Introduction and use specification of jacketed pot

Classification of jacketed pot 1. According to the structure, it is divided into: tiltable jacketed pot, vertical (fixed) jacketed pot structure; 2. According to the heating method, it is divided into: electric heating jacketed pot, steam heated jacketed pot, gas heated jacketed pot; 3 , According to the needs of the process, each equipment with or without mixing is used.

The types of materials that can be processed by the jacketed pot: confectionery and pharmaceuticals, dairy products, wine, pastries, beverages, preserves, canned food and other food processing. It can also be used in large restaurants or canteens to cook soup, stew, porridge, etc., as well as stew and paste , Stew, salsa, etc., good equipment for food processing quality, shortening time, and reducing labor.

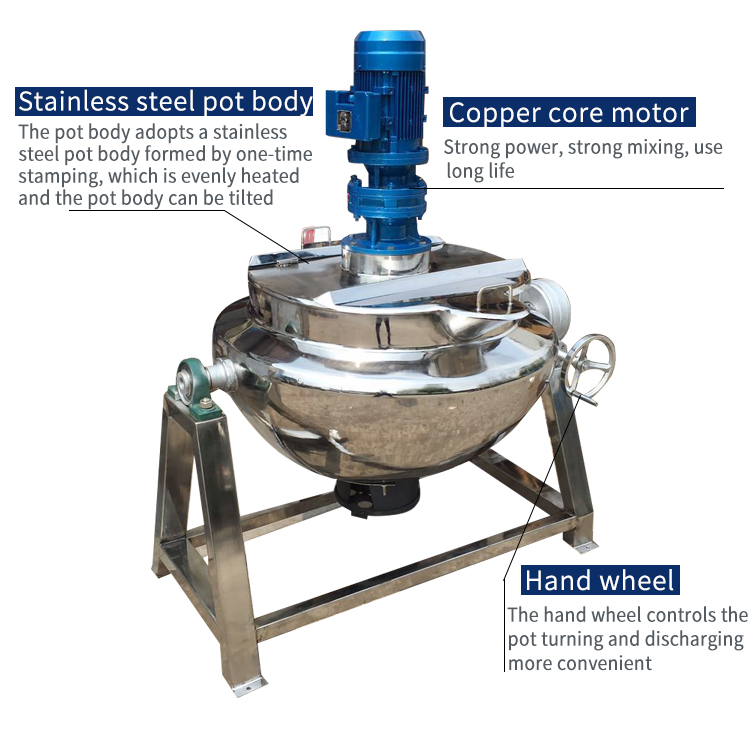

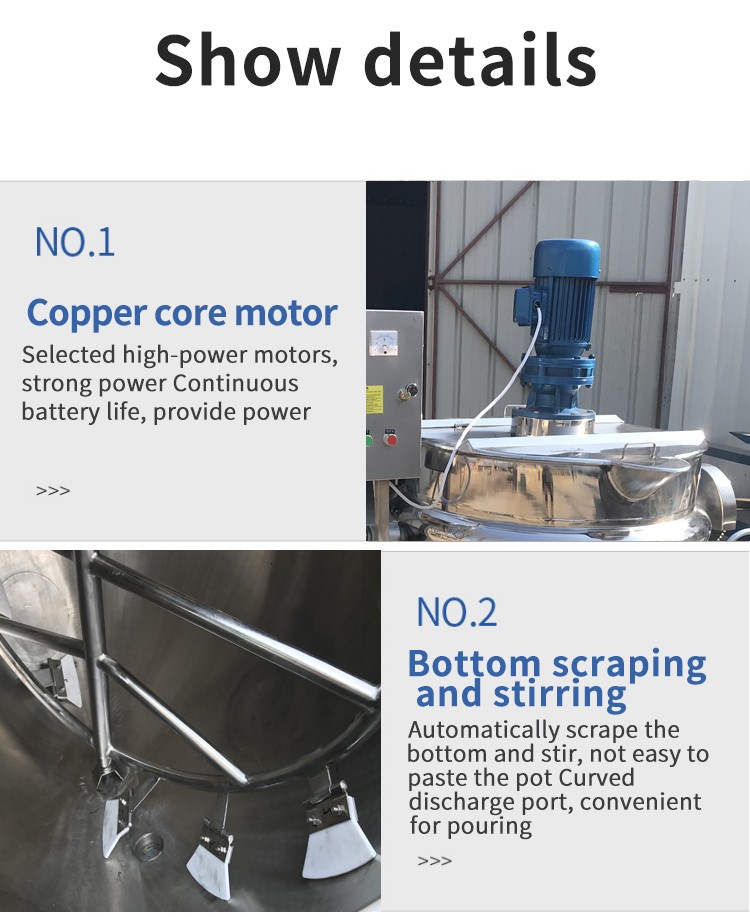

Jacketed pot structure: mainly composed of a pot body and a support; the pot body is a double-layer structure composed of an inner and outer spherical pot body, and the middle interlayer can be added with heat-conducting oil or water. And equipped with pressure gauge, exhaust valve, electric control box. It is easy to install and easy to operate.

