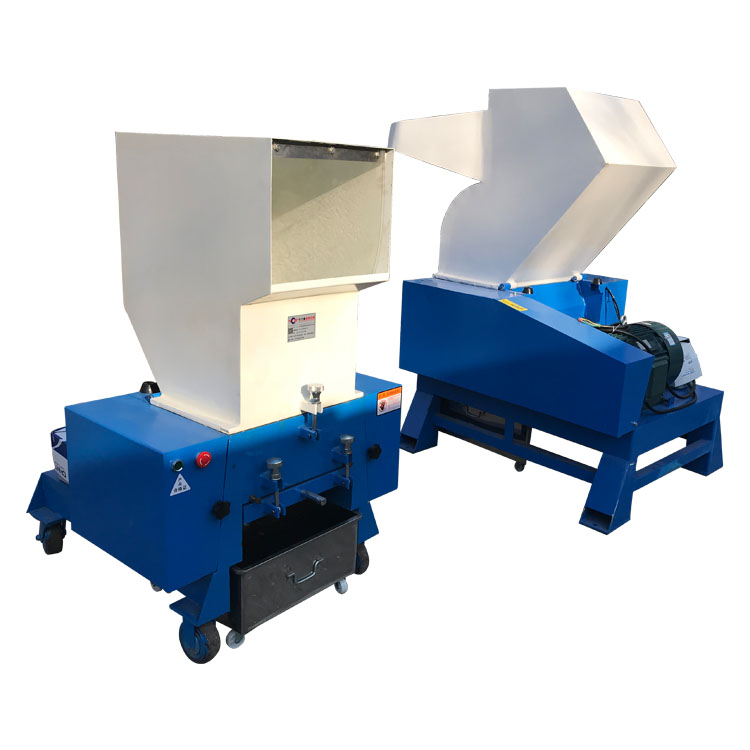

Introduction of automatic waste plastic recycling crusher

Automatic waste plastic recycling crusher machines

The crusher machine is mainly used for crushing wasted plastics like plastic pipes, profile, bottles, film, sheet and so on. The rotary blade of this plastic crusher is one step design to make cutting force resolve and increase the cutting force times.

Plastic crusher refers to pulverizing various plastic plastics and rubbers such as plastic profiles, pipes, rods, threads, films, and waste rubber products.Raw material will be fed into the grind chamber, stroked by the revolving and fixed knives, cut and grinded and automatically runs to the exit by the centrifugal force of revolving object. It has features of compact structure, easy maintain, and low noise.

Since there are many types of plastics, the things that are crushed from plastics are more regular granular, but the raw materials of each different plastic composition must be a plastic crusher with different knives. It is also more troublesome to maintain. In the ABS plastic shredder, the tools used are relatively heavy, atmospheric, and so are the flanges. The plastic shredder has an all-steel welded base, which is sturdy and durable. The spindle is rough, the machining accuracy is high, the operation is stable, and the service life is long. It is suitable for crushing various plastic objects such as thick material, hard material block, material head and so on.

1. The pulverizer and power unit should be installed firmly. If the pulverizer is fixed for a long time, it should be fixed on the cement foundation; if the pulverizer is a mobile operation, the unit should be installed on the base made of angle iron, and the power machine (diesel engine or electric motor) and the pulverizer pulley should be ensured. The grooves are in the same plane of revolution.

2. After the crusher is installed, check the fastening of the fasteners of each part, and tighten them if they are loose. At the same time, check whether the belt tightness is appropriate.

3. After the pulverizer is started, it should be idling for 2~3 minutes, and then start feeding and work if there is no abnormal phenomenon.

Fourth, do not replace the pulley casually, to prevent the crushing chamber from exploding due to too high rotation speed, or the working efficiency of the crusher being affected by the too low rotation speed.

5. Before starting the pulverizer, first turn the rotor by hand to check whether the claws, hammers and the rotor operate flexibly and reliably, whether there is any collision in the shell, whether the rotation direction of the rotor is consistent with the direction indicated by the arrow of the machine, and whether the power machine and the pulverizer are in the same direction. Whether the machine lubrication is good.

6. Pay attention to the operation of the pulverizer at any time during the work, and the feeding should be uniform to prevent blocking the boring car, and do not overload the work for a long time. If it is found that there is vibration, noise, high temperature of the bearing and the body, and material spraying out, it should be stopped immediately for inspection, and the work can be continued after troubleshooting.