The characteristics and selection basis of the reactor

The reactor is a well-known container. The existing production technology has endowed this equipment with many functions. Therefore, it is widely spread by everyone. It is not only safe and pollution-free, but also used in many industries such as chemical industry, medicine and food. Highly respected. Because the characteristics of the product determine its actual use, and there are many types of reactors, such as stainless steel reactors, enamel reactors, and electric heating reactors, so the application areas of each model will have subtle differences:

1. Stainless steel reactor

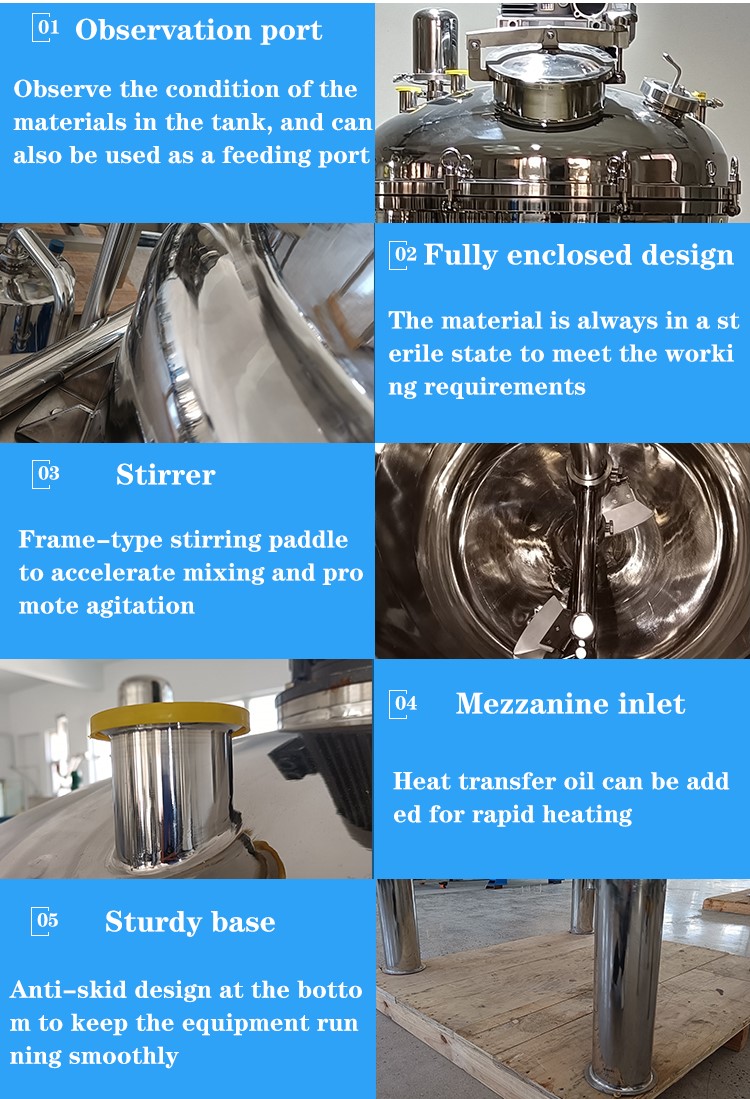

The reaction kettle of this material has the widest application range. In addition to being used in daily food, dye, pharmaceutical, chemical and other industries, it is also used in high-pressure and high-temperature chemical reaction tests; it can not only fully mix the reactants, but also has better High temperature corrosion resistance can be designed and customized according to customer requirements.

2. Enamel reaction kettle

This equipment is suitable for use in the physical and chemical reactions of highly corrosive substances. Under special conditions, it can not only replace stainless steel containers, but also can be used for the production of high temperature resistant parts and radiation source materials. It has both stability and strength.

3. Electric heating reactor

In addition to being used in the above industries, this kind of reactor has also emerged in the light industry, additives and other fields. The equipment is very convenient to operate, intelligent temperature control, and can also be designed with different parameters and structure.

All in all, the reactor is a container that provides a place for physical and chemical reactions, and the types of equipment have different functions. For example, in chemical experiments and pharmaceutical production, the reactor is mainly used to analyze various data; in the petroleum, rubber, and printing and dyeing industries, the reactor is mainly used to complete various nitration, hydrogenation and vulcanization reactions. When you understand the purpose, you can refer to the above information to compare what the actual needs of the industry are, and then find the corresponding reactor equipment. This type of selection is more reasonable.

Stainless steel tube condensers can be divided into three types according to different heat transfer methods: hybrid type, heat storage type and partition type. The equipment is generally made of metal materials, of which carbon steel and low-alloy steel are mostly used in the manufacture of medium and low-pressure heat exchangers; in addition to being mainly used for different corrosion resistance conditions, austenitic stainless steel can also be used as high resistance , Low-temperature materials; nickel alloys are used in high-temperature conditions. In daily production, many customers do not know much about the sealing structure of the reactor when they buy stainless steel reactor, and do not know how to choose?

1. Clarify the basis of seal selection: (1) Working pressure in the kettle; (2) The nature of the working materials; (3) The working temperature of the equipment.

Fom the current point of view, when making and processing electric heating reactor products, the materials selected mainly include: carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel, Inconel) alloys and other composite materials . Because of its different structural design forms, it can be divided into three types: open flat-lid reactor, open butt welding flange reactor and closed reactor. Each structure has its scope of application and advantages and disadvantages. . 2. Clarify the type of seal used in the stainless steel reactor: The sealing device used in the reactor is generally divided into two types: packing seal and mechanical seal. Mechanical seals are divided into single-end mechanical seals and double-end mechanical seals. The complete set of single-machine seals also includes circulating cooling water. , The double machine seal is more complicated, in addition to the water jacket, it also includes supporting brackets, balance tanks, etc.r

The body and lid of the electric heating reactor adopt the line contact between the gasket or the conical surface and the arc surface. By tightening the main nut, they can be pressed against each other to achieve a good sealing effect. When tightening the nut, the force must be gradually increased in a diagonal and symmetrical manner. Tighten with uniform force. Do not allow the lid to tilt to one side to achieve a good sealing effect. When tightening the main nut, the specified tightening torque must not exceed the range of 40~120N.M to prevent the sealing surface from being squeezed or overloaded. The sealing surface should be specially cared for. 3. Choose a suitable seal: Under normal temperature and pressure, the material is not volatile, flammable and explosive, and packing should be selected; when the pressure is less than 4 kg, the material is generally volatile and flammable and explosive. Under the conditions of use, it is necessary to choose a single machine seal; when the working pressure exceeds 4 kg (but less than 10 kg), the material is volatile and flammable and explosive, and the dual machine seal must be selected.

There are usually many ways to heat the stainless steel reactor. If the process requires operation at high temperatures or avoids the use of high-pressure heating systems, other media can be used instead of water and steam, such as mineral oil, diphenyl ether mixture, melting Salt, liquid lead, etc. 4. The advantages and disadvantages of various seals: the price of packing seal is relatively cheap, but it is only suitable for ordinary use conditions and materials; the price of single machine seal is moderate and can be used under most use conditions; while the price of double machine seal is more expensive, but it is more demanding Must be used under different working conditions.