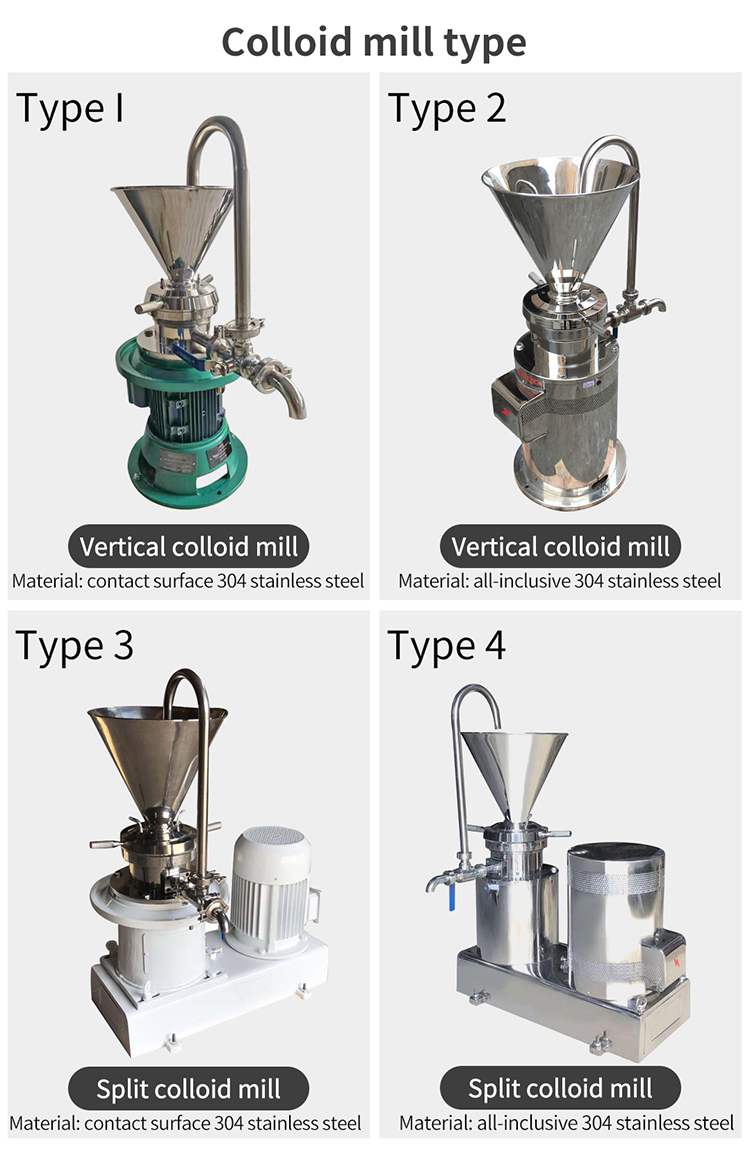

When choosing a colloid mill brand, we need to use European style colloid mills, vertical colloid mills, or split type colloid mills based on industry demand, material demand, and production efficiency. We can also judge whether the colloid mill machinery is durable based on its material.

Split type colloid mill and vertical colloid mill

The production efficiency of the machine body can also be judged based on its relevant parameters, and it should be mentioned here that since the colloid mill is an equipment that adjusts the gap between its internal rotor and stator based on the particle size of the material for processing, its flow rate is not constant. Therefore, if there are significant differences in the thinness and viscosity of different materials, there will also be differences in the flow rate processed by the colloid mill, This requires customers to pay special attention when choosing the brand and manufacturer of the colloid mill.

The above is an introduction to what brands are good for colloid mills and how to find colloid mill manufacturers. For more knowledge about colloid mills, you can follow Huazhiyi colloid mill factory.