Which industries are suitable for stainless steel horizontal mixers

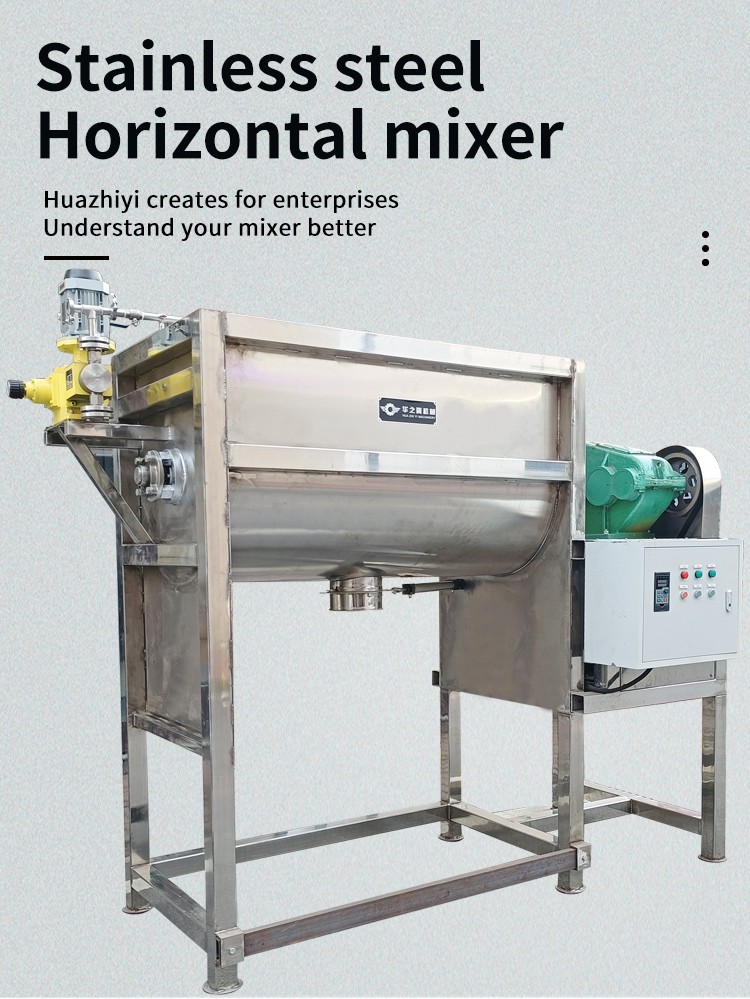

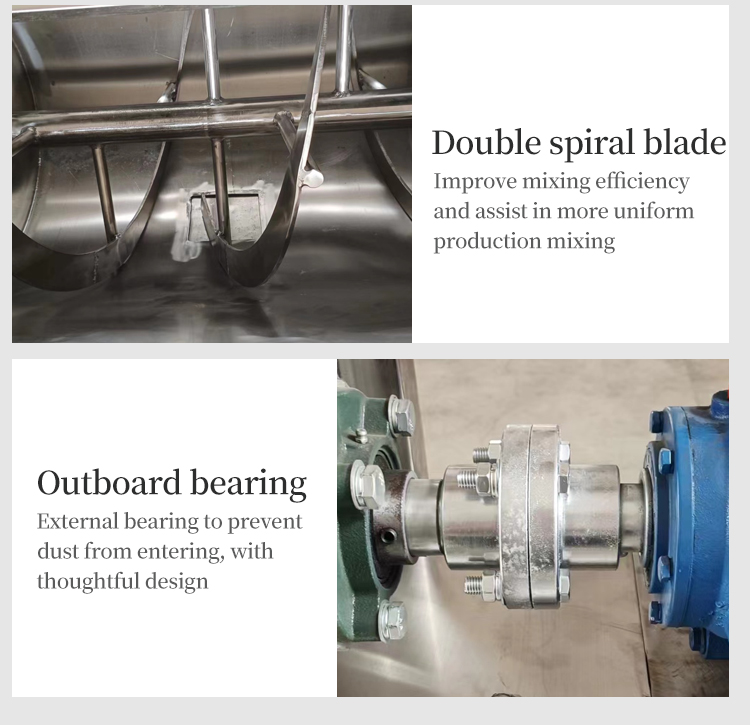

The working principle of a horizontal mixer is to arrange double-layer spiral blades on the transmission spindle, with internal and external spirals (small spiral belts) conveying materials to the outside, and external spirals (large spiral belts) pushing materials inward. Under the convective motion of the double spiral belts, the materials form a low power and high efficiency mixed environment. The inner and outer diameter screws installed on the mixing shaft drive the material inside the barrel, causing the agitator to flip the material within a certain range inside the barrel. When the mixing device is working, the inner screw drives the material near the axis to rotate axially, pushing it from the inside to both sides. The outer screw drives the material near the barrel wall to rotate axially, pushing it from both sides to the inside, allowing the mixed material to mix evenly in a short period of time.

