Today we introduce a stainless steel planetary stirring and boiling pot

The planetary mixing pot is used for stirring, heating, steaming, and frying various high viscosity sauces: baking and filling frying industry (jam, lotus seed paste, bean paste, fruit paste, candied fruit, jujube paste), meat product cooked food processing industry (braised, meat sauce, beef sauce, seafood sauce), seasoning industry (hot pot base, instant noodle sauce, fragrant sauce), candy industry (jam

Sugar processing, vegetable and corn processing (mushroom sauce, chili sauce), hotel supplies

And food processing industries such as fast food (soup, cooking, stewing, porridge).

Mainly composed of pot body, frame body, stirring system, heating system, speed control transmission device, stirring Composed of mixing shaft, pot flipping system, etc,

1. Pot body: The pot body of this product is a semi spherical stainless steel pot body formed by one-time stamping

The overall roundness error is small, and the fit between the mixer and the pot body is high, avoiding burning the pot

Phenomenon appears.

2. Heating system: using steam (jacket heating (steam)), gas, and electric heating

Multiple heating forms such as thermal oil and electromagnetic heating are available for customers to choose from.

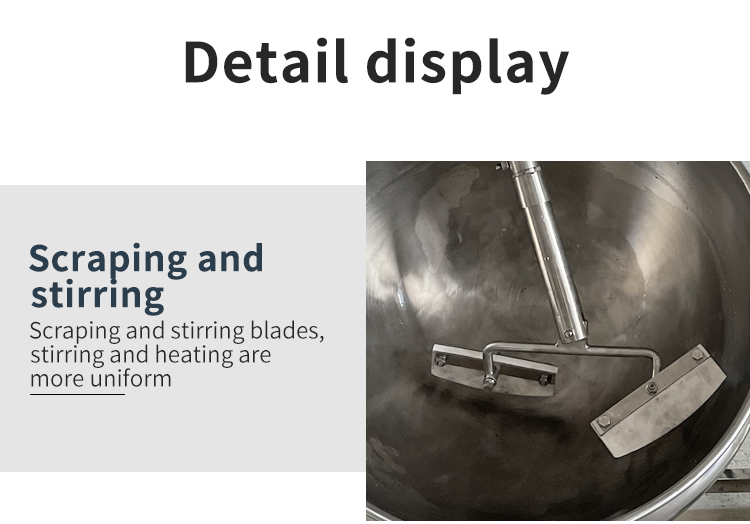

3. Mixing system: The mixing method adopts inclined rotation, so that the planet is the mixer and the pot body

Fully contact and achieve a non integer rotation ratio between rotation and self rotation, so that there are no mixing dead corners in the pot,

The material is stirred and mixed more evenly, and the mixer uses a PTFE scraper to adhere to the pot body

High degree, scraping the bottom is not easy to cause burnt pot phenomenon.

4. Speed control transmission device: The mixing shaft uses a rotating and sealing structure to keep the pot clean,

Hygiene, variable frequency speed regulation power is used for smooth operation.

5. Pot flipping system: hydraulic lifting method, achieving mixing and separation from the pot body before operation

Hydraulic tilting material pouring, capable of tilting at a 90 ° angle, with no dead corners, easy to clean, and reduces labor intensity

Degree. Manual: The entire pot is manually flipped and discharged through worm gears and worms, ensuring stability.

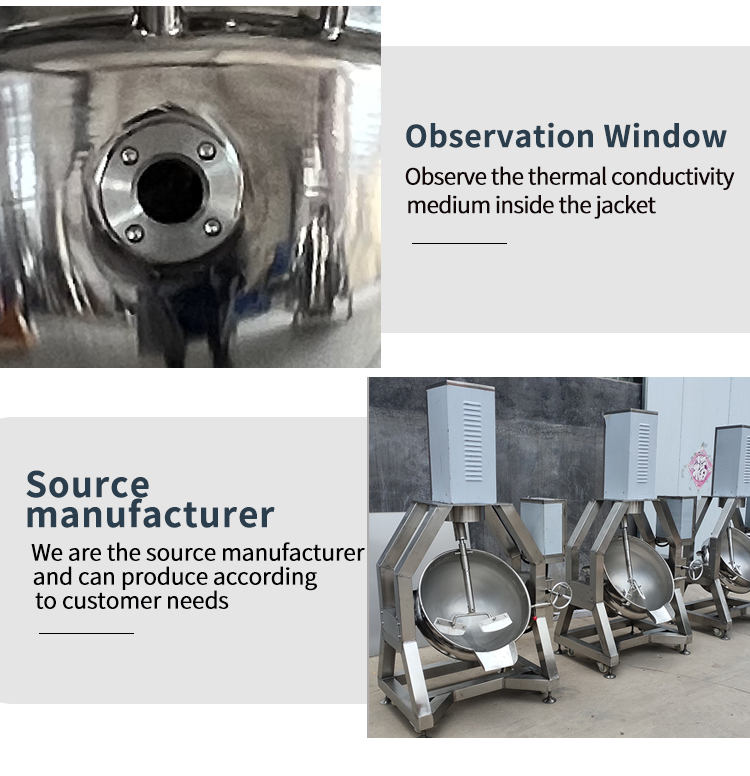

6. The frame body is made of 304 stainless steel and polished to meet the requirements,

Featuring beautiful appearance, reasonable design, compact structure, easy installation, simple operation, and convenience

repair.