Vertical double screw conical mixer vertical batch mixers

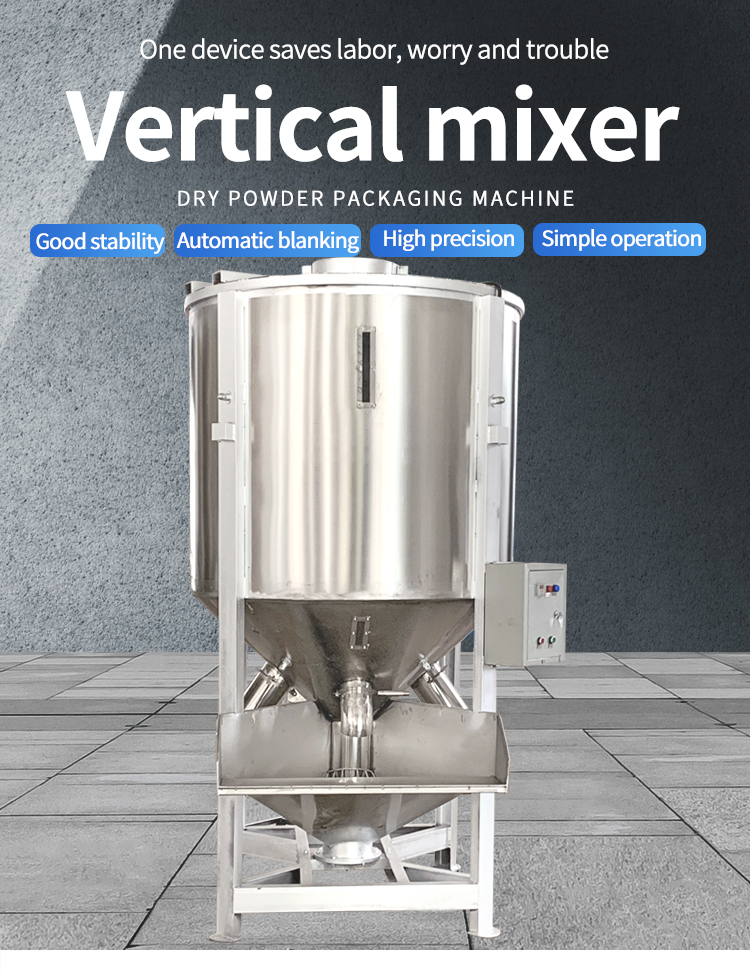

Granules vertical conical mixer vertical batch mixers are mainly composed of: motor wheel, motor, barrel, screw, discharge port, cleaning port, belt pulley, window, human ladder, entrance, electrical box, and loop blanking port , Feeding port and other components.

The vertical plastic pellets mixing machine, vertical concrete mixer, vertical screw feed mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then fly them in an umbrella shape and return to the bottom, so that the raw materials are stirred up and down in the barrel, and a large amount can be mixed in a short time.

The vertical plastic pellets mixing machine, vertical concrete mixer, vertical screw feed mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then fly them in an umbrella shape and return to the bottom, so that the raw materials are stirred up and down in the barrel, and a large amount can be mixed in a short time.

Granules vertical conical mixer vertical batch mixers are mainly composed of: motor wheel, motor, barrel, screw, discharge port, cleaning port, belt pulley, window, human ladder, entrance, electrical box, and loop blanking port , Feeding port and other components.

The vertical plastic pellets mixing machine, vertical concrete mixer, vertical screw feed mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then fly them in an umbrella shape and return to the bottom, so that the raw materials are stirred up and down in the barrel, and a large amount can be mixed in a short time.

The vertical plastic pellets mixing machine, vertical concrete mixer, vertical screw feed mixer is the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then fly them in an umbrella shape and return to the bottom, so that the raw materials are stirred up and down in the barrel, and a large amount can be mixed in a short time.