Today, we will introduce a high-speed dehydration equipment

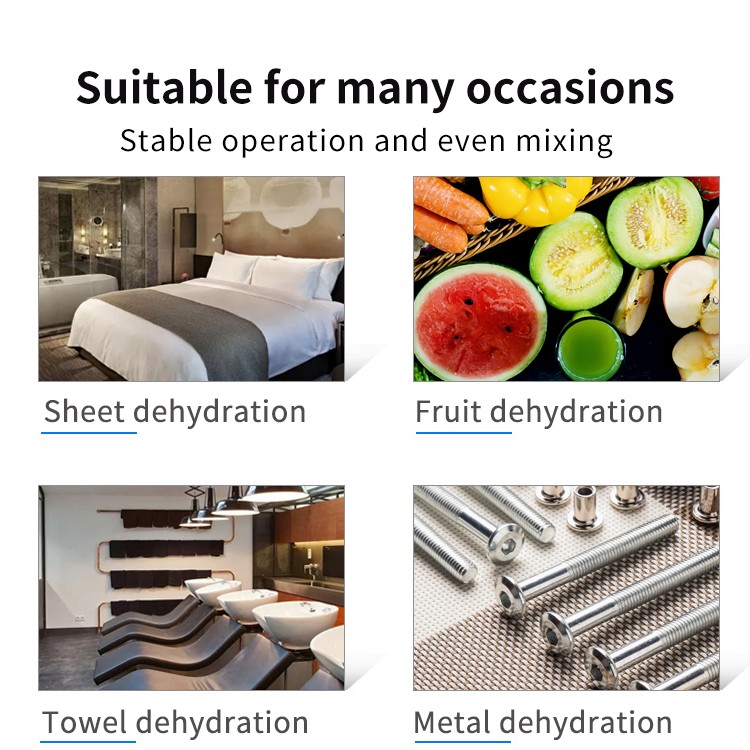

A centrifuge is a separation machine that separates a mixture of solids and liquids (liquid and liquid) to obtain solids and liquids (or liquid and liquid) separately, Industrial centrifugal dehydrator is applicable to textile, printing and dyeing, clothing, hotels, hotels, hospitals, chemical industry, mechanical accessories, latex products and other enterprises.

The industrial centrifugal dehydrator has the advantages of simple and reasonable structure, small wear, low noise and reliability. Industrial centrifugal dehydrator is mainly used for dehydration and drying of various textile (needle) fabrics, clothing,latex products, etc.after washing.

Features of industrial dehydrator:

1.The industrial dryers are all of tripod pendulous structure, which can effectively reduce the vibration of the foundation during operation due to the unbalanced load in the hub.

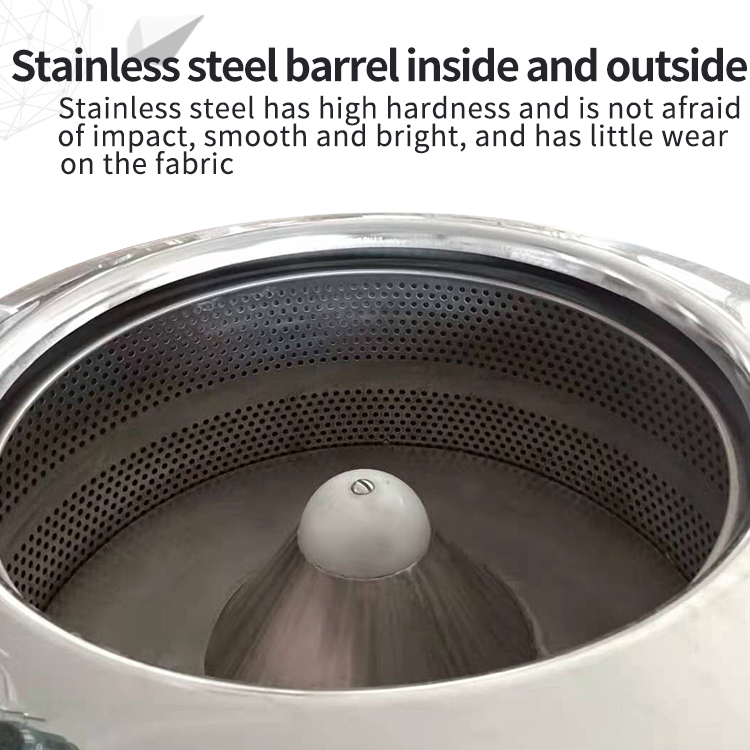

2.The shell and inner liner are made of 304 stainless steel, the cage base and chassis are made of cast iron, and the outlet pipe is under the chassis.

3.The main shaft is made of * * * steel after heat treatment and finishing.

4.The transmission part is driven by triangular belt, and the centrifugal starting wheel is directly driven by the motor, which can make the machine start slowly and gradually reach the design speed, so that the machine can run smoothly.

5.There is a brake opening and closing arm in the machine, which has good braking performance and can stop the machine quickly.

Product details:

1. Overall structure: horizontal tripod swing design is adopted to reduce jitter caused by uneven load.

2. Material: Made of high-quality stainless steel and cast iron, it is not easy to corrode and rust, durable, and has a long service life.

3. Inner liner: made of 201/SUS304 stainless steel according to customer requirements, with dense honeycomb holes, which can improve work efficiency.

4. With the structure of peripheral transmission system, the machine is durable and convenient for customers to maintain the equipment.

Efficient separation:

By generating strong centrifugal force through high-speed rotation, the liquid in the material layer is quickly squeezed out, thereby achieving efficient solid-liquid separation.

Simple structure, easy operation and maintenance:

The three legged centrifuge for manual unloading has a simple structure, easy manufacturing, installation, and maintenance, and low cost.

Shutdown or low-speed unloading, easy to operate, and can protect the grain of the product from damage.

Smooth operation and good seismic resistance:

Adopting an elastic suspension support structure can reduce vibration caused by uneven loads and ensure smooth operation of the machine.

This design also enables the tripod centrifuge to have good seismic performance during operation.

Energy conservation and environmental protection:

In terms of design, emphasis is placed on energy conservation and emission reduction. By optimizing design and improving manufacturing processes, energy consumption has been reduced.

The entire high-speed rotating mechanism is concentrated in a closed shell, which is easy to achieve sealing and explosion-proof, and meets the environmental protection requirements of modern industrial production.

Strong adjustability:

By adjusting the separation operation time, the tripod centrifuge can adapt to various difficult to separate suspensions and flexibly respond to different requirements for filter cake washing.

Long service life:

Due to its sturdy structure and reasonable design, tripod centrifuges usually have a long service life.