Colloid Mill Instructions and Skills

Our common soap, toothpaste, edible jam, sesame and other products are generally finely pulverized and emulsified by using colloid mill machinery to process the materials. Here, we will introduce the specific use skills of colloid mill and related instructions for use.

Colloid mill usage skills

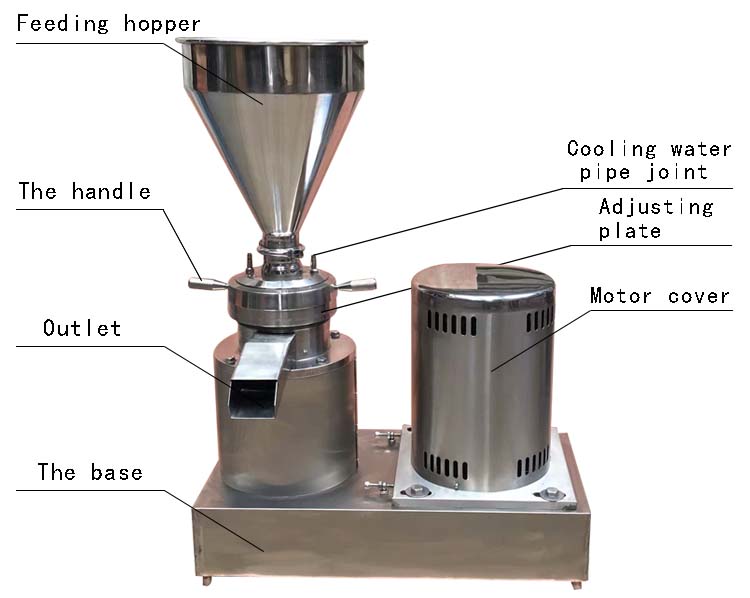

The colloid mill body is mainly composed of an external casing, an internal motor, a transmission device, a cooling device, a dynamic grinding body (rotor), a static grinding body (stator), sealing parts, etc. The use skills need to be divided into several steps:

Inspection of colloid mill before use

1. Check whether the feed and discharge ports and the material pipes are well connected. This step is mainly to ensure that the material will not leak and cause mechanical wear or other problems.

2. Check whether the screws of the body and the tightening screws have been tightened, and then turn the adjusting device used to control the gap between the rotor and the stator counterclockwise to make the gap between the rotor and the stator larger, and then use a professional wrench to check whether the rotor is stuck. A dead phenomenon, if present, needs to be dealt with.

3. Connect through the cooling pipe and drain pipe to determine whether the connection is tight.

4. When the colloid mill is not in use, it is necessary to check the adjustment device, and check the gap between the rotor and the stator to make sure that the gap will not leave space, and try to make the gap of the grinding disc as fixed as possible.

5. After turning on the power, check whether the direction of the motor and the rotor is consistent with the direction of the arrow shown on the colloid mill, that is, attach the clockwise direction, and prohibit reverse rotation, because the reverse rotation will cause the fixing bolts of the rotor to loosen Or fall off, and long-term reverse rotation will also damage the colloid mill.

6. Check the operation of the colloid mill motor, whether the motor, rotor and other components emit noise or strong vibration. If there is such a phenomenon, you need to use a special wrench to check.

7. Operate according to the signs on the cooling device, connect the water inlet and outlet, and connect the cooling water to the body. Generally, the cooling water pressure is about 0.15Mpa, and the water temperature is ≤25 °C. The cooling water can be recycled after being filtered.

8. Turn on the power supply, turn on the motor, adjust the gap between the rotor and the stator, loosen the fastened fixing device, that is, turn the fastener counterclockwise at the same time, it will drive the adjustment ring to adjust, so that we can adjust the rotor and stator. Adjust the gap, counterclockwise is to make the gap larger and the material particles thicker, and clockwise is to make the gap smaller and the material particles thinner.

9. Adjust the gap between the rotor and stator according to the characteristics of the specific material, flow requirements, particle size and thickness. After the gap is controlled, the fastening parts that fix the rotor and the stator are rotated clockwise to fix it.

10. Add materials for production and processing such as shearing, grinding, homogenization, and emulsification.

Colloid Mill Instructions Note

1. After the colloid mill is used, before turning off the power supply, check that there is a certain amount of water in the feed port and feed pipe to ensure that it is in the state of backflow through the circulation pipe. After use, the body needs to be cleaned and disinfected. When cleaning, increase the gap between the rotor and the stator, which is convenient for cleaning and ensures that the material will not remain in the body, causing the material inside the body to adhere. It is also necessary to have an appropriate amount of water before starting to use to ensure that the backflow can be carried out. After the material is put in, it will not affect the motor or sealing parts.

2. Put materials according to the load of the motor operation. If the motor is overloaded, you need to reduce the amount of materials put in

3. During the operation of the colloid mill, it is forbidden to place other items at the discharge port, or close the discharge valve, which will cause excessive internal pressure of the machine and cause leakage, damage and other problems.

4. The airtightness of the body itself is good, and the gap between the rotor and the stator is very small. When the body is working, personnel are required to be present. If problems are found, they will be stopped and checked in time, and the problems will be eliminated before use.

5. When cleaning the colloid mill, it is necessary to use the corresponding cleaning agent according to the characteristics of different materials to clean the body to ensure that all parts of the machine are not damaged.