Vegetable dehydration machine centrifugal dehydrator centrifuge separator

Industrial dehydrator manufacturing process:

The large-capacity dehydrator is manufactured according to international standards, and its control part adopts imported frequency conversion speed control. Equipped with a reasonable in and out of the cloth device. It is the first in China, with large capacity, low energy consumption and perfect shockproof, timing, automatic and safety control system.

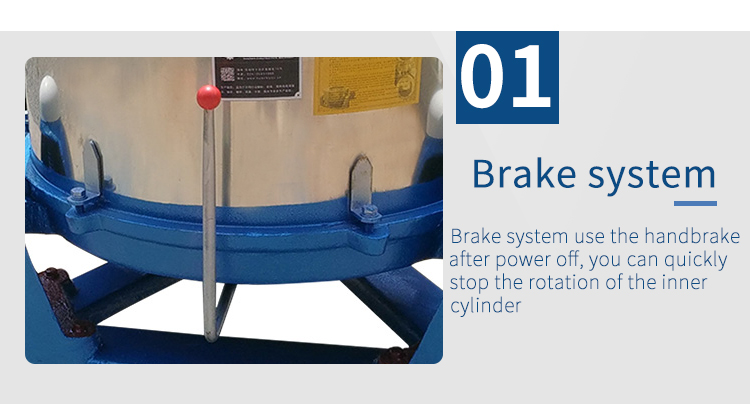

The frequency conversion centrifugal dehydrator is composed of triangular chassis, cast feet, garden chassis, rotating drum, shell, motor and so on. The drum and shell are made of high-quality stainless steel. Driven by triangular belt, the frequency conversion control motor drives the starting wheel, so that the machine starts slowly and reaches the design speed to ensure the smooth running of the machine. There is a braking device in the machine, which has good braking performance and can make the machine stop running in a short time.

Centrifugal dehydrators can be divided into: under-drain dehydrators, top-down dehydrators, stationary centrifugal dehydrators and mobile dehydrators. Mainly used for dehydration and spinning of various textiles (needles), clothing, printing and dyeing, food, hardware, chemical raw materials, and latex products after washing. Widely used in textile, printing and dyeing, clothing, hotels, hospitals, chemicals, food, hardware, machinery parts, latex products and other enterprises and institutions. It is industrially suitable for grinding, cutting, oil washing, cooling and dewatering (oil) of various metal parts. It is suitable for drying, dehydration and degreasing of hardware, electronic parts, iron filings, aluminum filings and copper filings. And electroplating and grinding factories, hardware lathe factories, hardware fastener factories and other factories.

Structural features

1. Industrial centrifugal dehydrators are all three-legged suspension structures, which can avoid foundation vibration caused by unbalanced loads in the transferred soybeans during operation.

2. The inner cylinder and outer shell of the industrial centrifugal dehydrator are made of stainless steel, and the transfer soy sauce is made of stainless steel. The cage seat and the chassis are made of cast iron, and the water outlet pipe is under the chassis.

3. The main shaft is made of high-quality steel through heat treatment and finishing.

4. The transmission part adopts V-belt drive, and the centrifugal starting wheel is directly driven by the motor, which can make the machine start slowly and gradually reach the design speed to ensure the smooth operation of the machine.

5. There is a brake opening and closing arm in the machine, which has good braking performance and can make the machine stop quickly.