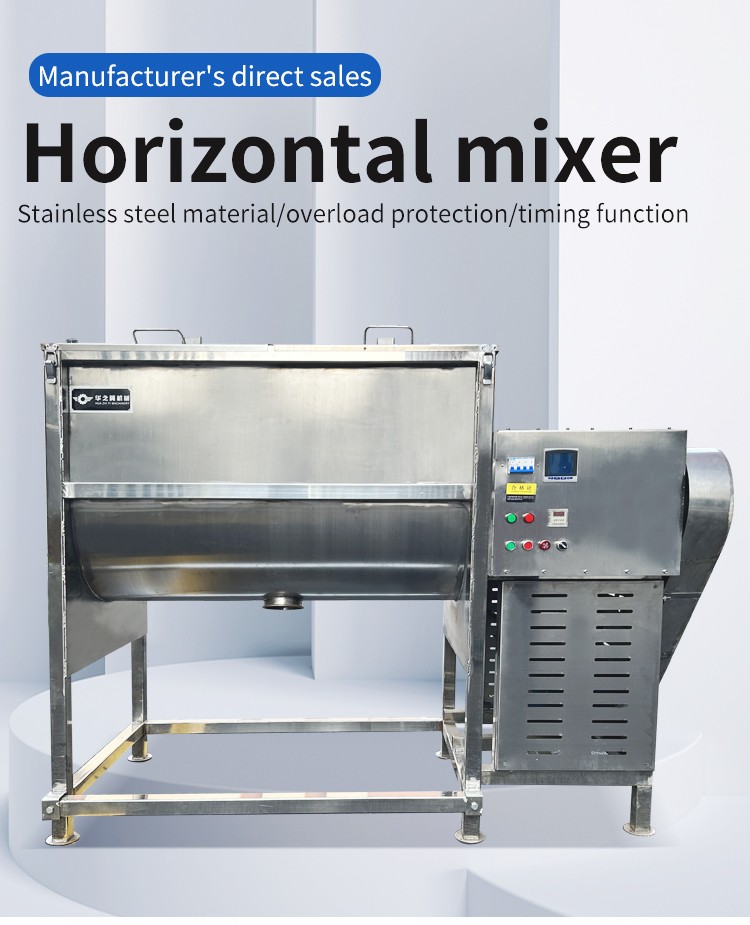

Features of stainless steel horizontal mixer:

1. The material barrel and screw belt are made of stainless steel material, which is easy to clean.

2. Adopting a reducer for deceleration, wear-resistant and durable, with long service life and low noise.

3. Use "S" type single or double screw belts to mix materials quickly, evenly, and without any storage.

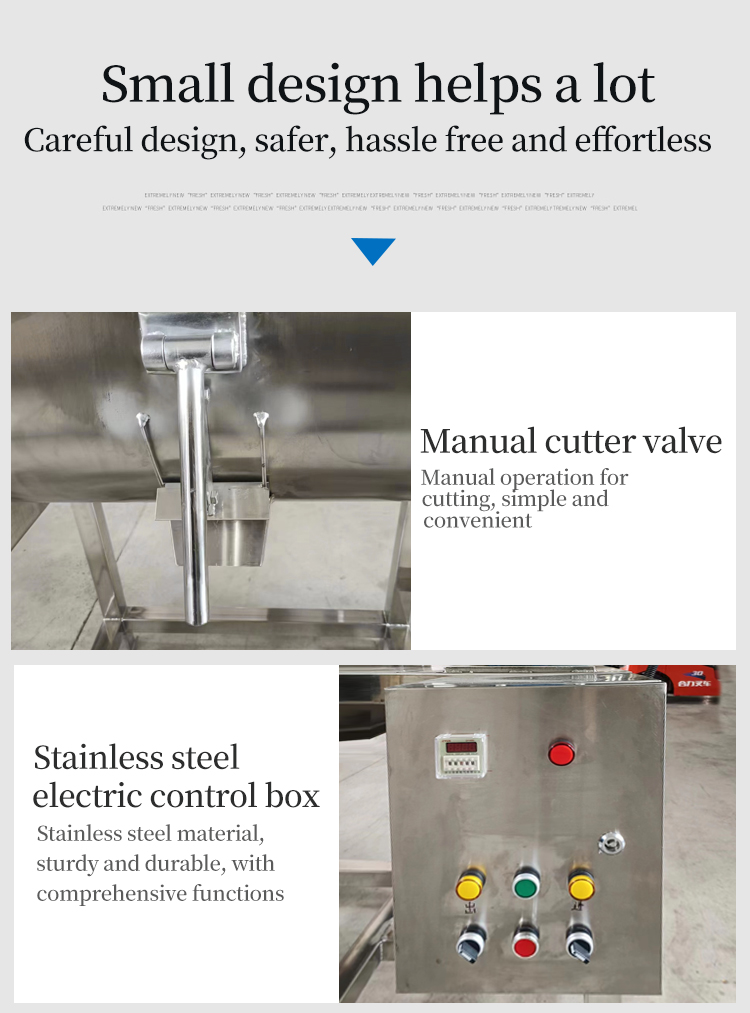

4. The top cover is opened, with a beautiful and elegant appearance, and there is no dust flying during operation, without wasting materials.

Instructions for use of horizontal mixer:

1: Before using heating, please inject 32O thermal oil into the jacket and do not dry burn the heating rod.

2: Before using the mixer, please inject gear reducer oil into the reducer. Change the reducer oil after 100 hours of use for a new machine, and replace it once every six months or a year in the later period.

3: Both ends of the bearings need to be regularly injected with yellow glycerin to prevent the bearings from locking up due to lack of oil.

4: The connecting parts need to be regularly coated with yellow glycerin to provide lubrication.

5: Please turn on the machine before adding materials, do not use under load.

6: Please ensure forward rotation and use, and prohibit reverse rotation.