Today we will introduce a three legged centrifuge for material dehydration

Its working principle is driven by a motor to rotate the drum at high speed, generating centrifugal force. Centrifugal force is hundreds of times the acceleration of gravity, which can quickly throw solid particles in the mixture towards the drum wall, while liquid is discharged through filter cloth or gravity.

Attention: It is necessary to control the viscosity of the material, prevent the filter cloth from clogging, and regularly maintain the equipment. Based on the above principles and structural analysis, the three legged centrifuge has become an indispensable equipment in industrial production due to its efficient separation ability.

When the mixture is injected into the conical drum of the centrifuge, due to the centrifugal force of high-speed rotation, solid particles will deposit on the inner wall of the drum to form a solid layer, while the liquid is discharged from the centrifuge. As the solid layer inside the drum gradually thickens, the processing efficiency of the centrifuge will gradually decrease. In order to prevent the solid layer from becoming too thick, the centrifuge will be equipped with a discharge device to continuously discharge solid particles from the drum. The discharged solid particles can be further processed or recycled through different treatment methods.

Advantages of Three Leg Centrifugal Dehydration Machine

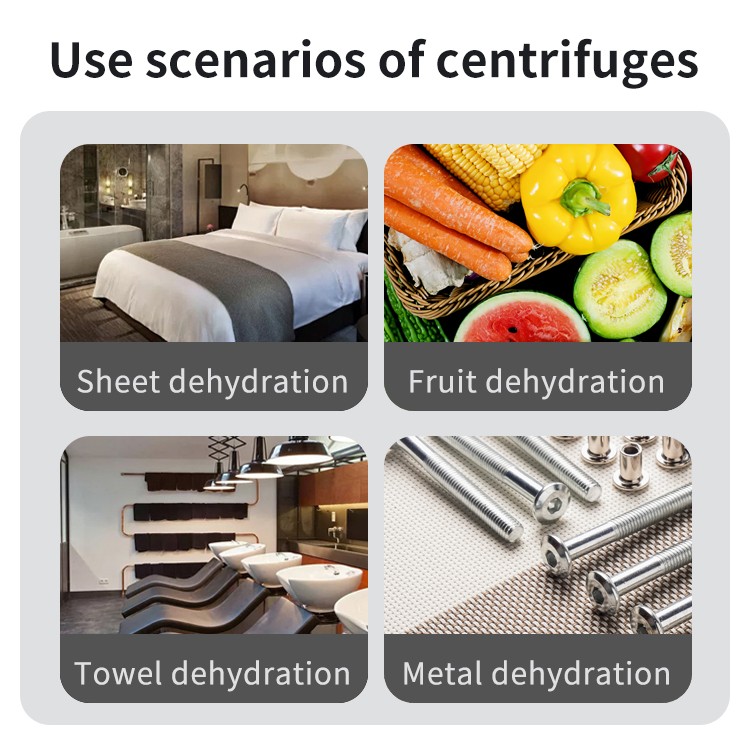

1. Strong adaptability: It can handle materials with particle sizes ranging from 10 μ m to several millimeters, and has a significant dehydration effect on micron sized fine particles and finished products (such as textiles). By adjusting the separation time, materials with different filtration performance can be adapted.

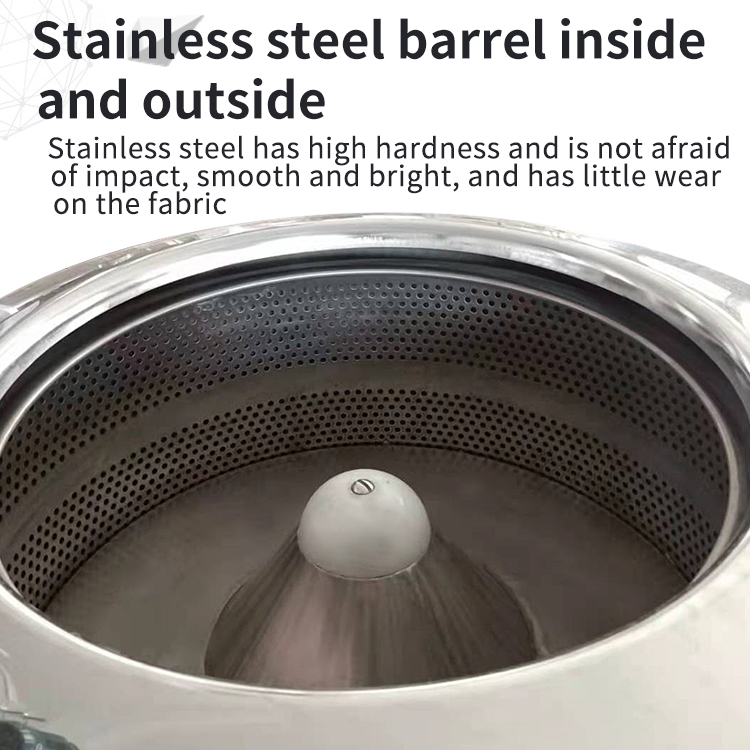

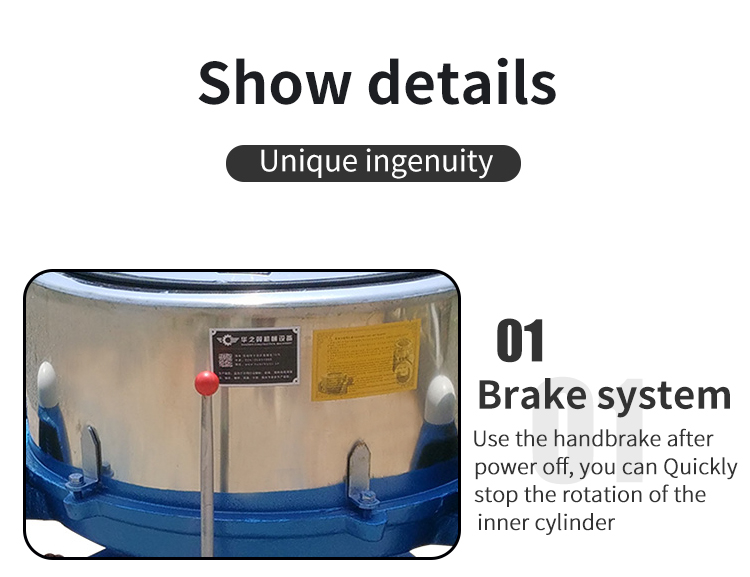

2. Simple structure and low cost: 1. Adopting an elastic suspension support structure to reduce vibration, the machine is compact and easy to maintain. 3. The manual unloading design is simple, with low manufacturing and installation costs. 3. Flexible operation: smooth operation and good sealing, suitable for intermittent or cyclic operation. The separation time can be adjusted to optimize the washing effect of the filter cake.

4. High compatibility: The filter cloth can be replaced for material filtration, and the filter cloth can be cleaned and regenerated, making it suitable for handling materials that require multiple filters.

5. Energy saving and environmental protection: The high-speed rotating mechanism is designed with a closed structure, which is easy to seal and explosion-proof, and meets the requirements of modern industrial environmental protection.