The difference between stainless steel colloid mill and homogenizer and grinder

Stainless steel colloid mill is a processing machine for grinding, pulverizing, shearing and emulsification of specific materials. When it comes to stainless steel colloid mills, we have to say that they are similar to homogenizers and grinders. These three often make people There is an illusion that they are the same type of processing machinery, but in fact their focus is different.

The difference between colloid mill and homogenizer

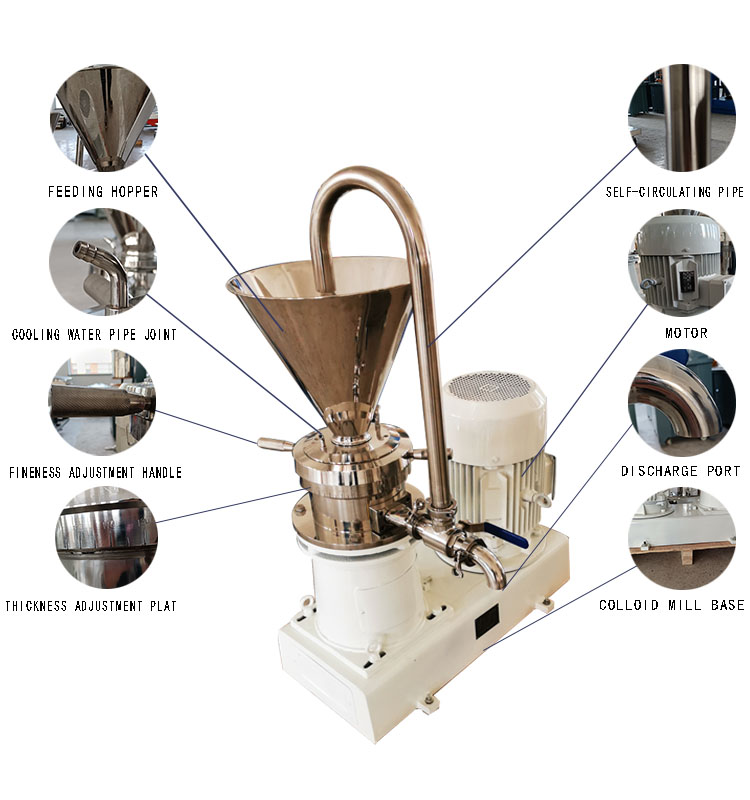

Among them, one of the biggest features of the stainless steel colloid mill is its ultra-fine crushing ability. The internal motor drives the colloid mill to move the static grinding body to crush the materials for many times, so that the materials can achieve the effect of ultra-fine crushing. certain homogenization. The homogenizer uses the high-speed shearing ability of the extrusion and internal blades to process the material multiple times. This is the main feature of the homogenizer.

The difference between a stainless steel colloid mill and a homogenizer is also reflected in that one is for the purpose of crushing materials, and the other is for the purpose of homogenization of materials. This is their difference.

The difference between a colloid mill and a grinder

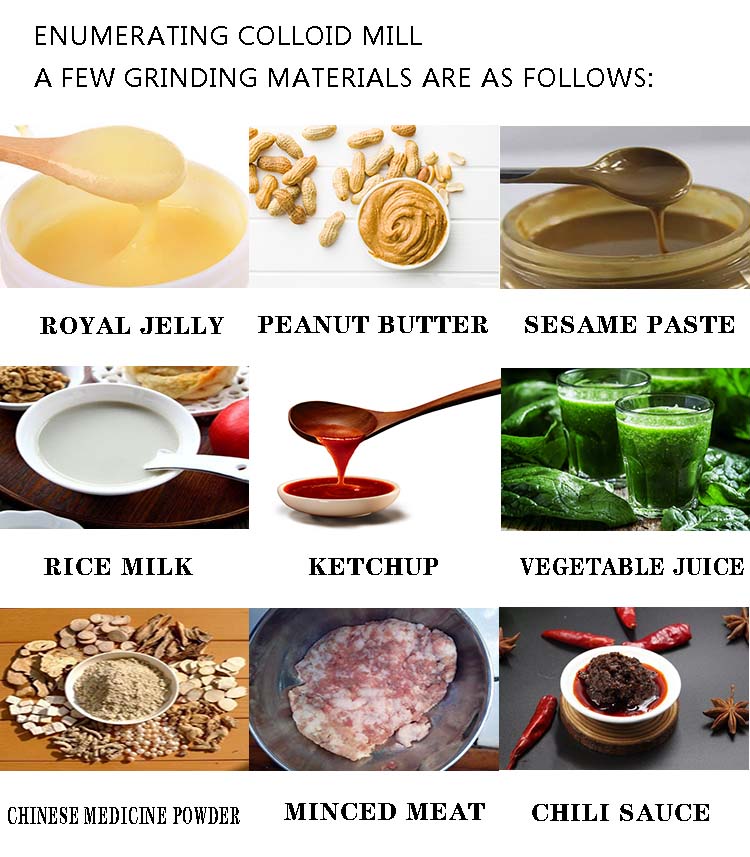

Another feature of the colloid mill is that it mainly deals with slightly viscous materials and some fluid and semi-fluid materials, and pulverizes them. The similarity is that the colloid mill also has a certain grinding effect on the material, and the grinding material is worthy of ultra-fine grinding, which is a similar effect between a colloid mill and a grinder.

However, the grinder processes materials with high viscosity. It mainly uses its processing drum to repeatedly grind and grind the materials, so that the materials are fully ground and pulverized, while the colloid mill uses the rotation of the dynamic and static grinding discs. The function of grinding and pulverizing the material is one of the main differences between a stainless steel colloid mill and a grinder.

Features and uses of colloid mill

The grinder is more for the processing of relatively high-viscosity materials such as cosmetics, oils and rubber, while the stainless steel colloid mill is more for the processing of fluids, which is another difference between them.

In general, the usage rate of stainless steel colloid mill is still relatively high, especially in the need to pulverize materials, colloid mills are widely used in semi-fluid, fluid and some viscous materials crushing processing