Working principle of vacuum reactor

Reactors are widely used in industries such as coatings, building materials, pigments, resins, food, and scientific research. Suitable for mixing and stirring different materials, such as shampoo, shower gel, cosmetic water emulsion, adhesive, ink, paint,etc. It can also be used to mix, dissolve, and evenly mix and stir according to customer requirements. It can also be made into a physical equipment with functions such as heating, homogeneous emulsification, temperature control, and cooling according to customer requirements.

A vacuum reactor is a device used for chemical reactions or material processing under low pressure conditions.

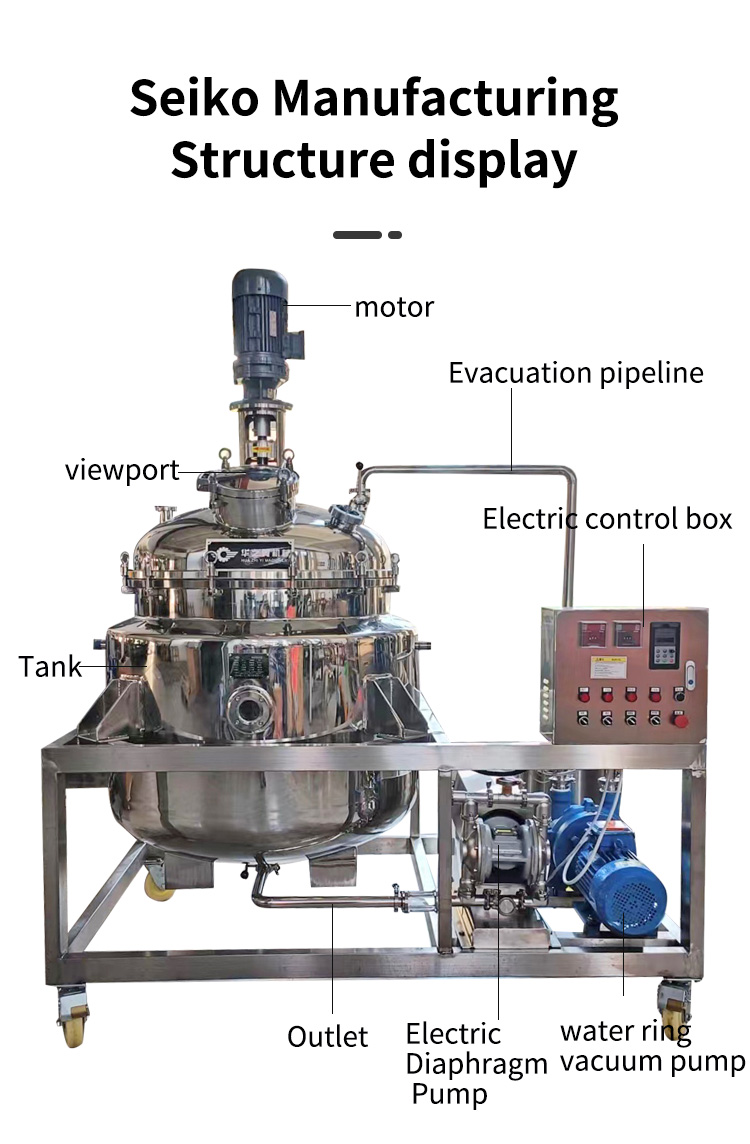

It usually consists of a reaction vessel, heating system, cooling system, stirring system, vacuum system, and control system.

