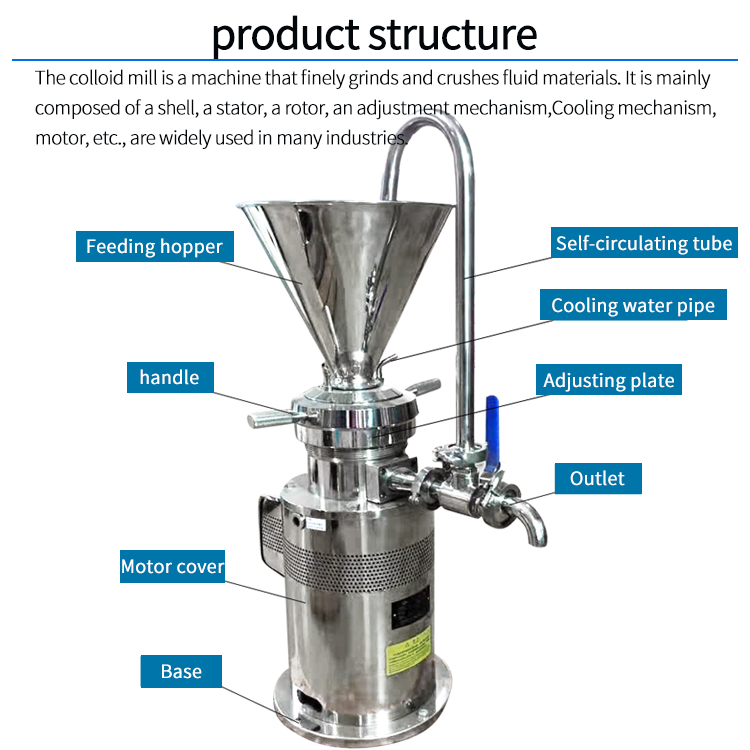

Colloid mill for grinding peanut butter and other sauces

Colloid mill

It is suitable for homogenization, emulsification, dispersion, mixing, crushing and grinding of various emulsions. Widely used in food (fruit pulp, fruit juice, protein milk, soy milk, milk tea, dairy products, beverages, etc.), pharmaceuticals (various syrups, nutrient solutions, Chinese patent medicines, paste medicines, etc.), daily chemicals (toothpaste, cosmetics, Detergents, etc.), chemicals (pigments, dyes, coatings, lubricants, petroleum catalysts, etc.), emulsified asphalt, coal flotation agents, ceramic shaft materials, nanomaterials and other industries.

The colloid mill is composed of stainless steel and semi-stainless steel colloid mill. Except for the motor and some parts, all the parts in contact with the material are made of high-strength stainless steel. In particular, the key dynamic and static grinding discs are reinforced, so they have good corrosion resistance and wear resistance. , so that the processed materials are pollution-free, hygienic and pure.

Colloid mill is a number of patented products: it has the characteristics of compact design, utility model, beautiful appearance, good sealing, stable performance, convenient operation, simple decoration, durability, wide application range and high production efficiency. It is the most ideal processing for fine materials. equipment. Except for the motor and some parts, all the parts in contact with the material are made of high-strength stainless steel. In particular, the key dynamic and static grinding discs are reinforced, so they have good corrosion resistance and wear resistance. , so that the processed materials are pollution-free, hygienic and pure.

Features:

1. Three-stage online dispersing emulsifier

2. Three-stage stator and rotor form

2G (coarse) 4M (medium) 6F (fine)

3. Perfect for stable homogeneous emulsions and suspensions

4. The dispersing head can be freely assembled, modular and easy to maintain

5. A concentrated particle size distribution in just one treatment

6. Stepless speed regulation (inverter)

7. All contact materials are made of 304

8. Compliant with CIP/SIP cleaning standards, suitable for food and pharmaceutical production

9. Obtained the 3A level certificate issued by the U.S. Food and Drug Administration (FDA)

Equipment series: mixer, mixer, disperser, emulsifier, shearing machine, homogenizer, grinder, colloid mill

Grinding Equipment, Homogenizing Equipment, Shearing Equipment, Emulsifying Equipment, Dispersing Equipment, Mixing Equipment, Stirring Equipment, Solid-Liquid Mixing Equipment, Powder-Liquid Mixing Equipment, Powder Mixer, Mixing Dispersing Machine, Dispersing Emulsifying Machine, Shearing Emulsifying Machine , emulsification homogenizer, shear homogenizer, mixing and stirring, high shear emulsifier, high shear disperser, high shear mixing equipment, high shear emulsification and dispersion equipment, high shear emulsification and homogenization equipment. Compared with the pressure type homogenizer, the colloid mill is first and foremost a centrifugal type equipment. It has the advantages of simple structure and convenient equipment maintenance.

Scope of application:

1. Food industry: aloe vera, pineapple, sesame, fruit tea, ice cream, moon cake filling, cream, jam, juice, soybean, bean paste, bean paste, peanut milk, protein milk, soy milk, dairy products, malt milk essence, essence, various beverages, etc.

2. Chemical industry: paints, pigments, dyes, coatings, lubricants, greases, diesel fuel, petroleum catalysts, emulsified asphalt, adhesives, detergents, plastics, glass fiber reinforced plastics, leather, emulsification, etc.

3. Daily chemicals: toothpaste, detergent, shampoo, shoe polish, advanced cosmetics, bath essence, soap, balsam, etc.

4. Pharmaceutical industry: various types of syrups, nutrient solutions, Chinese patent medicines, paste medicines, biological products, cod liver oil, pollen, royal jelly, vaccines, various ointments, various oral liquids, injections, intravenous drips, etc.

