Today, let's learn about the production process of colloid mill

Colloidal mills are divided into two types according to their structure: vertical colloid mills and horizontal colloid mills. They are used for crushing and grinding fluid and semi fluid materials, with strong adaptability, reasonable structure, simple operation, and more convenient maintenance.

Colloid mill discharge port:

1. The circulating pipe is suitable for materials with low viscosity that need circulating reflux grinding, such as soybean milk, fruit and vegetable juice, drinks, etc.

2. The square mouth is suitable for materials with medium to high concentrations that do not require reflux grinding, such as peanut sauce, chili sauce, meat paste, etc

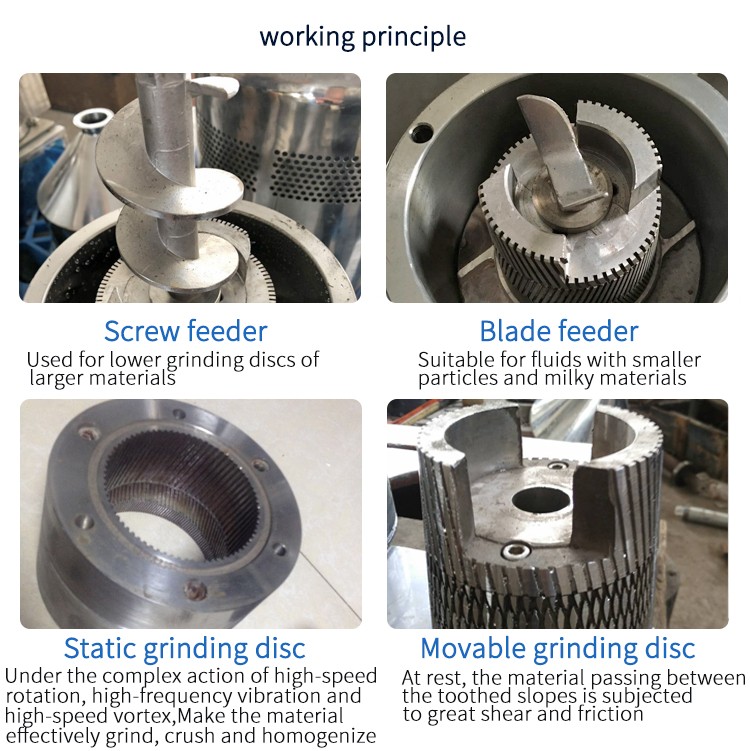

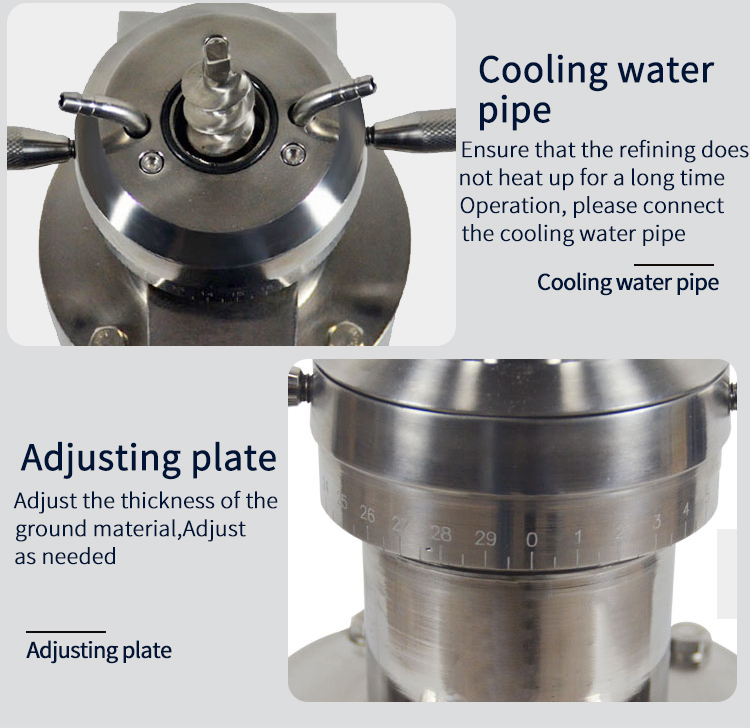

Colloidal mill is a machine that grinds and crushes fluid materials, mainly consisting of a shell, stator, and rotor. The regulating mechanism, cooling mechanism and motor are widely used in many industries, such as peanut paste, soybean milk, dairy products, dairy products, vegetables, peppers, mung beans, yams, carrots, bone mud, asphalt and other fluid materials grinding.

Introduction to colloid mill:

1. The material is made of either whole machine stainless steel or material contact surface stainless steel, which is not easy to corrode and has a beautiful appearance.

2. Colloidal mills are structurally divided into two types: vertical and horizontal.

3. The product design has a compact structure, stable operating performance, low energy consumption, and good sealing.

4. Simple operation, high production efficiency, and strong adaptability.

5. It can be made according to customer requirements and supports customization.