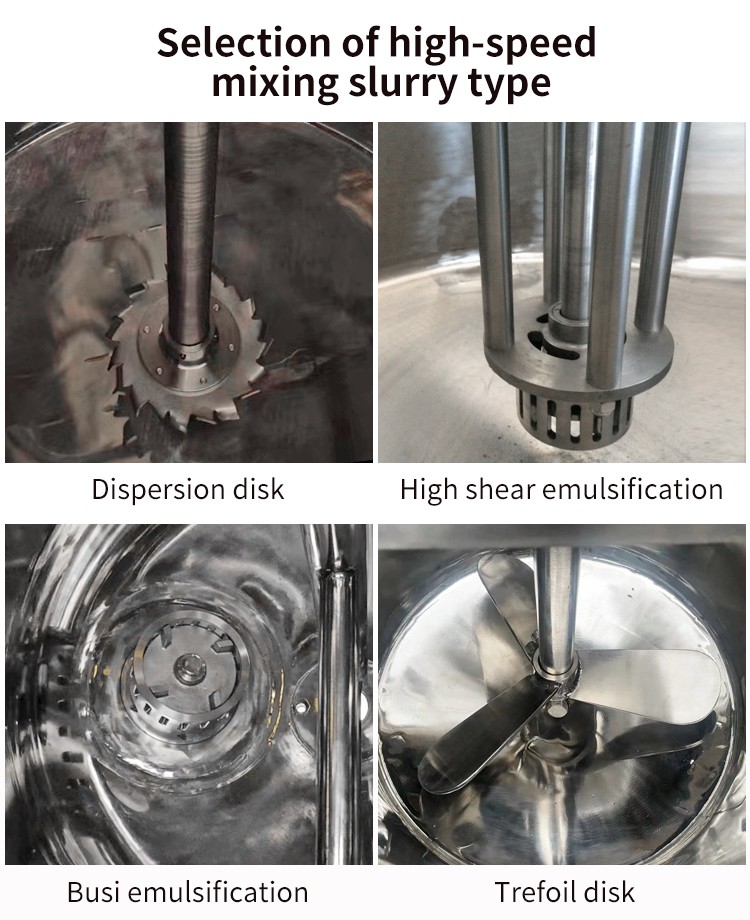

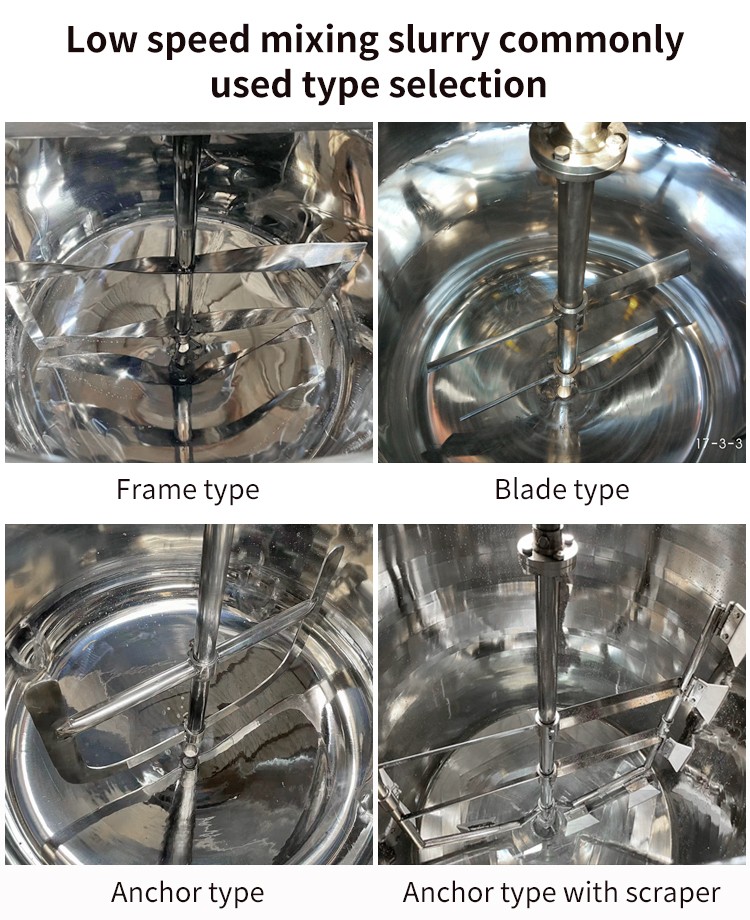

The working principle of a reaction kettle is to add reactants to a reaction vessel, and control the temperature, pressure, and stirring speed during the reaction process through a heating/cooling system and a stirring system, causing the reactants to undergo chemical reactions and ultimately obtain the required products.

Reactors can be divided into different types based on different reaction conditions and the characteristics of reactants, such as atmospheric pressure reactors, high-pressure reactors, vacuum reactors, stirred reactors, etc. Different types of reaction kettles need to be selected based on specific circumstances when used.

![]()