Reaction kettle customization and structure introduction

Overview of the reactor:

1. The purpose and characteristics of the reactor

The reactor has the advantages of high temperature resistance, corrosion resistance, and strong production capacity.

2.The main points of the structure of the reactor

The reaction pot is composed of a pot body, a pot cover, a stirrer, a heating jacket, a supporting transmission device, and a shaft sealing device.

The pot body and the pot cover are connected by flange sealing, the lower part of the pot body has a feed hole, and there is a stirrer in the pot. The pot cover is opened for feeding, stirring observation, temperature and pressure measurement, extraction steam fractionation, exhaust and other process pipe holes .

The heating jacket of the reaction kettle is equipped with pipe holes such as inlet and outlet oil (steam) temperature measurement, steam release valves, and electric heating rods.

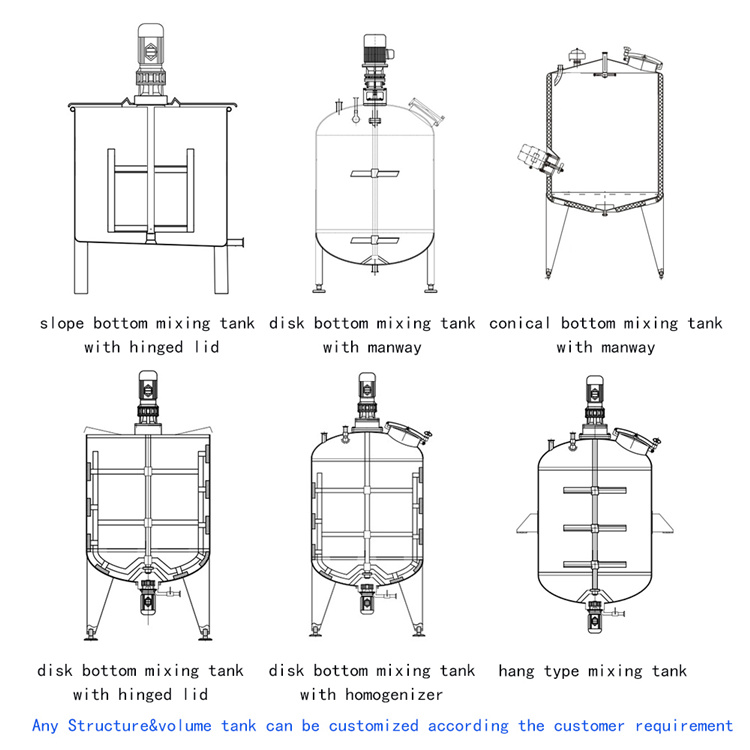

Due to different production processes and operating conditions, users have requirements for pot lid process opening, stirring type (slurry type, anchor type, frame type, spiral type, etc.), support type (suspension type or support type), and packaging and sealing. You can contact our factory to design separately.

Product features of stirred tank/reactor:

1: Suitable for mixing, mixing, blending and homogenizing powder and liquid, or liquid and liquid;

2. Design the structure and configuration according to the customer's production process requirements; more standardized and more humane;

3: In the mixing process, manual and automatic control such as feeding control, discharging control, and mixing control can be realized;

4: It can be purchased separately, or a set of options can be purchased according to the actual situation of the customer;

Reactor/mixing tank mixing device: the top center mixing, the output shaft of the reducer and the mixing shaft are connected with the looper, which is convenient for disassembly and cleaning. Stirring speed: 15~120r/min (constant speed); Impeller type: frame type, anchor type, blade type, turbine type, etc. (according to process requirements). Foot type: round tube or hanging ear type. Equipment configuration: electric control box, thermostat, material and liquid inlet and outlet, medium inlet and outlet (oil inlet and outlet), exhaust port (oil spill hole), etc. Tank material: inner tank SUS304 or SUS316L; outer shell q235-B or SUS304; outer protective shell is SUS304.

Huazhiyi Factory can process: reaction kettle, vacuum reaction kettle, condensation tank, fermentation tank, stirring tank, heating stirring tank, metering tank, stirring tank, stirring tank, evaporation tank, extraction tank, precipitation tank, extraction tank, etc.