Today we will learn about a small high-speed mixer.

Introduction to high-speed mixer products:

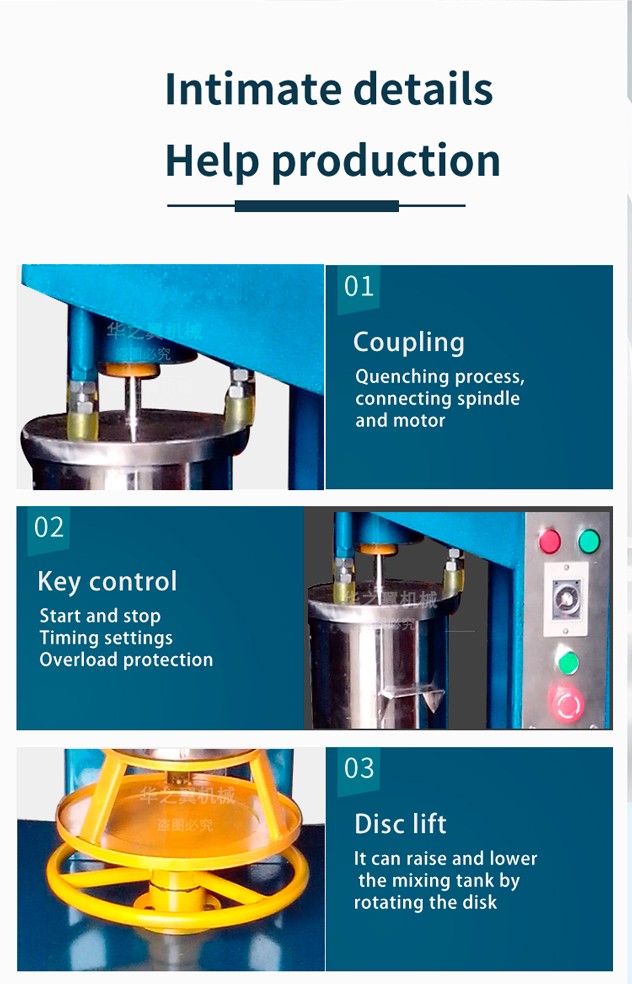

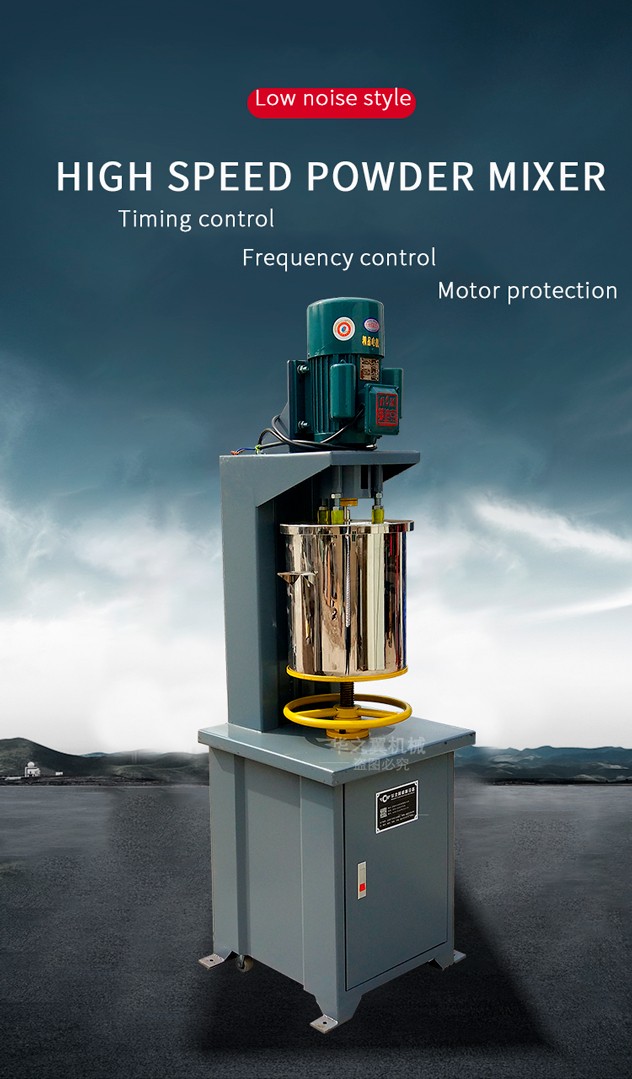

Adopting the design concept of mirror stainless steel powder mixing barrel+welder+new high-speed powder mixing machine, we strive to create a high-speed mixer.

