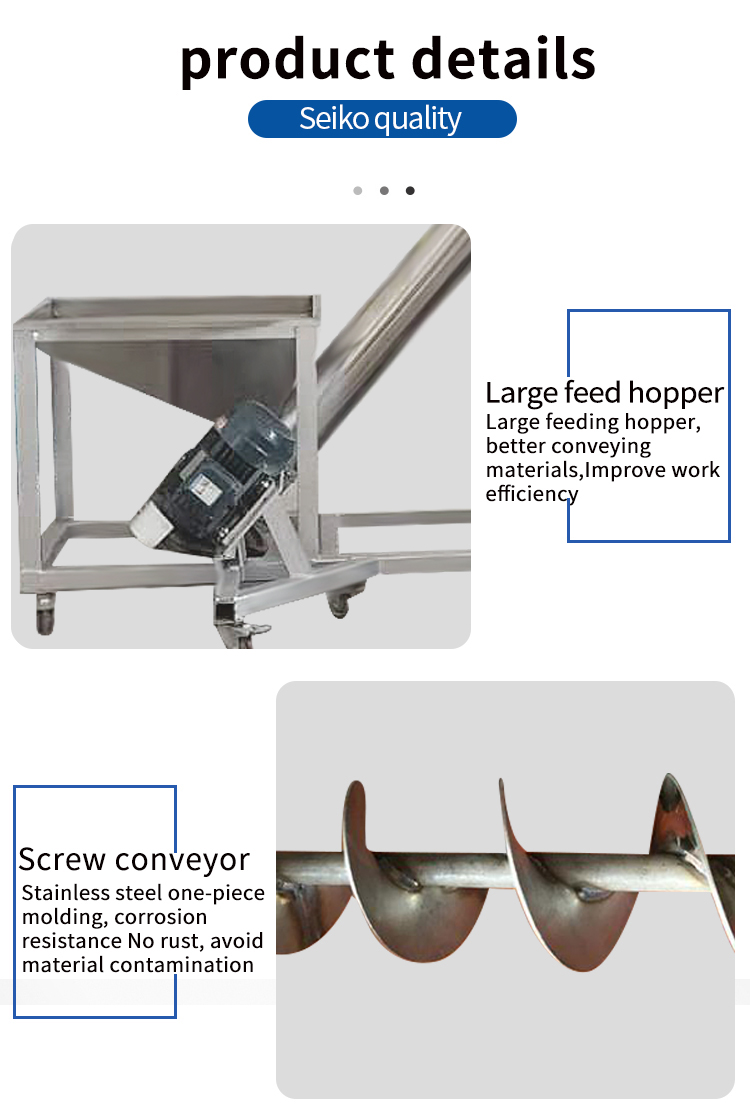

Today we will introduce a tubular spiral feeding machine

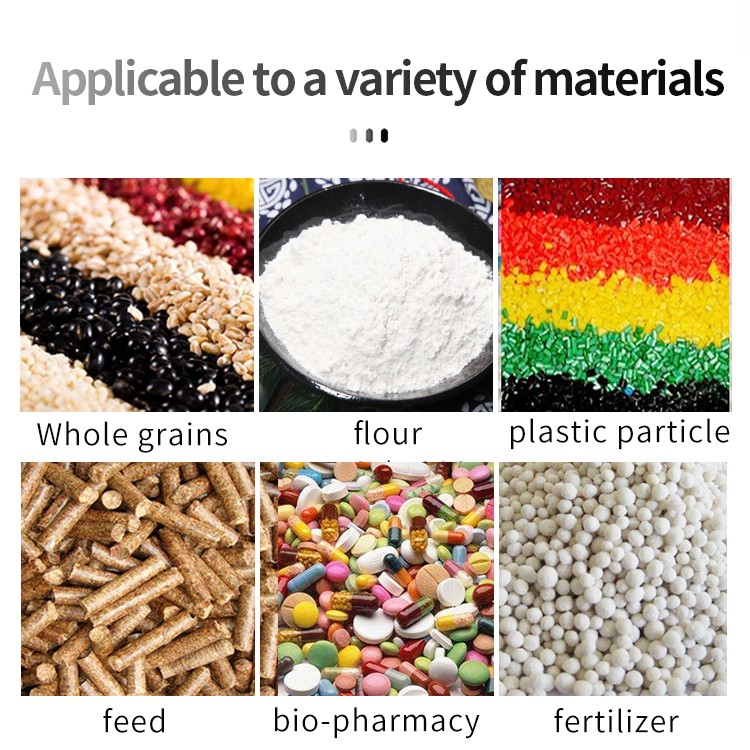

Spiral conveyors are suitable for conveying powdered, granular, and small materials, such as grain, feed, coal powder, cement, clinker, compound fertilizer, grains, rapeseed, and other grain purchasers, as well as feed factories, chemical factories, fertilizer factories, and other conveying materials.

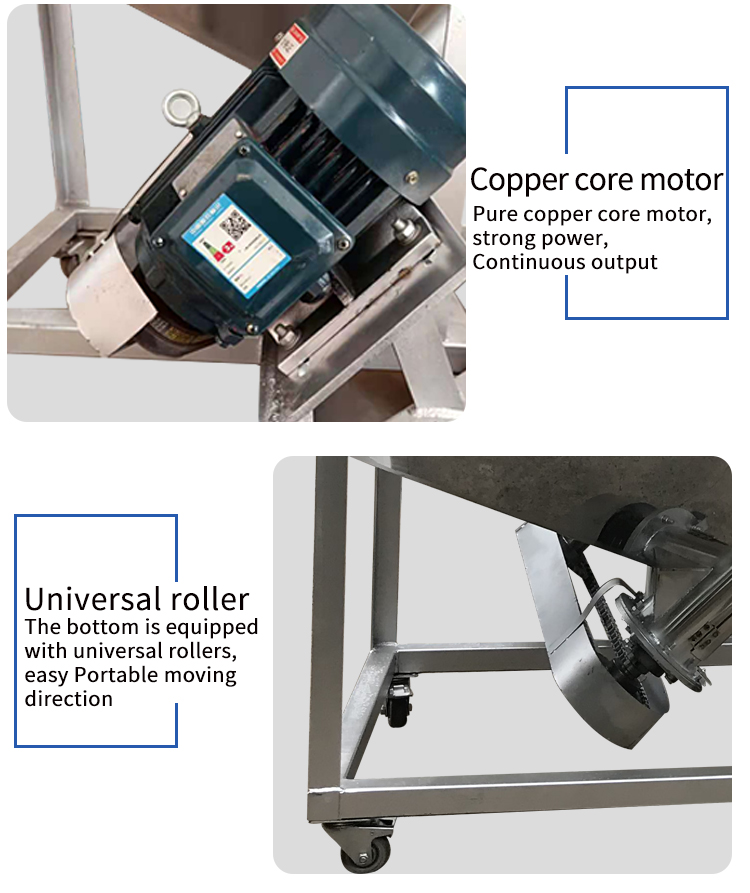

A screw conveyor is a mechanical device that uses an electric motor to drive a screw to rotate and move materials to achieve conveying purposes. Spiral conveyors can transport horizontally, obliquely, or vertically, with advantages such as simple structure, small cross-sectional area, and good sealing. In terms of conveying form, they are divided into axial screw conveyors and non axial screw conveyors, and in terms of appearance, they are divided into U-shaped screw conveyors and tubular screw conveyors.

Spiral conveyor features:

1. It has a wide range of use and can be used to transport materials tilted, horizontal, or vertical upwards. It requires less space, has a large lifting angle, is easy to clean, and is easy to maintain</ H2>

2. Suitable for transportation in various environments, with characteristics such as acid, alkali, and salt water resistance. The entire machine has small size, high speed, accurate, fast, and uniform transportation speed.

3. The discharge end is equipped with a cleaning device, which has low noise and strong adaptability. The position of the inlet and outlet is flexible.

4. Different specifications of feeding machines can be customized according to customer needs, such as hopper size, conveying height, motor position, etc. The screw conveyor has a compact overall size and is easy to maintain.