How to choose a suitable mixing tank or reaction kettle for a daily chemical factory?

Mixing tanks/reactors are mainly used in industries such as chemical engineering, coatings, pigments, resins, food, building materials, agriculture, scientific research, etc., according to customer production processes and needs. Make a regular or heated version; The equipment has a reasonable structural design, advanced technology, durability, and features simple operation and convenient use.

The difference between mixing tank and reaction kettle:

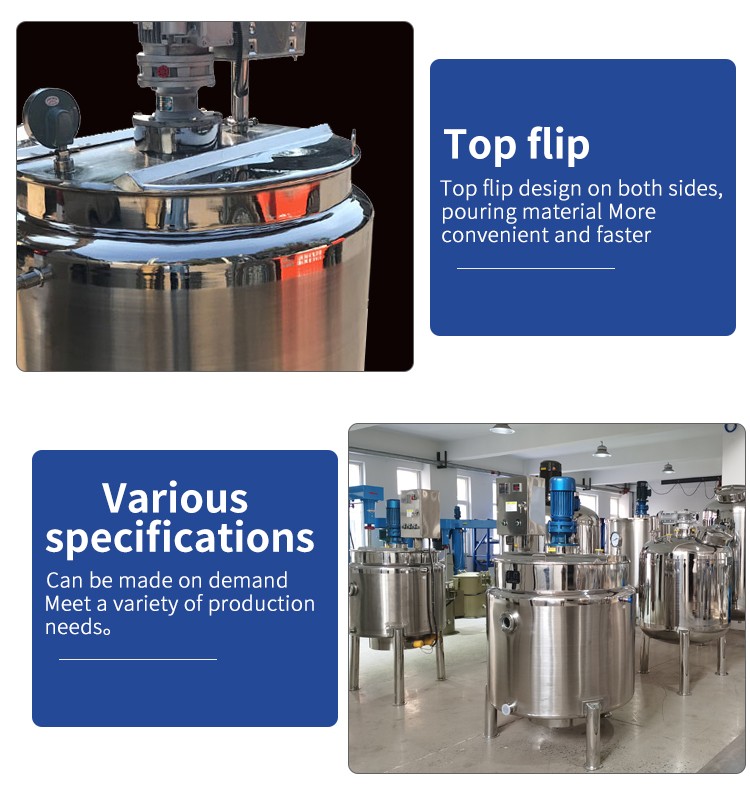

1. Structure: The upper cover of the reactor is either a head structure or a conical structure; The top cover of the mixing tank can be a flat cover structure or a head structure.

2. Sealing: The sealing requirements for the reaction kettle are high, and mechanical seals should be selected; The sealing form of the mixing tank is made into mechanical seal or packing seal according to the requirements.

3. Cost: The structure of the reactor is relatively complex and the cost is high; The structure of the mixing tank is relatively simple and the cost is relatively low.

4. Operation observation: The reactor requires the assistance of accessories such as mirrors, pressure gauges, and liquid level gauges to observe the condition of the materials inside the tank; The open lid mixing tank can observe the material situation inside the tank by opening the lid or observing the population.

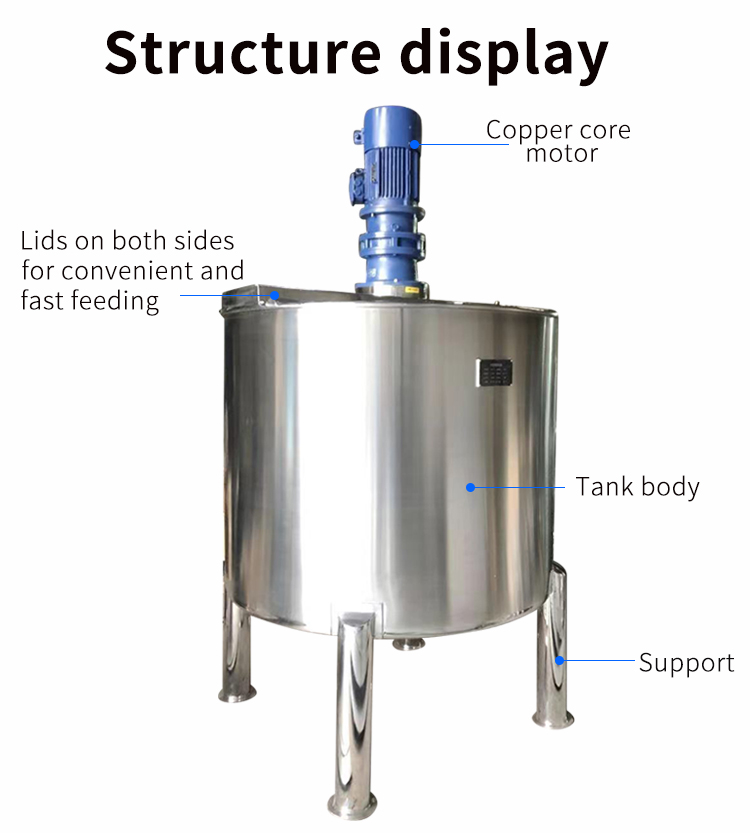

Characteristics of mixing tank:

