Malaysia customer customized palm oil mixing tank

Palm oil is a tropical woody vegetable oil that is extracted from the palm fruit of the oil palm tree, and the oil extracted from the pulp is called palm oil. Palm oil can be refined and fractionated to obtain products with different melting points, which are widely used in the catering industry, food industry and oleochemical industry. Southeast Asia and Africa, as the main producing areas of palm oil, account for about 88% of the world's total palm oil production. Indonesia, Malaysia and Nigeria are the top three producers in the world.

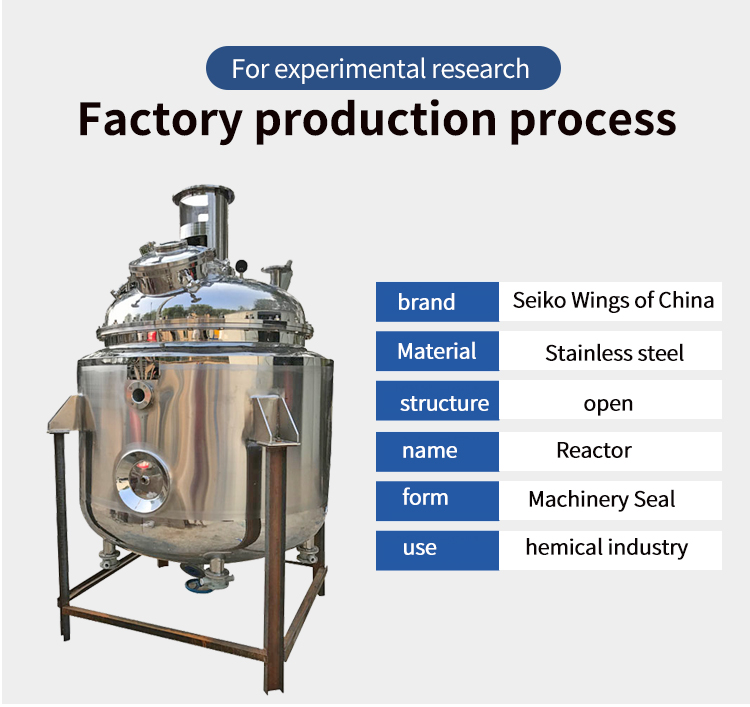

At the end of May, a Malaysian customer contacted us through the foreign trade platform and communicated with the customer in detail to learn that the customer is a manufacturer mainly engaged in the extraction of palm oil chemicals, and wanted to purchase a reactor equipment for the production of palm oil chemicals. After a detailed understanding of the customer's production process, usage, use site and other information, Hengdong's technicians customize a reactor equipment plan and design drawings that meet the customer's needs according to the customer's production needs. After many discussions with the customer's technicians and revision of the drawings, the plan and drawings of the reactor equipment were finally determined, and a purchase order for a double-layer water circulation heating vacuum reactor equipment was successfully signed with a Malaysian customer.

The vacuum reactor customized by Malaysian customers and the material contact parts are made of SS316L stainless steel, and the inner surface of the tank is mirror-polished to ensure hygiene and not easy to produce dead ends. The reaction kettle is heated in the form of water circulation heating. It adopts a vacuum fully enclosed design, and the upper and lower heads of the tank are connected to ensure that the material production process is completed in a sealed state, and the material is safe, hygienic and free from pollution. The reactor body is equipped with double-layer inclined blade paddle, manhole, sight glass, material inlet and outlet, vacuum port, spare port, jacket temperature sensor, weighing module, vacuum pump and other configurations.

At the beginning of June, the production and manufacture of the customized reactor equipment has been completed, and the debugging and testing before leaving the factory have been completed. On June 20, the engineers packed the reactor equipment and shipped it out of the warehouse, loaded it on schedule and sent it to Dalian Freight Port.