5. Construction industry: various coatings. Including interior and exterior wall coatings, anti-corrosion and waterproof coatings, cold porcelain coatings, colorful coatings, ceramic glazes, etc.

6. Other industries: plastic industry, textile industry, paper industry, coal flotation agent, nanomaterials and other industries have high-quality and environmentally friendly production needs.

Structural advantages:

1. Internal tooth structure, small size and low energy consumption; the colloid mill motor is only 55KW.

2. Imported stator and rotor core components, unique anti-corrosion and anti-wear materials, with a guaranteed life of more than 200,000 tons.

3. The colloid mill motor is controlled by a frequency converter, the current impact is small, and the speed can be adjusted according to requirements.

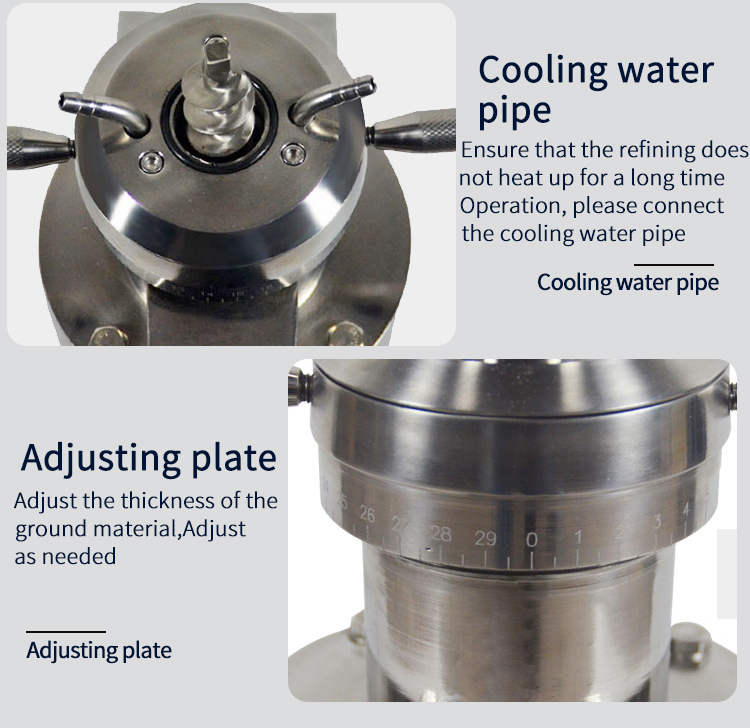

4. The colloid mill gap can be adjusted within the range of 0.1-5mm.

5. Asphalt with up to 20% polymer can be successfully overground at one time, the minimum particle size of SBS can reach 0.1μm, and the shear grinding capacity is 10 times that of ordinary colloid mills, which greatly shortens the residence time of asphalt at high temperature and prevents High temperature aging.

6. It can cut and grind various modified asphalt varieties such as SBS, SBR, EVA, PE, waste rubber powder and rock asphalt.

Factory inspection

1. Each colloid mill must be inspected and qualified by the inspection department of the manufacturer, and can only leave the factory after a certificate of conformity is attached.

2. Each colloid mill must be operated at rated speed for 30min before leaving the factory.

No-load test

, the product should meet the following requirements.

1. The machine runs normally and smoothly, without abnormal sound, and the operating device is flexible and reliable.

2. The connecting parts and fasteners shall not be loose.

3. For products produced in batches, at least two units should be randomly tested each year, and the test should be carried out according to the regulations of JB/T9820.3, and the results should meet the regulations.

4. When the ordering unit accepts the product, it should be accepted according to this standard. If unqualified, it should be re-submitted for acceptance after repairing by the manufacturer.

Under the condition that the user abides by the instruction manual of the mixer specified by the manufacturer, within 1 year from the date of purchase, if the damage occurs due to poor manufacturing quality, the manufacturer shall guarantee repair, replacement and return.

5. The quality of paint coating should be inspected according to the regulations of JB/T?5673.

3. Marking, packaging, transportation and storage

1. Each colloid mill should have a product label fixed in an obvious position, the label should comply with the regulations, and the label should indicate the following:

1) The name of the manufacturer;

2) Product name and model;

3) Spindle speed;

4) Productivity;

5) Supporting power;

6) Machine weight;

7) Product manufacturing number;

8) The date of manufacture of the product.

2. Mark the rotation direction of the rotor with a red arrow at the obvious position of the casing.

3. The colloid mill should be packaged before leaving the factory. The packaging should be convenient for transportation and ensure that the product is not damaged.

4. The accessories (spare parts and tools) supplied with the product should be complete.

5. Each product should be accompanied by the following documents:

1) packing list;

2) Product quality inspection certificate;

3) Product instruction manual;

4) User opinion questionnaire.

6. All documents are sealed in plastic bags and fixed in the box.

7. The colloid mill should be stored in a moisture-proof and rain-proof facility.

Colloid mill maintenance and repair

1. The colloid mill is a high-precision machine with a line speed of up to 20m/s and a very small gap between the grinding discs. After overhaul, it is necessary to use a dial indicator to correct the coaxiality error between the casing and the main shaft ≤ 0.05mm.

2. When repairing the machine, during the process of disassembly, installation and adjustment, it is not allowed to strike directly with the iron bell. Use a wooden hammer or a wooden block to tap lightly to avoid damaging the parts.

3. Seals of this machine: divided into static and dynamic seals. The static seal adopts an O-shaped rubber ring, and the dynamic seal adopts a hard mechanical combined seal. If the hard sealing surface is found to be scratched, it should be immediately

4. During the use process, regular maintenance should be carried out as appropriate according to the conditions of the processed materials.

5. For the maintenance and use of the motor, please refer to the motor instruction manual.

6. Most of the random spare parts are national standard and department standard parts.