Today we will take a look at the production process of colloid mill

Colloidal grinding is suitable for homogenizing, emulsifying, mixing, and crushing various semi fluids, fluids, emulsions, and emulsions of sesame paste, peanut butter, tomato paste, chili paste, filling bean paste, lotus seed paste, egg yolk, jujube paste, bone paste, semi solid materials, emulsified asphalt, paint coatings, and other semi fluids.

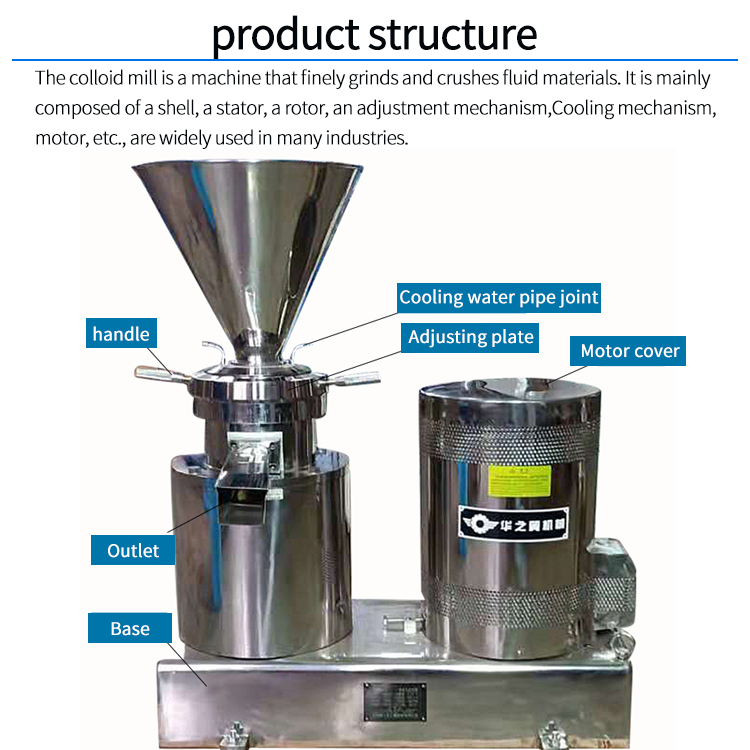

Colloid mill discharge port:

1. The circulating pipe is suitable for materials with low viscosity that need circulating reflux grinding, such as soybean milk, fruit and vegetable juice, drinks, etc.

2. The square mouth is suitable for materials with medium to high concentrations that do not require reflux grinding, such as peanut sauce, chili sauce, meat paste, etc.

The working principle of a colloid mill is shearing and grinding, relying on the relative motion of two tooth surfaces, one rotating at high speed and the other stationary, to subject the material passing between the tooth surfaces to great shear and friction forces. At the same time, under the action of complex forces such as high-frequency vibration and high-speed vortices, the material is effectively dispersed, emulsified, crushed, and homogenized.