Because compressed air is a poor heat conductor, and the steam itself has a certain pressure. Therefore, do not put in compressed air during the process of sterilization and heating, but only need to be in a heat preservation state after reaching the sterilization temperature. After the sterilization is completed, when the temperature is cooled down, the steam supply is stopped, and the cooling water is forced into the spray pipe. As the temperature in the pot drops and the steam condenses, the internal force of the pot is reduced and the pressure of compressed air is used to compensate. In the process of sterilization, attention should be paid to the initial exhaust method, and then the steam can be released and the steam can circulate. It can also deflate every 15 to 20 minutes to promote heat exchange. In short, the sterilization conditions must be met and carried out according to certain procedures. The sterilization temperature, sterilization pressure, sterilization time and operation methods are all specified by the canned product sterilization process.

Stainless steel jacketed pan is a mechanical equipment that improves food processing quality, shortens operating time, improves and saves human resources, and is widely used in various food processing, hotels, restaurants, canteens and other industries. In production, in order to ensure the production efficiency and service life of the jacketed pot in use, we need to pay attention to the following points when operating the jacketed pot.

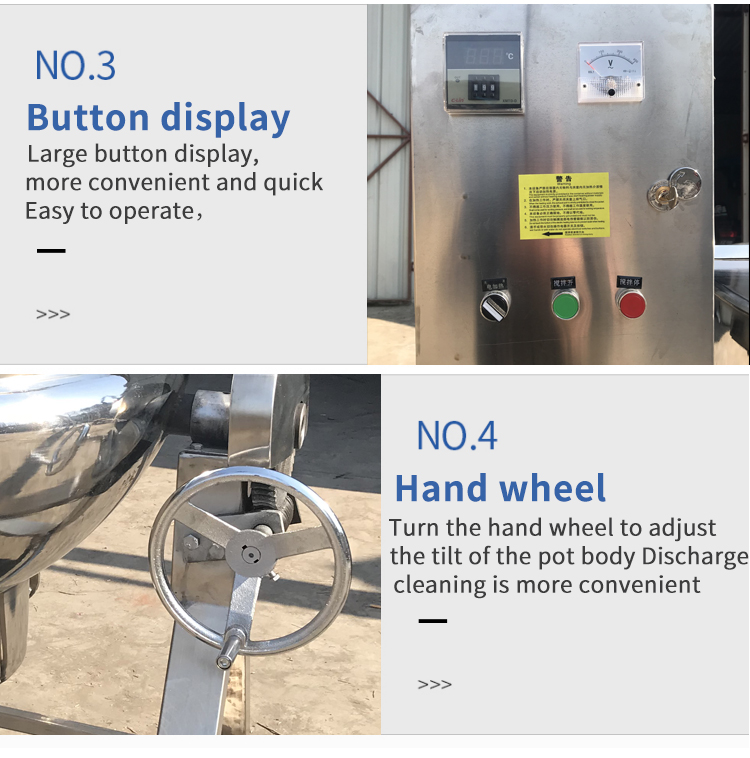

1. Before using the jacketed pot, be sure to check whether the power supply is leaking and whether it has been connected properly. To prevent electric shock during operation, you must keep your hands dry and do not touch the power supply with wet hands.

2. In the process of use, you should always pay attention to the temperature change of the heat-conducting oil, and the temperature of the heat-conducting oil should not exceed 200 degrees.

3. Before each use, you need to oil each rotating part. It is recommended to add cooked vegetable oil to the rotating parts on the surface of the pot, and 30#-40# mechanical oil for other rotating parts, and pay attention to whether the electric heating rod is damaged.

4. After the electric heating jacketed pot heats the materials to the required temperature, the materials are discharged from the bottom of the pot.

5. During use, the vent hole should not be blocked, otherwise it will cause the oil temperature to be too high. It is easy to accident or accident. The vent hole should be blocked when the material is discharged. , To avoid the hot oil spilling and scalding the staff.

6. In order to prolong the service life of the electric heating jacketed pot, after using the jacketed pot, you should first cut off the power supply and add tap water to the pot to protect the electric heating rod and prolong the service life of the jacketed pot.

7. There are two types of mixing structure of the jacketed pot, one is the ordinary mixing structure, and the other is the side scraping mixing structure.

8. In order to keep clean, the pot body should be cleaned every time it is used.

9. The meshing degree of the worm gear and worm should be checked regularly. If the gap is too large, it can be adjusted appropriately through the bearing on the worm.

10. If the machine suddenly fails to work normally during operation, you can check whether the fuse is blown, or whether the AC contactor is damaged, or if it is defective or damaged, it is recommended to replace it.