Today we will introduce a dehydration equipment

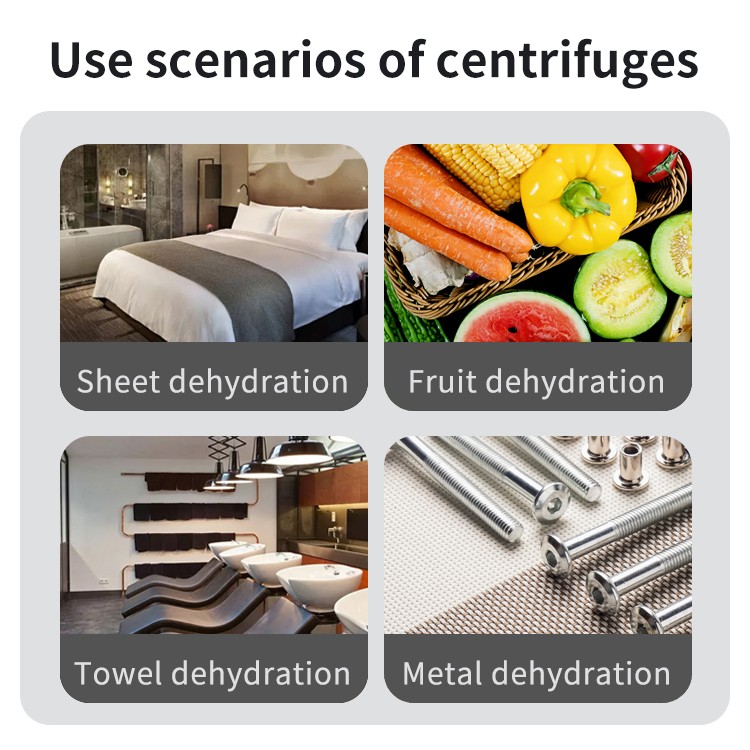

Industrial centrifugal dehydrators have the advantages of simple and reasonable structure, high efficiency, low wear and tear, low noise, and convenient use. To meet the demand for high-capacity solid-liquid separation, it is mainly used for various textile (needle) fabrics, clothing, chemical raw materials, latex products, etc. After washing, dehydration and drying. It is widely used in enterprises and units such as textile, printing and dyeing, clothing, hotels, hospitals, chemical and rubber products.

The structural characteristics of industrial centrifugal dehydrators:

1. Industrial centrifugal dehydrators are all equipped with a three legged suspension structure, which can reduce the shaking of the foundation during operation due to the unbalanced load inside the hub.

2. The shell and hub are all made of stainless steel plates, and the cage base and chassis are made of cast iron material. The water outlet pipe is located below the chassis.

3. The spindle is made of national standard steel through heat treatment and precision processing. One time molding technology with high concentricity ensures smooth operation of the entire machine.

4. The transmission part adopts triangular tape transmission, which is directly driven by the centrifugal starting wheel by the motor, which can slowly start the machine and gradually reach the design speed

Make the machine run smoothly.

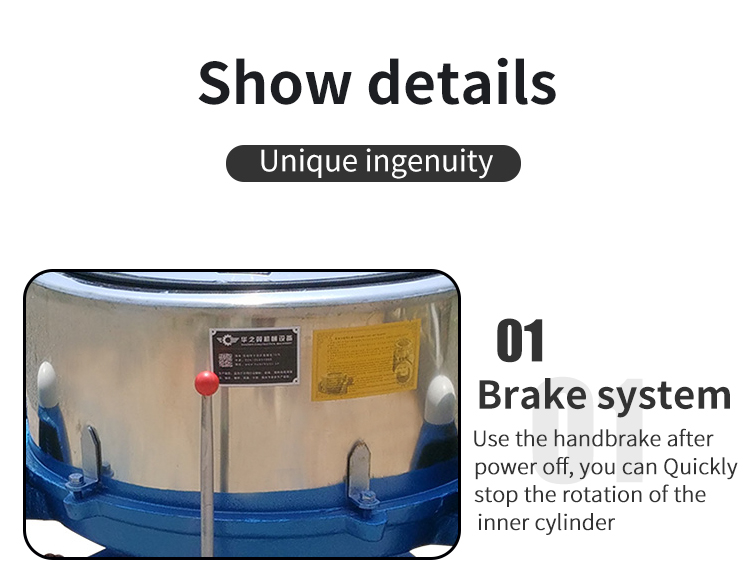

5. There is a brake opening and closing arm inside the machine, which has good braking performance and can make the machine stop rotating for a short time.

The three legged suspension structure consists of a triangular chassis, cast feet, circular chassis, drum, outer shell, motor, etc. The drum and outer shell are made of national standard stainless steel. Driven by triangular tape, the motor directly drives the starting wheel, causing the machine to start slowly. After a few seconds, it reaches the design speed, and the machine starts smoothly. After use, there is a braking device inside the machine. By turning the brake handle, the machine can stop running for a short period of time.