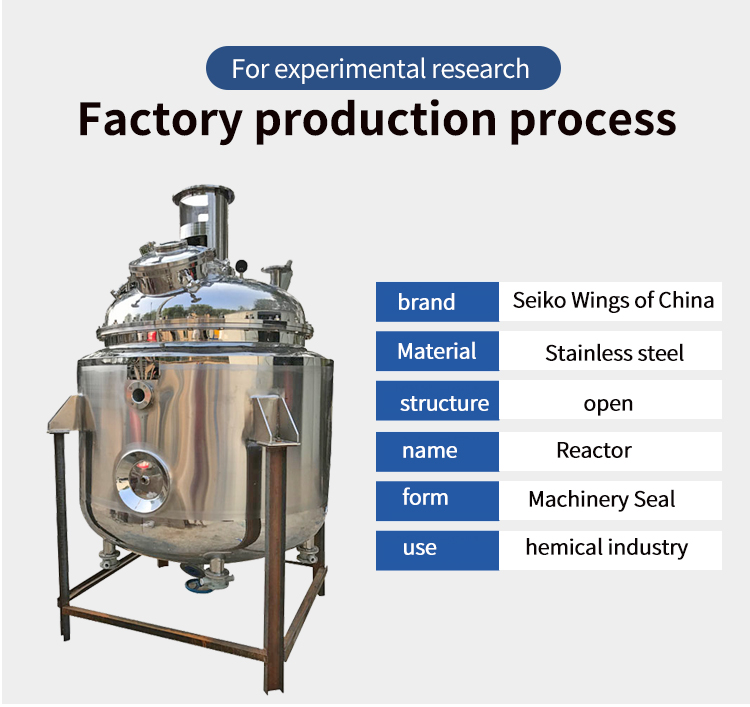

Customizable chemical liquid mixing tank

Stirring tanks/reaction kettles are mainly used in chemical, paint, pharmaceutical, pigment, resin, food, building materials, resin, agriculture, scientific research and other industries, and are used according to customer production processes and needs. Do common type or heating type; the equipment has reasonable structure design, advanced technology, durable, and has the characteristics of simple operation and convenient use;

Electric heating stirring tanks (also known as reaction kettles, hot and cold tanks, batching tanks, mixing tanks, water phase tanks, dissolving tanks, etc.) are widely used in chemicals, coatings, medicine, pigments, resins, food, building materials, agriculture, In scientific research and other industries, the selection of materials is excellent, and the standard is SUS304 stainless steel; other 316L\340, etc. can be selected; this equipment is tailor-made according to the actual needs of customers, such as: vacuuming, heating, cooling, thermal insulation Equipment, etc. to meet different process and production needs, electric heating stirring tank, heating methods include: heat conduction oil heat conduction, hot water circulation heating, coil steam heating; the equipment has a reasonable structure design, large heating area, uniform heating, and heating temperature. Adjustable, for the electric heating type mixing tank, the company has strict requirements on heating and sealing, and the workmanship is meticulous.

The thermal insulation material of the reaction kettle/heating and stirring tank: It is poured and foamed with filled pearl wool, rock wool or polyurethane to maintain the temperature difference with the outside world and achieve the effect of thermal insulation. Surface treatment method of outer shell: mirror polished or primary color matt or frosted matt treatment.

Main technology and structural performance of reaction kettle/electric heating chemical stirring tank: The volume is matched according to the actual needs of customers, such as: 50L, 100L, 200L, 300L, 500L, 600L, 800L\1000L, 2000L~5000L. The heating and stirring tank produced by our company has an optional heating method: generally, an electric heating rod is used to extend into the jacket, and the heating is even and there is no cold zone. Heat transfer oil or water can be injected into the jacket as the heating medium to generate heat energy to heat the materials in the tank. Steam heating can also be used; material heating temperature can be adjusted: ≤ 200 °C (if the temperature is high, it is recommended to add an additional layer of thermal insulation layer); material heating time: 30min ~ 120min (depending on the process needs).