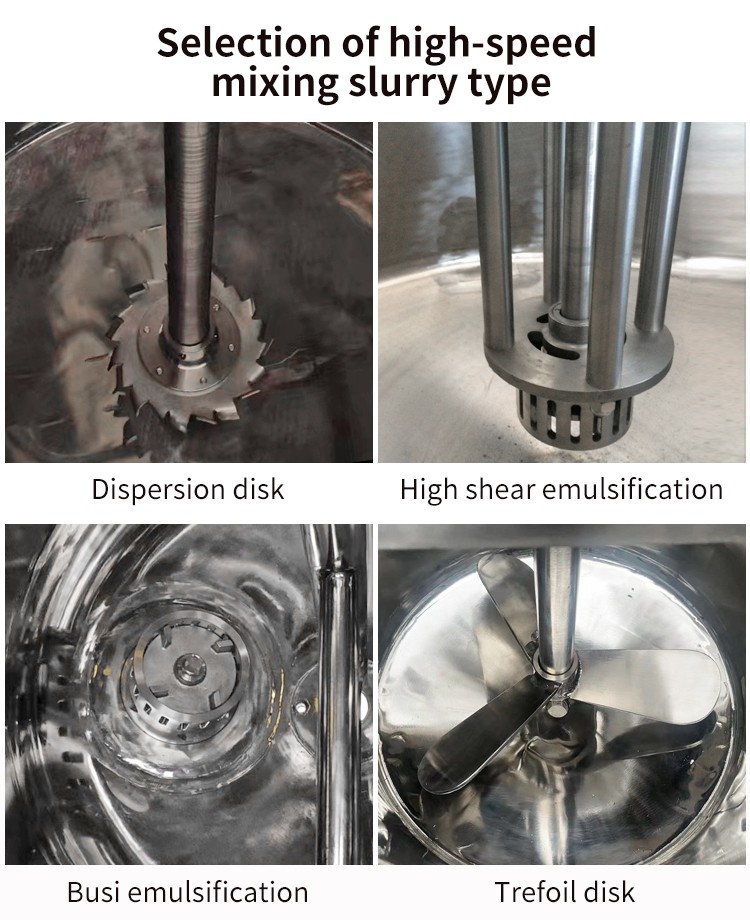

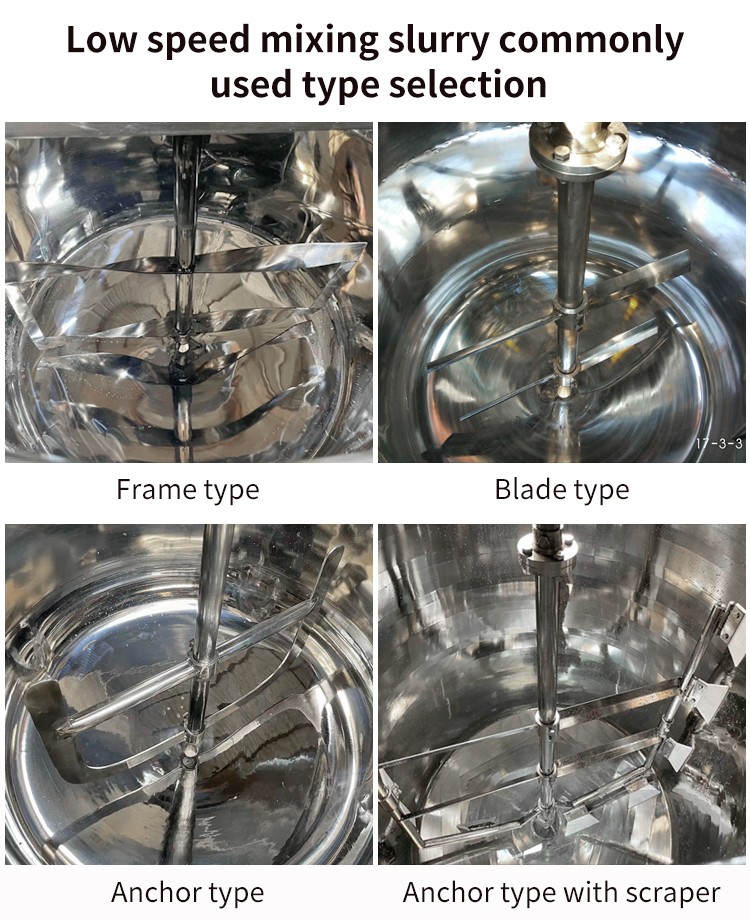

1: Suitable for stirring, mixing, blending, and homogenizing powders and liquids, or liquids and liquids;

2: Design the structure and configuration according to the customer's production process requirements; More standardized and humanized;

3: During the mixing process, it is possible to achieve feed control, discharge control, mixing control, and other manual and automatic controls;

4: It can be purchased separately or as a complete set according to the actual situation of the customer.