1. Adopting a fully copper core motor, it has a longer service life, stronger power, and saves more electricity when working with a high-speed powder mixer

2. A brand new mirror faced stainless steel powder dispenser with a smooth mirror like surface. The air duct can easily clean the high-speed powder dispenser;

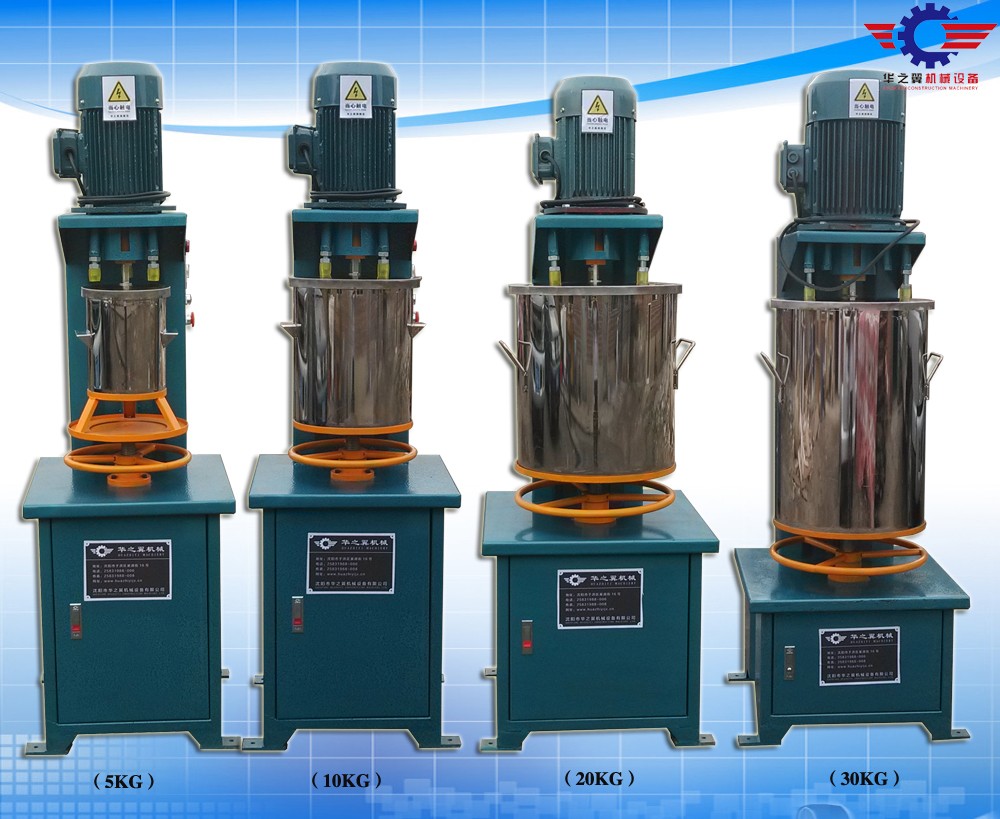

3. Adopting a user-friendly operating system, the high-speed mixer can easily load and unload materials. The high-speed mixer below 20kg adopts manual lifting mode; The 30kg high-speed mixer significantly reduces the height of the tray and reduces the difficulty of loading the high-speed mixer;

Equipped with a small cart above 50kg, the cart is equipped with a hydraulic lifting system for easy and safe lifting.

4. Fully automatic timing function, which can complete time setting with just one timing. When the working time reaches the automatic stop of powder mixing work, there is no need for manual supervision, saving time and labor.

Instructions for use of high-speed mixer:

1. This machine utilizes the principle of mandatory mixing to pour materials into a barrel and achieve uniform mixing under high-speed stirring.

2. After the installation of this machine is completed, it is necessary to test the machine before initial use, check the direction of motor operation, whether there is any abnormal noise during machine operation, and whether the operation is smooth.

3. If everything is normal during the empty machine trial run, the work before feeding can proceed

4. Clean the machine to ensure that there are no impurities contaminating the raw materials

5. Confirm whether the inlet door on the barrel is properly sealed and whether the pressure port is securely fastened.